Abstract

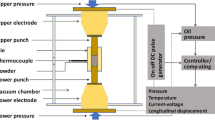

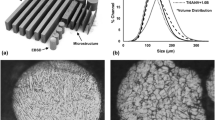

Nickel-based hardfacing alloy bushes are used in dynamic moving components inside fast breeder reactors. Due to the difficulties associated with their fabrication through casting or weld deposition, laser rapid manufacturing (LRM) was attempted. In this work, microstructure development and phase selection in laser additive manufactured Ni-based hardfacing alloy bushes are investigated. The as-fabricated bushes had a uniform, defect-free microstructure perpendicular to the material build direction, whereas microstructural heterogeneity could be detected parallel to the build direction due to coarsening of precipitates. Overall microstructure was dominated by γ-Ni, γ-Ni + Ni3B anomalous and lamellar eutectic and Ni–B–Si lamellar eutectic constituents. In addition, Cr-rich borides and carbides were also found. Phase property diagrams and Scheil’s non-equilibrium solidification simulated using ThermoCalc® provided supporting insights into the phase selection phenomena under rapid cooling conditions. Microstructure of LRM Ni-based hardfacing alloy bushes was quite distinct from weld deposited ones and is analyzed in terms of a non-equilibrium eutectic solidification reaction occurring in Ni–Cr–B–C–Si–Fe multicomponent alloy system due to rapid cooling.

Similar content being viewed by others

References

A.K. Bhaduri, R. Indira, S.K. Albert, B.P.C. Rao, S.C. Jain, and S. Ashok Kumar: J. Nucl. Mater., 2004, vol. 334, pp. 109–14. https://doi.org/10.1016/j.jnucmat.2004.05.005.

S. Balaguru and M. Gupta: J. Mater. Res. Technol., 2021, vol. 10, pp. 1210–42. https://doi.org/10.1016/j.jmrt.2020.12.026.

ASM International: ASM Metals Handbook, vol. 6, 9th ed., ASM International, Materials Park, OH, USA, 1993, pp. 794–95.

M. Corchia, P. Delogu, F. Nenci, A. Belmondo, S. Corcoruto, and W. Stabielli: Wear, 1987, vol. 119, pp. 137–52. https://doi.org/10.1016/0043-1648(87)90105-0.

T. Liyanage, G. Fisher, and A.P. Gerlich: Surf. Coat. Technol., 2010, vol. 205, pp. 759–65. https://doi.org/10.1016/j.surfcoat.2010.07.095.

R. Kaul, P. Ganesh, S.K. Albert, A. Jaiswal, N.P. Lalla, A. Gupta, C.P. Paul, and A.K. Nath: Surf. Eng., 2003, vol. 19, pp. 269–73. https://doi.org/10.1179/026708403322499182.

Q. Ming, L.C. Lim, and Z.D. Chen: Surf. Coat. Technol., 1998, vol. 106, pp. 183–92. https://doi.org/10.1016/S0257-8972(98)00525-8.

S. Gnanasekaran, G. Padmanaban, V. Balasubramanian, H. Kumar, and S.K. Albert: High Temp. Mater. Process., 2019, vol. 38, pp. 16–29. https://doi.org/10.1515/htmp-2017-0176.

I. Hemmati, V. Ocelík, K. Csach, and J.T.M. De Hosson: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 878–92. https://doi.org/10.1007/s11661-013-2004-4.

G. Xu, M. Kutsuna, Z. Liu, and H. Zhang: Mater. Sci. Eng. A, 2006, vol. 417, pp. 63–72. https://doi.org/10.1016/j.msea.2005.08.192.

R. González, M.A. García, I. Penuelas, M. Cadenas, M. del Rocío Fernández, A.H. Battez, and D. Felgueroso: Wear, 2007, vol. 263, pp. 619–24. https://doi.org/10.1016/j.wear.2007.01.094.

Q. Li, D. Zhang, T. Lei, C. Chen, and W. Chen: Surf. Coat. Technol., 2001, vol. 137, pp. 122–35. https://doi.org/10.1016/S0257-8972(00)00732-5.

L.J. da Silva, C.J. Scheuer, and A.S.C.M. D’Oliveira: Wear, 2019, vol. 428–29, pp. 387–94. https://doi.org/10.1016/j.wear.2019.04.005.

I. Hemmati, J.C. Rao, V. Ocelík, and J.T.M. De Hosson: Microsc. Microanal., 2013, vol. 19, pp. 120–31. https://doi.org/10.1017/S1431927612013839.

K.F. Tam, F.T. Cheng, and H.C. Man: Surf. Coat. Technol., 2002, vol. 149, pp. 36–44. https://doi.org/10.1016/S0257-8972(01)01414-1.

I. Hemmati, V. Ocelík, and J.T.M. De Hosson: Phys. Procedia, 2013, vol. 41, pp. 302–11. https://doi.org/10.1016/j.phpro.2013.03.082.

J.C. Pereira, M.C. Taboada, A. Niklas, E. Rayón, and J. Rocchi: J. Manuf. Mater. Process., 2023, vol. 7, pp. 110–30. https://doi.org/10.3390/jmmp7030110.

H.J. Kim and Y.J. Kim: Surf. Eng., 1999, vol. 15, pp. 495–501. https://doi.org/10.1179/026708499101516911.

