Abstract

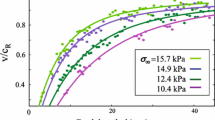

A model for predicting the crack closing stress intensity factor for roughness-induced closure of fatigue cracks is developed based on a two-dimensional approach considering crack opening and closure of an idealized crack path. The model highlights the contribution of irreversible cyclic planar slip at the crack tip, and is extended to real cases describing roughness-induced crack closure as a function of fracture surface roughness parameters at low ΔK levels where planar slip prevails. The resulting equation indicates that roughness-induced crack closure depends on the maximum stress intensity factor, the standard deviation of heights as well as the standard deviation of angles of the crack profile elements, and the yield stress of the material. Comparison between the prediction of the model and experimental data of K cl for lamellar microstructures of Ti-2.5 Cu as well as TIMETAL 1100 shows good agreement.

Similar content being viewed by others

Abbreviations

- b:

-

the Burgers vector of a dislocation

- B:

-

the total Burgers vector of an inverted pileup of dislocations at crack tip along the slip plane

- c :

-

the size of dislocation free zone ahead of the crack tip

- D ol :

-

local shear displacement at crack tip along the active slip plane at K cl

- D m :

-

maximum local shear displacement along active slip plane at the crack tip in a load cycle

- E :

-

modulus of elasticity

- K cl :

-

crack closing stress intensity factor

- k I :

-

local mode I stress intensity factor at the tip of a kinked crack

- k II :

-

local mode II stress intensity factor at the tip of a kinked crack

- K max :

-

maximum stress intensity factor in a load cycle

- ΔK :

-

stress intensity factor range

- ΔK tr :

-

stress intensity factor range, where a transition in fracture mechanism takes place

- l e :

-

effective slip length of dislocation resulting in local mode II displacement

- l s :

-

maximum slip length of dislocations

- \(\bar l_e \) :

-

average effective slip length of dislocations

- \(\bar l_f \) :

-

average facet length (arithmetic mean length of linear elements of the crack path profile)

- R :

-

the size of the plastic zone along the slip plane (at R ahead of crack tip, β(x) turns to be zero)

- R L :

-

linear roughness parameter

- S S :

-

standard deviation of the angular distribution of linear elements of the crack path profile

- S H :

-

standard deviation of the height distribution of linear elements of the crack path profile

- β(x):

-

local Burgers vector density in case the discrete dislocations are replaced as continuous linear distribution (db = β(x)dx)

- δ ol :

-

displacement between the two mating crack surfaces in the applied mode I loading direction at K ol

- τ :

-

the stress at crack tip due to elastic crack tip stress field (K field)

- θ :

-

angle denoting the extent of ideal crack path deflection

- θ eq :

-

equivalent orientation angle of real crack path profile, θ eq = arccos (1/R L

- v :

-

Poisson’s ratio

- μ :

-

shear modulus

- σ y :

-

yield strength

- CL:

-

coarse lamellar microstructure of Ti-2.5Cu

- CTOD:

-

crack tip opening displacement

- FL:

-

fine lamellar microstructure of Ti-2.5Cu

- LC-1100:

-

lamellar microstructure with coarse prior-β grains of TIMETAL 1100

- LF-1100:

-

lamellar microstructure with fine prior-β grains of TIMETAL 1100

References

W. Elber: Eng. Fract. Mech., 1970, vol. 2, pp. 37–45.

W. Elber: Damage Tolerance in Aircraft Structures, ASTM STP 486, ASTM, Philadelphia, PA, 1971, pp. 230–42.

S. Suresh: in Materials Science and Technology, vol. 6, Plastic Deformation and Fracture of Materials, R.W. Cahn, P. Haasen, and E.J. Kramer, eds., VCH Verlagsgesellschaft mbH, Weinheim, 1993, pp. 281–350.

S. Suresh, G.F. Zamiski, and R.O. Ritchie: Metall. Trans. A, 1981, vol. 12A, pp. 1435–43.

H. Kobayashi, H. Tsuji, and K.D. Park: in Fracture and Strength ’90, Key Engineering Materials, Vols. 51 and 52, K.Y. Lee and H. Takahashi, eds., Trans Tech Publications, Zürich, 1990, pp. 355–60.

