Abstract

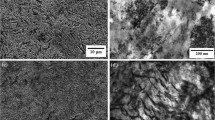

Two low-alloy quenched-tempered steels (#1 steel and #2 steel) are designed and comparatively studied to achieve ultrahigh yield strength (above 2000 MPa) at relatively low material and process costs. #1 steel and #2 steel have chemical compositions (wt pct) of 0.62 C, 1.62 Si, 0.78 Mn, 1.05 Cr, and 0.18 V and 0.55 C, 1.74 Si, 0.67 Mn, 1.12 Cr, 0.14 V, 0.21 Ni, and 0.20 Mo, respectively. The two steels are heated to 950 °C for 30 minutes, oil quenched, tempered at 240 to 440 °C for 90 minutes and water cooled. Under the same heat treatment parameters, the two steels have basically the same strength (tensile strength 2100 to 2400 MPa; yield strength 1950 to 2100 MPa). Interestingly, as the tempering temperature decreases from 440 °C to 240 °C, the elongation of #1 steel decreases from 10.7 to 1.8 pct, but that of #2 steel is quite stable at ~ 10 pct. #2 Steel has a high tempering resistance, and χ-carbide precipitation of #2 steel is significantly suppressed during tempering. Moreover, when tempering at 240 to 400 °C, the austenite volume fraction of #2 steel is higher than that in the quenched state. The reduction in carbide precipitation contributes to carbon segregation at martensite lath boundaries and other locations, and it may promote the formation of reversed austenite during tempering, which is revealed by 3D atom probe tomography (APT). The excellent mechanical properties of #2 steel are mainly related to the reversed austenite, the fine-grained microstructure of the martensite matrix and the reduced carbides acting as crack initiation sites.

Similar content being viewed by others

References

H.J. Kong, C. Xu, C.C. Bu, C. Da, J.H. Luan, Z.B. Jiao, G. Chen, and C.T. Liu: Acta Mater., 1993, vol. 172, pp. 150–60.

Y.H. Gao, S.Z. Liu, X.B. Hu, Q.Q. Ren, Y. Li, V.P. Dravid, and C.X. Wang: Mater. Sci. Eng. A, 2019, vol. 759, pp. 298–302.

P.M. Machmeier, C.D. Little, M.H. Horowitz, and R.P. Oates: Met. Technol., 1979, vol. 6, pp. 291–96.

R. Ayer and P.M. Machmeier: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2510–17.

D. Raabe, D. Ponge, O. Dmitrieva, and B. Sander: Scripta Mater., 2009, vol. 60, pp. 1141–44.

S. Jiang, H. Wang, Y. Wu, X. Liu, H. Chen, M. Yao, B. Gault, D. Ponge, D. Raabe, A. Hirata, M. Chen, Y. Wang, and Z. Lu: Nature, 2017, vol. 544, pp. 460–64.

M. Niu, G. Zhou, W. Wang, M.B. Shahzad, Y. Shan, and K. Yang: Acta Mater., 2019, vol. 179, pp. 296–307.

T. Liu, Z. Cao, H. Wang, G. Wu, J. Jin, and W. Cao: Scripta Mater., 2020, vol. 178, pp. 285–89.

H. Zhang, M. Sun, Y. Liu, D. Ma, B. Xu, M. Huang, D. Li, and Y. Li: Acta Mater., 2021, vol. 211, p. 116878.

B.B. He, L. Liu, and M.X. Huang: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 3167–72.

W.W. Sun, Y.X. Wu, S.C. Yang, and C.R. Hutchinson: Scripta Mater., 2018, vol. 146, pp. 60–63.

B. He, B. Hu, H. Yen, G. Cheng, Z. Wang, H. Luo, and M. Huang: Science, 2017, vol. 357, pp. 1029–32.

F.G. Caballero, H.K.D.H. Bhadeshia, K.J.A. Mawella, D.G. Jones, and P. Brown: Mater. Sci. Technol., 2013, vol. 18, pp. 279–84.

F.G. Caballero, C. Garcia-Mateo, and M.K. Miller: JOM, 2014, vol. 66, pp. 747–55.

B. Jiang, M. Wu, M. Zhang, F. Zhao, Z. Zhao, and Y. Liu: Mater. Sci. Eng. A, 2017, vol. 707, pp. 306–14.

M. Ou, C. Yang, J. Zhu, Q. Xia, and H. Qiao: J. Alloy Compd., 2017, vol. 697, pp. 43–54.

L. Xu, L. Chen, and W. Sun: Vacuum, 2018, vol. 154, pp. 322–32.

S.H. Kim, K.H. Kim, C.M. Bae, J.S. Lee, and D.W. Suh: Met. Mater. Int., 2018, vol. 24, pp. 693–701.

