Abstract

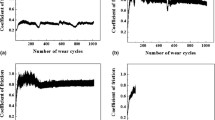

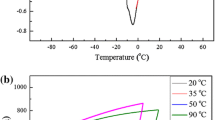

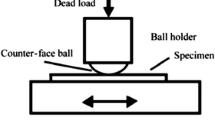

The wear characteristics of TiNi shape memory alloys against Cr-steel have been studied. Experimental results indicate that the Ti49Ni51 alloy can exhibit a better wear resistance than Ti50Ni50 alloy due to their higher hardness and pseudoelastic behaviors. Four main mechanisms, adhesion, abrasion, surface fatigue, and brinelling, are found to have important contributions to the wear characteristics of TiNi alloys. The weight loss increases with increasing wear load and sliding distance but decreases with increasing sliding speed. The contact area during sliding wear will be increased due to the variant accommodation and/or pseudoelasticity and, hence, will reduce the average compressive stress and wear damage. Variant accommodation and/or pseudoelasticity can also stabilize the crack tips and hinder crack propagation, hence improving the wear characteristics of TiNi alloys.

Similar content being viewed by others

References

S. Miyazaki, K. Otsuka, and Y. Suzuki: Scripta Metall., 1981, vol. 15, pp. 287–92.

S. Miyazaki, Y. Ohmi, K. Otsuka, and Y. Suzuki: Proc. ICOMAT-82, J. Phys., 1982, vol. 43, pp. C4-255–C4-260.

S. Miyazaki, T. Imai, Y. Igo, and K. Otsuka: Metall. Trans. A, 1986, vol. 17A, pp. 115–20.

K.N. Melton and O. Mercier: Acta Metall., 1979, vol. 27, pp. 137–44.

Y. Oshida and S. Miyazaki: Corr. Eng., 1991, vol. 40, pp. 1009–25.

L.S. Castleman and S.M. Motzkin: in Biocompatibility of Clinical Implant Materials, D.F. Williams, ed., CRC Press, Boca Raton, FL, 1981, pp. 129–54.

H.C. Lin, S.K. Wu, and M.T. Yeh: Metall. Trans. A, 1993, vol. 24A, pp. 2189–94.

H.C. Lin, S.K. Wu, and Y.C. Chang: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 851–58.

J.L. Jin and H.L. Wang: Acta Metall. Sinica, 1988, vol. 24, pp. A66-A69.

D.Y. Li: Scripta Metall., 1996, vol. 34, pp. 195–200.

P. Clayton: Wear, 1993, vols. 162–164, pp. 202–10.

J. Singh and A.T. Alpas: Wear, 1995, vols. 181–183, pp. 302–11.

Y. Suzuki and T. Kuroyanagi: FAEDIC-NT, Titanium Zirconium, 1979, vol. 27, pp. 67–73.

Y. Shida and Y. Sugimoto: Wear, 1991, vol. 146, pp. 219–28.

J. Halling: Introduction to Tribology, Wykehan Publications Ltd., London, 1976.

O. Vingsbo: Wear of Materials, ASME, New York, NY, 1979, pp. 620–35.

I.M. Hutchings: Tribology: Friction and Wear of Engineering Materials, CRC Press, Boca Raton, FL, 1992, pp. 82–85.

T.H. Courtney: Mechanical Behavior of Materials, McGraw-Hill Publishing Co., New York, NY, 1990, pp. 16–17.

H.C. Lin and S.K. Wu: Metall. Trans. A, 1993, vol. 24A, pp. 293–99.

R.S. Cowan and W.O. Winer: in ASM Handbook, vol. 18, Friction, Lubrication, and Wear Technology, P. Blau, ed., Materials Park, OH, 1992, p. 39.

I. Kleis: Z. Werkstofftech., 1984, vol. 15, pp. 49–58.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, H.C., He, J.L., Chen, K.C. et al. Wear characteristics of TiNi shape memory alloys. Metall Mater Trans A 28, 1871–1877 (1997). https://doi.org/10.1007/s11661-997-0117-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-997-0117-3