Abstract

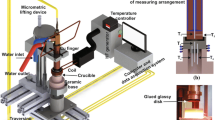

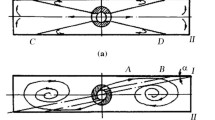

Using implanted thermocouples, and an inverse heat-transfer technique, heat fluxes and associated heat-transfer coefficients during the solidification of steel in a pilot scale 0.6-m-diameter twin roll caster, whose copper contact surfaces had been treated with a propriety coating, were measured. It was found that heat fluxes during initial contact of liquid steel with the rolls were low, rising to maximum values of about 5 to 6 MW per square meter halfway down the sump of liquid steel, but then diminishing toward zero as the strip approached the roll nip. These results corresponded to roll speeds of some 7 m/min, strip thicknesses of 7 mm, and a roll separating force of 20 kN. For higher speeds and thinner strip, a secondary peak in the heat flux was observed. Associated microstructures revealed acicular ferrite, large prior austenite grains, and secondary dendrite arm spacings in keeping with measurements.

In parallel experiments simulating a single belt horizontal caster, heat fluxes from strips of various aluminum alloys to coated and uncoated steel and copper substrates were measured. Under these conditions, peak heat fluxes were recorded during the period of initial contact, and depending on the coating characteristics, these reduced to a lower plateau before declining, or continuously decreased toward zero, corresponding to complete solidification of the strip.

A theoretical analysis of the maximum heat-transfer rates that can be expected given perfect thermal contact of metal with the rolls, and its moderations by gas films, and substrate coatings illustrates the dominant role of the gas film and the need for dynamic heat flux measurements for quantitative modeling of fluid flows and solidification phenomena in thin strip casting operations. A model for air gap formation is proposed, based on viscous laminar flows within the gas films. Predicted thicknesses are in reasonable accord with those deduced on the basis of heat flux measurements.

Similar content being viewed by others

References

N.A. Holmberg: Steel Res., 1998, vol. 68, pp. 22–27.

A. Garcia and M. Prates: Metall. Trans. B, 1978, vol. 9B, pp. 449–57.

A. Garcia, T.W. Clyne, and M. Prates: Metall. Trans. B, 1979, vol. 10B, pp. 85–92.

J. Lipton, A. Garcia, and W. Heinemann: Arch. Eisenhúttenwes., 1982, vol. 53, pp. 469–73.

M. Prates and H. Biloni: Metall. Trans. B, 1972, vol. 3B, pp. 1501–10.

J.V. Beck: Int. J. Heat Mass Transfer, 1970, vol. 13, pp. 703–16.

K. Ho and R.D. Pehlke: AFS Trans., 1983, pp. 689–98.

K. Ho and R.D. Pehlke: AFS Trans., 1984, pp. 587–97.

K. Ho and R.D. Pehlke: Metall. Trans. B, 1985, vol. 6B, pp. 585–94.

Y. Nishida, W. Droste, and S. Engler: Metall. Trans. B, 1986, vol. 17B, pp. 883–44.

T.S.P. Kumar and K.N. Prabhu: Metall. Trans. B, 1991, vol. 22B, pp. 717–27.

M. Krishnan and D.G.R. Sharma: AFS Trans., 1994, vol. 102, pp. 769–74.

N.A. El-Mahallawy and A.M. Assar: J. Mater. Sci. Lett., 1988, vol. 7, pp. 205–08.

N.A. El-Mahallawy and A.M. Assar: J. Mater. Sci., 1991, vol. 26, pp. 1729–33.

A.M. Assar: J. Mater. Sci. Lett., 1992, vol. 11, pp. 601–06.

N.A. El-Mahallawy, M.A. Taha, A.M. Assar, and R.M. Hamouda: Mater. Sci. Technol., 1993, vol. 9, pp. 691–97.

A.M. Assar: Mater. Sci. Technol., 1997, vol. 13, pp. 701–03.

J.C. Hwang, H.T. Chuang, S.H. Jong, and W.S. Hwang: AFS Trans., 1994, pp. 877–83.

P. Schmidt: Mater. Sci. Eng., 1993, vol. A173, pp. 271–74.

F. Lau, W.B. Lee, S.M. Xiong, and B.C. Liu: J. Mater. Proc. Technol., 1998, vol. 79, pp. 25–29.

S.P. Mehrotra, A. Chakravarty, and P. Singh: Steel Res., 1997, vol. 68, pp. 201–08.