R.O. Ritchie and S. Suresh: Metall. Trans. A, 1982, vol. 13A, pp. 937–40.

S. Suresh and R.O. Ritchie: Metall. Trans. A, 1982, vol. 13A, pp. 1627–31.

B. Tomkins: Met. Sci., 1979, vol. 13, pp. 387–95.

B.A. Bilby, G.E. Cardew, and I.C. Haward: in Fracture 1977, D.M.R. Taplin, ed., University of Waterloo Press, Waterloo, 1977, pp. 197–201.

S. Suresh: Metall. Trans. A, 1983, vol. 14A, pp. 2375–85.

S. Suresh and C.F. Shih: Int. J. Fract., 1986, vol. 30, pp. 237–59.

N. Walker and C.J. Beevers: Fatigue Eng. Mater. Struct., 1979, vol. 1, pp. 135–48.

S. Suresh: Metall. Trans. A, 1985, vol. 16A, pp. 249–60.

J. Wasén and B. Karlsson: in Fatigue 90, H. Kitagawa and T. Tanaka, eds., Materials and Component Engineering Publications Ltd., Birmingham, 1990, pp. 1289–94.

L. Sun, S. Li, Q. Zang, and Z. Wang: Scripta Metall. Mater., 1995, vol. 32, pp. 517–21.

J. LLorca: in Fatigue 90, H. Kitagawa and T. Tanaka, eds., Materials and Component Engineering Publications Ltd., Birmingham, 1990, pp. 1301–06.

J. LLorca: Fatigue Fract. Eng. Mater. Struct., 1992, vol. 15, pp. 655–69.

J. Wasén, B. Karlsson, and K. Hamberg: Acta Stereol., 1987, vol. 6, pp. 199–204.

J. Wasén: Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, 1988.

B. Karlsson and J. Wasén: Proc. 7th European Conf. on Fracture, EMAS, Warley, 1988, pp. 573–92.

B. Karlsson and J. Wasén: Proc. 7th Int. Conf. on Fracture, Pergamon Press, Oxford, United Kingdom, 1989, pp. 3383–90.

J. Wasén, K. Hamberg, and B. Karlsson: Mater. Sci. Eng. A, 1988, vol. 102, pp. 217–26.

J. Wasén and B. Karlsson: Int. J. Fatigue, 1989, vol. 11, pp. 395–405.

W.W. Gerberich, W. Yu, and K. Esaklul: Metall. Trans. A, 1984, vol. 15A, pp. 875–88.

A.J. Wilkinson and S.G. Roberts: Scripta Mater., 1996, vol. 35, pp. 1365–71.

J. Weertman, I.-H. Lin, and R. Thomson: Acta Metall., 1983, vol. 31, pp. 473–82.

R. Thomson: Scripta Metall., 1986, vol. 20, pp. 1473–76.

R. Thomson: Solid State Phys., 1986, vol. 39, pp. 1–129.

S.-H. Dai and J.C.M. Li: Scripta Metall., 1982, vol. vol. 16, pp. 183–88.

Y.-H. Chiao and D.R. Clarke: Acta Metall., 1989, vol. 37, pp. 203–19.

B.A. Bilby, A.H. Cottrell, and K.H. Swinden: Proc. R. Soc., 1963, vol. A272, pp. 304–14.

A. Toshimitsu Yokobori, T. Isogai, and T. Yokobori: Acta Metall. Mater., 1993, vol. 41, pp. 1405–11.

S.M. Ohr: Mater. Sci. Eng., 1985, vol. 72, pp. 1–35.

S.-H. Wang: Ph.D. Thesis, Technical University of Darmstadt, Darmstadt, Germany, 1997.

B. Karlsson and J. Wasén: in Fatigue 90, H. Kitagawa and T. Tanaka, eds., Materials and Component Engineering Publications Ltd., Birmingham, 1990, pp. 279–84.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, SH., Müller, C. & Exner, H.E. A model for roughness-induced fatigue crack closure. Metall Mater Trans A 29, 1933–1939 (1998). https://doi.org/10.1007/s11661-998-0018-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-998-0018-0