Abstract

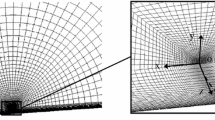

An attempt has been made to visually simulate fatigue crack propagation from a precrack. An integrated program was developed for this purpose. The crack-tip shape was determined at four load positions in the first load cycle. The final shape was a blunt front with an “ear” profile at the precrack tip. A more general model, schematically illustrating the mechanism of fatigue crack growth and striation formation in a ductile material, was proposed based on this simulation. According to the present model, fatigue crack growth is an intermittent process; cyclic plastic shear strain is the driving force applied to both state I and II crack growth. No fracture mode transition occurs between the two stages in the present study. The crack growth direction alternates, moving up and down successively, producing fatigue striations. A brief examination has been made of the crack growth path in a ductile two-phase material.

Similar content being viewed by others

References

P. Forsyth, J.E. Rider, and D.A. Ryder: Metallurgia, 1961, vol. 63, pp. 117–27.

C. Laird and G.C. Smith: Phil. Mag., 1962, vol. 7 (77), pp. 847–57.

P. Neumann: Acta Metall., 1974, vol. 22, p. 1155.

A.S. Kuo and H.W. Liu: Scripta Metall., 1976, vol. 10, pp. 723–28.

Z.P. Bazant and F.B. Lin: J. Struct. Eng., 1988, vol. 114 (11), pp. 2493–2510.

Xon Zhang et al.: Eng. Fract. Mech., 1992, vol. 42 (2), pp. 305–21.

M.A. Aminpour and K.a. Holsapple: Eng. Fract. Mech., 1991, vol. 39 (3), pp. 451–68.

G.M. Seed and K.J. Miller: Fat. Fract. Eng. Mat. Struct., 1991, vol. 14 (2–3), pp. 259–75.

B.A. Bilby, I.C. Harward, and Z.H. Li: Eighth Report on the Stability of Cracks in Tough Materials, The University of Sheffield, Sheffield, 1990.

P.A. Wawrzynek and A.R. Ingraffea: Theor. Appl. Fract. Mech., 1987, vol. 8, pp. 137–50.

J.S. Park and H. Margolin: Metall. Trans. IIA, 1984, vol. 15A, pp. 155–71.

P. Lalor and H. Sehitoglu: ASTM STP 982, ASTM, Philadelphia, PA, 1988, pp. 342–60.

Bucek and Herakovich: Eng. Fract. Mech., 1987, vol. 26 (2), pp. 185–201.

P. Neumann: Acta Metall., 1974, vol. 22, p. 1155.

H. Margolin and H.L. Hoo: Proc., Microstructure Fracture Toughness and Fatigue Crack Growth Rate in Titanium Alloy, CO, Cincinnati, OH, 1987, pp. 131–36.

A.J. Krasowsky and V.A. Stepanenko: Int. J. Fat., 1979, vol. 15 (3), pp. 211–13

B. Tomkins: Phil. Mag., 1968, vol. 18 (155), pp. 1041–66.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, S., Margolin, H. & Lin, F. Visual simulation of fatigue crack growth. Metall Mater Trans A 29, 1923–1931 (1998). https://doi.org/10.1007/s11661-998-0017-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-998-0017-1