S. Lebaili, M. Durand-Charre, and S. Hamar-Thibault: J. Mater. Sci., 1988, vol. 23, pp. 3603–11. https://doi.org/10.1007/BF00540502.

G. Chakraborty, R. Rani, R. Ramaseshan, M.A. Davinci, C.R. Das, T. Mathews, and S.K. Albert: Tribol. Trans., 2021, vol. 64, pp. 658–66. https://doi.org/10.1080/10402004.2021.1896059.

V. Ramasubbu, G. Chakraborty, S.K. Albert, and A.K. Bhaduri: Mater. Sci. Technol., 2009, vol. 27, pp. 573–80. https://doi.org/10.1179/026708309X12526555493431.

C.R. Das, S.K. Albert, A.K. Bhaduri, and R. Nithya: Mater. Sci. Technol., 2007, vol. 23, pp. 771–79. https://doi.org/10.1179/174328407X185802.

G. Chakraborty, N. Kumar, C.R. Das, S.K. Albert, A.K. Bhaduri, S. Dash, and A.K. Tyagi: Surf. Coat. Technol., 2014, vol. 244, pp. 180–88. https://doi.org/10.1016/j.surfcoat.2014.02.013.

P.R. Reinaldo and A.S.C.M. D’Oliveira: J. Mater. Eng. Perform., 2013, vol. 22, pp. 590–97. https://doi.org/10.1007/s11665-012-0271-7.

C. Sudha, P. Shankar, R.V. Subba Rao, R. Thirumurugesan, M. Vijayalakshmi, and B. Raj: Surf. Coat. Technol., 2008, vol. 202, pp. 2103–12. https://doi.org/10.1016/j.surfcoat.2007.08.063.

G. Chakraborty, S.K. Albert, and A.K. Bhaduri: Mater. Sci. Technol., 2012, vol. 28, pp. 454–59. https://doi.org/10.1179/1743284711Y.0000000082.

L.J. da Silva and A.S.C.M. D’Oliveira: Wear, 2016, vol. 350–51, pp. 130–40. https://doi.org/10.1016/j.wear.2016.01.015.

S. Balaguru, V. Murali, P. Chellapandi, and M. Gupta: Nucl. Eng. Technol., 2020, vol. 52, pp. 589–96. https://doi.org/10.1016/j.net.2019.08.011.

C.R. Das, S.K. Albert, A.K. Bhaduri, and G. Kempulraj: J. Mater. Process. Technol., 2003, vol. 141, pp. 60–66. https://doi.org/10.1016/S0924-0136(02)01130-5.

C.P. Paul, A. Jain, P. Ganesh, J. Negi, and A.K. Nath: Opt. Lasers Eng., 2006, vol. 44, pp. 1096–1109. https://doi.org/10.1016/j.optlaseng.2005.08.005.

ICDD database, https://www.icdd.com. Accessed 2 June 2022.

S. Ômori, Y. Hashimoto, S. Nakamura, K. Hidaka, and Y. Kohira: J. Jpn. Soc. Powder Metall., 1971, vol. 18, pp. 132–35. https://doi.org/10.2497/jjspm.18.132.

K.L. Fraga-Chávez, M.J. Castro-Román, M. Herrera-Trejo, L.E. Ramírez-Vidaurri, and I. Aguilera-Luna: Metals, 2017, vol. 7, pp. 187–202. https://doi.org/10.3390/met7060187.

T.A.M. Haemers, D.G. Rickerby, F. Lanza, F. Geiger, and E.J. Mittemeijer: J. Mater. Sci., 2000, vol. 35, pp. 5691–98. https://doi.org/10.1023/A:1004858508274.

J. Ajao and S. Hamar Thibault: J. Mater. Sci., 1988, vol. 23, pp. 1112–25. https://doi.org/10.1007/BF01154022.

L.Y. Chen, T. Xu, H. Wang, P. Sang, S. Lu, Z.X. Wang, S. Chen, and L.C. Zhang: Surf. Coat. Technol., 2019, vol. 358, pp. 467–80. https://doi.org/10.1016/j.surfcoat.2018.11.019.

A. Prince: Alloy Phase Equilibria, Elsevier Publications, New York, 1966, pp. 173–98.

L.Y. Chen, H. Wang, C. Zhao, S. Lu, Z.X. Wang, J. Sha, S. Chen, and L.C. Zhang: Surf. Coat. Technol., 2019, vol. 369, pp. 31–43. https://doi.org/10.1016/j.surfcoat.2019.04.052.

E.E. Kornienko, A.A. Nikulina, A.G. Bannov, and A.S. Ivashutenko: Met. Sci. Heat Treat., 2022, vol. 63, pp. 637–43. https://doi.org/10.1007/s11041-022-00742-9.

Acknowledgments

Authors gratefully acknowledge Dr. S. Raju, former Director MMG; Dr. John Philip, Associate Director MMG; Dr. R. Divakar, Director MMG; and Dr. B. Venkatraman, Director IGCAR for their constant support and encouragement during the course of this work.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Haribabu, S., Sudha, C., Paul, C.P. et al. Phase Selection and Microstructure Evolution in Laser Additive Manufactured Ni-Based Hardfacing Alloy Bush. Metall Mater Trans A 55, 218–231 (2024). https://doi.org/10.1007/s11661-023-07244-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07244-0