W.D. Griffiths: Metall. Trans. B, 1999, vol. 30B, pp. 473–82.

K.H. Spitzer: Int. J. Heat Mass Transfer, 1991, vol. 34, pp. 1969–74.

S.J. Chen, R.C. Ren, and A.A. Tseng: J. Mater. Proc. Manufacturing Sci., 1995, vol. 3, pp. 373–86.

P.G.Q. Netto, R.P. Tavares, and R.I.L. Guthrie: Light Met., 1997, pp. 393–407.

C.A. Muojekwu, I.V. Samarasekera, and J.K. Brimacombe: Metall. Mater. Trans. B, 1995, vol. 26B, pp 361–82.

K.N. Prabhu, S.A. Kumar, and N. Venkataraman: AFS Trans., 1994, pp. 827–32.

E. Velasco, J. Talamantes, S. Cano, S. Valtierra, J.F. Mojica, and R. Colas: Metall. Trans. B, 1999, vol. 30B, pp. 773–78.

S.J. Chen, R.C. Ren, and A.A. Tseng: J. Mater. Proc. Manufacturing Sci. 1995, vol. 3, pp. 373–86.

L. Strezov and L. Herbertson: Iron Steel Inst. Jpn. Int., 1998, vol. 38, pp. 959–66.

R.P. Tavares, M. Isac, and R.I.L. Guthrie: Iron Steel Inst. Jpn. Int., 1998, vol. 38, pp. 1353–61.

K.A. Woodbury: Int. J. Heat Mass Transfer, 1990, vol. 33 (12), p. 2641.

R.P. Tavares: Ph.D. Thesis, McGill University, Montreal, 1997.

J.V. Beck, B. Blackwell, and C.R. St. Clair, Jr.: Inverse Heat Conduction. Ill-Posed Problems, John Wiley & Sons, New York, NY, 1985.

W. Reichelt, U. Urlau, R. Nystrom, and E. Burstorm: Proc. Metec 94, 2nd Eur. Conf. on Continuous Casting, Düsseldorf, 1994.

P.G.Q. Netto, R.P. Tavares, and R.I.L. Guthrie: Internal Report McGill University, Montreal, 1996.

C. Jefferies: Ph.D. Thesis, McGill University, Montreal, 1995, p. 1.

G.-X. Wang and E.F. Matthys: Trans. ASME — J. Heat Transfer, 1996, vol. 118, pp. 157–63.

T. Mizoguchi, K. Miyazawa, and Y. Ueshima: Tetsu-to-Hagané, 1994, vol. 80 (1), pp. 36–41.

T. Yamauchi, T. Nakanori, M. Hasegawa, T. Yabuki, and N. Ohnishi: Trans. Iron Steel Inst. Jpn., 1988, vol. 28 (1), pp. 23–27.

A.C. Rapier, T.M. Jones, and J.E. Mcintosh: Int. J. Heat Mass Transfer, 1963, vol. 6, pp. 397–416.

M.C. Flemings: Metall. Trans. B, 1991, vol. 22B, pp. 269–93.

G.E. Dieter: Mechanical Metallurgy, McGraw-Hill, New York, NY, 1983.

G.-X. Wang and E.F. Matthys: in Melt Spinning. Strip Casting and Slab Casting, E.F. Matthys and W.G. Truckner, eds., TMS, Warrendale, PA, 1996, pp. 205–36.

B. Farouk, D. Apelian, and Y.G. Kim: Metall. Trans. B, 23B (1992), 477–92.

H. Todoroki, R. Lertarom, A.W. Cramb, and T. Suzuki: ISS Trans., 1999, Apr., pp. 57–71.

Author information

Authors and Affiliations

Additional information

This article is based on a presentation made in the “Geoffrey Belton Memorial Symposium,” held in January 2000, in Sydney, Australia, under the joint sponsorship of ISS and TMS.

Rights and permissions

About this article

Cite this article

Guthrie, R.I.L., Isac, M., Kim, J.S. et al. Measurements, simulations, and analyses of instantaneous heat fluxes from solidifying steels to the surfaces of twin roll casters and of aluminum to plasma-coated metal substrates. Metall Mater Trans B 31, 1031–1047 (2000). https://doi.org/10.1007/s11663-000-0079-y

Issue Date:

DOI: https://doi.org/10.1007/s11663-000-0079-y