J. Zhu, Z. Zhang, and J. Xie: Mater. Sci. Eng. A, 2019, vol. 752, pp. 101–14.

J. Zhu, G.T. Lin, Z.H. Zhang, and J.X. Xie: Mater. Sci. Eng. A, 2020, vol. 797, p. 140139.

J. Zhang, Z. Dai, L. Zeng, X. Zuo, J. Wan, Y. Rong, N. Chen, J. Lu, and H. Chen: Acta Mater., 2021, vol. 217, p. 117176.

P. Wang, N. Xiao, S. Lu, D. Li, and Y. Li: Mater. Sci. Eng. A, 2013, vol. 586, pp. 292–300.

Y.Y. Song, X.Y. Li, L.J. Rong, Y.Y. Li, and T. Nagai: Mater. Chem. Phys., 2014, vol. 143, pp. 728–34.

J. Hu, L.X. Du, G.S. Sun, H. Xie, and R.D.K. Misra: Scripta Mater., 2015, vol. 104, pp. 87–90.

D. Ye, S. Li, J. Li, W. Jiang, J. Su, and K. Zhao: Mater. Charact., 2015, vol. 109, pp. 100–06.

S. Yan, X. Liu, T. Liang, and Y. Zhao: Mater. Sci. Eng. A, 2018, vol. 712, pp. 332–40.

Y.Y. Song, X.Y. Li, L.J. Rong, D.H. Ping, F.X. Yin, and Y.Y. Li: Mater. Lett., 2010, vol. 64, pp. 1411–14.

P. Song, W. Liu, C. Zhang, L. Liu, and Z. Yang: ISIJ Int., 2016, vol. 56, pp. 148–53.

A.K. da Silva, G. Inden, A. Kumar, D. Ponge, B. Gault, and D. Raabe: Acta Mater., 2018, vol. 147, pp. 165–75.

Y. Xu, W. Li, H. Du, H. Jiao, B. Liu, Y. Wu, W. Ding, Y. Luo, Y. Nie, N. Mine, W. Liu, and X. Jin: Acta Mater., 2021, vol. 214, p. 116986.

C. Wang, H. Fu, L. Jiang, D. Xue, and J. Xie: NPJ Comput. Mater., 2019, vol. 5, p. 89.

Y. Zhang, X. Gong, and H. Zhao: J. Tianjin Inst. Technol., 2003, vol. 19, pp. 69–72.

B. Zhang, F. Wang, H. Wu, and C. Li: Heat Treat. Met., 2011, vol. 36, pp. 29–33.

Y. Li, A. Nie, X. Wu, and H. Zhao: Spec. Steel, 2006, vol. 27, pp. 61–62.

H. Cai, S. Wang, W. Peng, X. Chang, and J. Ma: Heat Treat. Met., 2017, vol. 42, pp. 185–89.

Q. Li, G. Gao, L. Zhou, E. Yang, F. Chen, and J. Chen: Spec. Steel, 2012, vol. 33, pp. 49–50.

J. Zhu, M. Ou, Y. Jiang, and X. Xu: J. Mater. Sci. Eng., 2016, vol. 34, pp. 316–20.

Z. Zhang, F. Zhao, and W. Tan: Heat Treat. Met., 2014, vol. 39, pp. 104–07.

Q. Wu, L. Guo, and M. Guan: Phys. Exam. Test., 2018, vol. 36, pp. 13–16.

H. Wu, F. Wang, C. Li, and H. Cheng: Trans. Mater. Heat Treat., 2011, vol. 32, pp. 35–41.

K.M. Youssef, R.O. Scattergood, K.L. Murty, and C.C. Koch: Scripta Mater., 2006, vol. 54, pp. 251–56.

Y.H. Zhao, X.Z. Liao, Z. Jin, R.Z. Valiev, and Y.T. Zhu: Acta Mater., 2004, vol. 52, pp. 4589–99.

J. Zhu, J.X. Xie, Z.H. Zhang, and H.Y. Huang: Steel Res. Int., 2018, vol. 89, p. 1800044.

M.J. Duggin and L.J.E. Hofer: Nature, 1966, vol. 212, p. 248.

M.J. Duggin: Trans. Met. Soc. AIME, 1968, vol. 242, p. 1091.

Y. Ohmori and S. Sugisawa: Trans. Jpn Inst. Met., 1971, vol. 12, pp. 170–78.

Y. Ohmori: Trans. Jpn Inst. Met., 1972, vol. 13, pp. 119–27.

A.J. Clarke, M.K. Miller, R.D. Field, D.R. Coughlin, P.J. Gibbs, K.D. Clarke, D.J. Alexander, K.A. Powers, P.A. Papin, and G. Krauss: Acta Mater., 2014, vol. 77, pp. 17–27.

A.J. Clarke, J. Klemm-toole, K.D. Clarke, D.R. Coughlin, D.T. Pierce, V.K. Euser, J.D. Poplawsky, B. Clausen, D. Brown, J. Almer, P.J. Gibbs, D.J. Alexander, R.D. Field, D.L. Williamson, J.G. Speer, and G. Krauss: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 4984–5005.

E.I. Galindo-Nava and P.E.J. Rivera-Díaz-del-Castillo: Acta Mater., 2015, vol. 98, pp. 81–93.

