Abstract

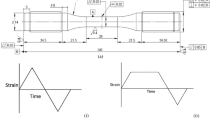

The nickel-base alloys IN 617 and HAYNES 230 for welded high-temperature components have been subjected to thermal fatigue (TF) loading. In a series of TF tests in air, single wedge specimens were induction heated and compressed-air cooled at the leading edge for various temperature cycles between 200 °C and either 850 °C, 950 °C, or 1050 °C. The test rigs permitted simultaneous measurements of temperature and total strain along the edge of specimen during TF cycling. Both materials have been tested in conditions relevant for hot path components in the gas turbines, e.g., “as delivered,” “welded,” and “welded + notched”. Under identical temperature cycles and thermal gradients, HAYNES 230 showed a higher TF strength than IN 617 in the as-delivered condition. It is suggested that this advantage of HAYNES 230 is primarily related to its lower value of the relevant combination of properties of this alloy: coefficient of thermal expansion, thermal conductivity, elastic modulus, ultimate tensile strength, taken at maximal operating temperature. In addition, the advantage of the HAYNES 230 is described by a lower plastic strain, which is induced at the wedge region during TF loading. Moreover, microstructural details of crack initiation, crack propagation, and reactions with the gaseous environment play an important role. Both alloys investigated in the present work showed plastic deformation with a maximum in the central zone of the wedge tip. In this zone, slip bands and grain distortion occurred, whereas both ends of the wedge tip free of visible plastic deformation. The TF cycles led to multiple transgranular crack initiation and propagation. In welded specimens of IN 617 and HAYNES 230, cracks appeared first in the center of the weld. The susceptibility of welds to TF cracking depends considerably on the weld filler and the surface quality. It was shown for HAYNES 230 that a mismatched weld could reduce the TF life to less than 50 pct of non-welded specimens. The lower TF-fatigue strength of the welded specimens can be explained by the difficulty of the cast alloy in the welded zone to accommodate the repeated thermal shocks by plastic deformation. Notches introduced in the heat-affected zone (depth about 0.1 mm) reduced the TF life of both alloys by a factor as high as 4. The thermal fatigue strength of the welded material can almost reach the values of the base alloy provided the use of matching electrodes, post-weld heat treatment, and grinding off the weld beads is carefully executed.

Similar content being viewed by others

References

T.H. Bassford and T.V. Schill: Applications of Materials for Pressure Vessels and Piping, MCP-10, ASME, New York, NY, 1979, pp. 1–12.

M.F. Rothman: Modern Alloys in Gas Turbines, World Aerospace Profile, Sterling Publications Ltd., London, 1988.

D.L. Klarstrom, H.M. Tawancy, and M.F. Rothman: Proc. Superalloys 1984, TMS-AIME, Seven Springs, PA, 1984, pp. 553–62.

V.P. Swaminathan and S.J. Lukezich: Degradation of Transition Duct Alloys in Gas Turbines, Proc. ASM 1993, Materials Congress, Materials Week ’93, Pittsburgh, PA, Oct. 17–21, 1993, pp. 99–111.

S.K. Srivastava and D.L. Klarstrom: Gas Turbine and Aeroengine Congress and Exposition, Brussels, June 11–14, 1990, ASME, New York, NY, p. 7.

M. Diehl and C.M. Sonsino: 3rd Int. Conf. on Biaxial/Multiaxial Fatigue, Stuttgart, Germany Apr. 3–6, 1989.

K.S. Vecchio, M.D. Fitzpatrick, and D. Klarstrom: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 673–690.

C. Sommer, M. Bayerlein, and W. Hartnagel: Proc. 81st AGARD SMP Panel, Thermal Mechanical Fatigue of Aircraft Engine Materials, Banff, Canada, Oct. 2–4, 1995, North Atlantic Treaty Organisation, published in CP-569, pp. 11-1–11-12.

J.Y. Guedou and Y. Honnorat: in Thermomechanical Fatigue Behaviour of Materials, H. Sehitoglu, ed., ASTM STP1186, ASTM, Philadelphia, PA, 1993, pp. 157–75.

C.C. Engler Pinto, F. Meyer-Olbersleben, and F. Rézaï-Aria: in Fatigue under Thermal and Mechanical Loading: Mechanisms, Mechanics and Modelling, J. Bressers and L. Rémy, eds., Kluwer Academic Publishers, London, 1995, pp. 151–157.

F. Meyer-Olbersleben, C.C. Engler Pinto, and F. Rézaï-Aria: in Thermo-Mechanical Fatigue Behavior of Materials: 2nd Volume, M.J. Verrilli and M.G. Castelli, eds., ASTM STP1263, ASTM, Philadelphia, PA, 1996, pp. 41–55.

Specific Metals and Alloys, vol. 2, Metals Handbook, ASTM INTERNATIONAL, Materials Park, OH, 1990, pp. 432–43.

B. Kazmierkzak, M. Prignon, CH. Lecompte-Mertens, and D. Coutsouradis: High Temperature Materials for Power Engineering 1990, E. Bachelet et al., Kluwer Academic Publishers, Dordrecht, 1990, pp. 131–42.

N. Kasik: “Testing of the Inner-Liners from Haynes 230 and from IN 617 after About 20,000 Equivalent Operating Hours,” ABB Internal Report, ABB Power Generation Ltd., Baden, Switzerland, 1997.

F. Meyer-Olbersleben and F. Rézaï-Aria: Federal Institute of Technology, Lausanne, Switzerland, unpublished research, 1995.

O. Mallet, H. Kaguchi, B. Ilschner, F. Meyer-Olbersleben, K. Nikbin, F. Rézaï-Aria, and G.A. Webster: Int. J. Fatigue, 1995, vol. 17 (2), pp. 129–34.

M. Blümm, F. Meyer-Olbersleben, and F. Rézaï-Aria: in Fatigue under Thermal and Mechanical Loading: Mechanisms, Mechanics and Modelling, J. Bressers and L. Rémy, eds., Kluwer Academic Publishers, London, 1995, pp. 131–39.

S. Suresh: Fatigue of Materials, Cambridge University Press, Cambridge, United Kingdom, 1991, pp. 64–66.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Meyer-Olbersleben, F., Kasik, N., Ilschner, B. et al. The thermal fatigue behavior of the combustor alloys In 617 and HAYNES 230 before and after welding. Metall Mater Trans A 30, 981–989 (1999). https://doi.org/10.1007/s11661-999-0151-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-999-0151-4