Abstract

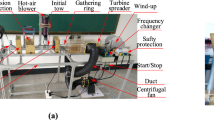

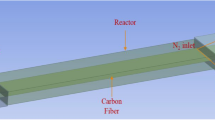

In this study, a three-dimensional (3-D) mathematical model of a fiber pneumatic spreader was successfully developed in the physical phenomena of the internal flow field by a far-field treatment at boundary conditions. The 3-D numerical analysis was carried out on incompressible fluid flows in the pneumatic spreader by using finite volume method combined with the k-ɛ turbulence model which solves Reynolds-averaged Naiver-Stokes equations. Characteristics of the flow field in the spreader at different service conditions are investigated by velocity and pressure distributions. Comparisons of numerical results with measured velocity and pressure distributions were made to determine the accuracy of the employed method. A good agreement was found in both qualitative and quantitative analysis. Fibers were spread on 1:1-scale model of the pneumatic spreader at various fiber transporting rates and air flow rates. Photography techniques were simultaneously used to record the procedures of fibers spread. The carbon fiber tow was easily spread out at service conditions. The performance was better than prior studies in one-dimensional orifice formulation. The results revealed details of the fiber spreading processes. Agreement among those results validated the assumptions inherent to the computational calculation and gave confidence to more complex geometries as well as flow fields. In other words, the use of numerical analysis in the internal flow field was useful for the fiber pneumatic spreader design.

Similar content being viewed by others

Abbreviations

- A :

-

cross-sectional area

- c 1, c 2, and c 1 :

-

empirical coefficient

- E :

-

empirical coefficient

- k :

-

turbulent kinetic energy

- p :

-

pressure

- t :

-

time

- \(\overline {u_i ^\prime u_j ^\prime } \) :

-

Reynolds stress tensor

- u′ i , u′ j :

-

fluctuation parts of the velocity

- u j :

-

velocity

- ū :

-

average velocity

- u + :

-

scaled velocity

- U, V, W :

-

velocity components

- V F :

-

fiber transported velocity

- x, y, z :

-

Cartesian coordinates

- y − :

-

dimensionless distance

- ɛ :

-

turbulent dissipation rate

- μ τ :

-

turbulent viscosity

- k :

-

Von Karman constant

- ξ, ζ, η :

-

curvilinear coordinate

- v :

-

molecular kinematic viscosity

- v T :

-

eddy viscosity

- ρ :

-

density

- σ K :

-

turbulent Prandtl number for k

- σ ɛ :

-

turbulent Prandtl number for ɛ

- τ :

-

shear stress

- \(\tilde \tau _{ij} \) :

-

Reynolds stress tensor

- ϕ :

-

general variable

- ▽:

-

del operation

- ϑ :

-

partial derivative

References

F. Delannay, L. Foryen, and A. Deruyttere: J. Mater. Sci., 1987, vol. 22, pp. 1–16.

R.V. Subramanian and A. Nyberg: J. Mater. Res., 1992, vol. 7 (3), pp. 677–88.

Li-Min Zhou, Yiu-Wing-Mai, and Caroline Baillie: J. Mater. Sci., 1994, vol. 29, pp. 5541–50.

Sunil G. Warrier and Ray Y. Lin: Scripta Metall. Mater., 1993, vol. 29, pp. 1513–18.

Zhenhia Xia, Yaohe Zhou, Zhiying Mao, and Baolu Shang: Metall. Trans. B, 1992, vol. 23B, pp. 295–302.

R. Asthana: J. Mater. Sci., 1998, vol. 33, pp. 1959–80.

G. Leonhardt, E. Kieselstein, H. Podlesak, E. Than, and A. Hofman: Mater. Sci. Eng., 1991, vol. A135, pp. 157–60.

Andreas Mortensen: Mater. Sci. Eng., 1991, vol. A135, pp. 1–11.

J.K. Yu, H.L. Li, and B.L. Shang: J. Mater. Sci., 1994, vol. 29, pp. 2641–47.

D. Huda, M.A. El Baradie, and M.S.J. Hashmi: J. Mater. Processing Technol., 1993, vol. 37, pp. 529–41.

Feng Wu and Jing Zhu: Composites Sci. Technol., 1997, vol. 57, pp. 661–67.

Susan Abraham, B.C. Pai, K.G. Satyanarayana, and V.K. Vaidyan: J. Mater. Sci., 1999, vol. 25, pp. 2839–45.

S. Abraham, B.C. Pai, and K.G. Satyanaryana: J. Mater. Sci., 1992, vol. 27, pp. 3479–86.

H.M. Cheng, A. Kitahara, S. Akiyama, K. Kobayashi, and B.L. Zhou: J. Mater. Sci., 1992, vol. 27, pp. 3617–23.

Yu-Qing Wang and Ben-Liam Zhou: J. Mater. Processing Technol., 1998, vol. 73, pp. 78–81.

R.J. Bobka and L.P. Lowell: Handbook of Composites, vol. 1 - Strong Fibres, W. Watt, and B. V. Perov, eds., Elsevier Science Publisher B.V., 1985, pp. 579–80.

D. Clark, N.J. Wadsworth, and W. Watt: Handbook of Composites, vol. 1 - Strong Fibres, W. Watt, and B. V. Perov, eds., Elsevier Science Publisher B.V., 1985, pp. 579–80.

Haining Yang, Mingyuan Gu, Weiji Jiang, and Guoding Zhang: J. Mater. Sci., 1996, vol. 31, pp. 1903–07.

Clare G. Daniels: U.S. Patent No. 3,873,389, Philco-Ford Corp., Philadelphia, PA, El Toro, CA, Mar. 25, 1975.

Paul E. McMahon, Tai-Shung Chung, and Lincoln Ying: U.S. Patent No. 4,871,491, BASF Structural Materials, Inc., Charlotte, N.C., Oct. 3, 1989.

John N. Hall: U.S. Patent No. 3,704,485, Hercules Incorporated, Wilmington, DE, Brookside Park, DE, Dec. 5, 1972.

Robert M. Baucom and Joseph M. Marchello: Sampe Q., 1990, July, pp. 14–19.

J.F. Tompson: Numerical Grid Generation, Elsevier, New York, NY, 1982.

E.B. Launder and B.D. Spalding: Mathematical Models of Turbulence, Academic Press, London, 1972.

CFX-F3D Version 4.1 User Manual, Harwell Laboratory, Oxfordshire, U.K., 1995, Oct.

G.J. Sturgess, S.A. Sayed, and K.R. McManus: Int. J. Turbo Jet Engines, 1986, vol. 33, pp. 43–55.

J.K. Eaton and J.P. Johnston: AIAA J., 1981, vol. 19 (9), pp. 1093–1100.

M.C. Rhie and L.W. Chow: AIAA J., 1983, vol. 21, pp. 1525–32.

S.V. Patankar and B.D. Spalding: Int. J. Heat Mass Transfer, 1972, vol. 15, pp. 1787–92.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, J.C., Chao, C.G. Numerical and experimental study of internal flow field for a carbon fiber tow pneumatic spreader. Metall Mater Trans B 32, 329–339 (2001). https://doi.org/10.1007/s11663-001-0056-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-001-0056-0