H. Luo, X. Wang, Z. Liu, and Z. Yang: J. Mater. Sci. Technol., 2020, vol. 51, pp. 130–36.

S. Morito, H. Yoshida, T. Maki, and X. Huang: Mater. Sci. Eng. A, 2006, vol. 438, pp. 237–40.

J. Daigne, M. Guttman, and J.P. Naylor: Mater. Sci. Eng., 1982, vol. 56, pp. 1–10.

A. Shibata, T. Nagoshi, M. Sone, S. Morito, and Y. Higo: Mater. Sci. Eng. A, 2010, vol. 527, pp. 7538–44.

U.F. Kocks and H. Mecking: Prog. Mater. Sci., 2003, vol. 48, pp. 171–273.

B.C. De Cooman: Curr. Opin. Solid State Mater. Sci., 2004, vol. 8, pp. 285–303.

K. Zhu, C. Mager, and M. Huang: J. Mater. Sci. Technol., 2017, vol. 33, pp. 1475–86.

G. Gao, B. Gao, X. Gui, J. Hu, J. He, Z. Tan, and B. Bai: Mater. Sci. Eng. A, 2019, vol. 753, pp. 1–10.

E.J. Seo, L. Cho, and B.C. De Cooman: Acta Mater., 2016, vol. 107, pp. 354–65.

E.J. Seo, L. Cho, Y. Estrin, and B.C. De Cooman: Acta Mater., 2016, vol. 113, pp. 124–39.

K. Kim and S.J. Lee: Mater. Sci. Eng. A, 2017, vol. 698, pp. 183–90.

G.A. Thomas and J.G. Speer: Mater. Sci. Technol., 2014, vol. 30, pp. 998–1007.

G.A. Thomas, F. Danoix, J.G. Speer, S.W. Thompson, and F. Cuvilly: ISIJ Int., 2014, vol. 54, pp. 2900–06.

N. Zhong, X. Wang, Y. Rong, and L. Wang: J. Mater. Sci. Technol., 2006, vol. 22, pp. 751–54.

H.Y. Li, X.W. Lu, W.J. Li, and X.J. Jin: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 1284–1300.

D. Kim, S.-J. Lee, and B.C. De Cooman: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 4967–83.

X. Tan, Y. Xu, X. Yang, and D. Wu: Mater. Sci. Eng. A, 2014, vol. 589, pp. 101–11.

D. Kim, J.G. Speer, and B.C. De Cooman: Metall. Mater. Trans. A, 2010, vol. 42A, pp. 1575–85.

D. De Knijf, M.J. Santofimia, H. Shi, V. Bliznuk, C. Föjer, R. Petrov, and W. Xu: Acta Mater., 2015, vol. 90, pp. 161–68.

J.G. Speer, R.E. Hackenberg, B.C. De Cooman, and D.K. Matlock: Philos. Mag. Lett., 2007, vol. 7, pp. 379–82.

X. Long, F. Zhang, Z. Yang, and B. Lv: Mater. Sci. Eng. A, 2018, vol. 715, pp. 10–16.

Y.K. Kim, K.S. Kim, Y.B. Song, J.H. Park, and K.A. Lee: J. Mater. Sci. Technol., 2021, vol. 66, pp. 36–45.

C. García-Mateo and F.G. Caballero: Mater. Trans., 2005, vol. 46, pp. 1839–46.

O. Bouaziz, D. Barbier, P. Cugy, and G. Petigand: Adv. Eng. Mater., 2012, vol. 14, pp. 49–51.

H. Lee, M.C. Jo, S.S. Sohn, A. Zargaran, J.H. Ryu, N.J. Kim, and S. Lee: Acta Mater., 2018, vol. 147, pp. 247–60.

K.T. Tharian, D. Sivakumar, R. Ganesan, P. Balakrishnan, and P.P. Sinha: Mater. Sci. Technol., 1991, vol. 7, pp. 1082–88.

J.Z. Zhang, Y.G. Cui, X.W. Zuo, J. Wan, Y. Rong, N. Chen, and J. Lu: Sci. Bull., 2021, vol. 66, pp. 1058–62.

J.M. Pardal, S.S.M. Tavares, V.F. Terra, M.R. Da Silva, and D.R. Dos Santos: J. Alloy Compd., 2005, vol. 393, pp. 109–13.

U.K. Viswanathan, R. Kishore, and M.K. Asundi: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 757–61.

Acknowledgments

This research was supported by the National Natural Science Foundation (Grant Numbers 52101118 and 51925401) and Young Elite Scientists Sponsorship Program by CAST (Grant Number 2022QNRC001)

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, F., Zhang, S., Cheng, T. et al. Ultrastrong Low-Alloy Steel with Good Ductility via Multiple Strengthening, Suppressed Carbides and Reversed Austenite in Quenching and Tempering. Metall Mater Trans A (2024). https://doi.org/10.1007/s11661-024-07405-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11661-024-07405-9