Abstract

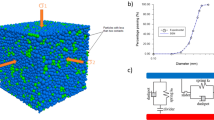

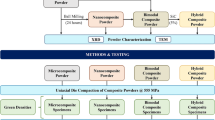

Nowadays, experimental and simulation investigations are of importance in industrial design. The influence of volume fractions and boundary conditions on the effective properties of Al/Ni composites is studied in this paper. The composites with modified microstructure were manufactured through a roll bonding process. The microstructural characterizations showed that the elliptical Ni fragments were uniformly distributed within the matrix. Furthermore, the perfect bonding of layers without cracks and voids was achieved. Also, despite the reduction in elongation, with an increase in the volume fraction of Ni, there was an improvement in the elastic modulus, yield, and ultimate strengths of composites. Next, a series of computational experiments were carried out to estimate the elastic properties of composites by using both microstructure-based and artificial RVEs subjected to linear displacement boundary condition (LDBC) and periodic displacement boundary condition (PDBC). The random sequential adsorption (RSA) method was used to automatically generate the artificial RVEs in which the Ni fragments were randomly distributed and were not overlapped. However, the most striking result to emerge from the finite element analysis is that both RVEs could give a successful prediction of the actual macroscopic behavior of the composite. Furthermore, the predicted results of both LDBC and PDBC were relatively similar to the experimentally-obtained ones.

Similar content being viewed by others

References

A.H. Assari: J. Manuf. Process., 2023, vol. 95, pp. 369–81.

J. Luo, R. Khattinejad, A. Assari, M. Tayyebi, and B. Hamawandi: Crystals, 2023, vol. 13, p. 354.

G.-Z. Ma, P.-F. He, H.-D. Wang, H.-G. Tian, Li. Zhou, Q.-S. Yong, M. Liu, H.-C. Zhao, and D.-y He: Mater. Des., 2023, vol. 227, p. 111764.

Z.Y. Zhu, Y.L. Liu, G.Q. Gou, W. Gao, and J. Chen: Sci. Rep., 2021, vol. 11, p. 10020.

G. Feng, Hu. Bingxu, Y. Wei, Hu. Tao, Z. Li, P. He, Y. Wang, D. Deng, and X. Yang: J. Market. Res., 2022, vol. 19, pp. 3994–4002.

H. Deng, Y. Chen, Y. Jia, Y. Pang, T. Zhang, S. Wang, and L. Yin: J. Manuf. Process., 2021, vol. 64, pp. 379–91.

X. Tian, Y. Zhao, Gu. Tao, Y. Guo, Xu. Fengqiang, and H. Hou: Mater. Sci. Eng., A, 2022, vol. 849, p. 143485.

J. Wang, Z. Pan, Y. Wang, L. Wang, Su. Lihong, D. Cuiuri, Y. Zhao, and H. Li: Addit. Manuf., 2020, vol. 34, p. 101240.

H. Zhang, Y. Xiao, Xu. Ziqi, M. Yang, L. Zhang, L. Yin, S. Chai, G. Wang, L. Zhang, and X. Cai: Intermetallics, 2022, vol. 150, p. 107683.

L. Shevtsova, V. Mali, A. Bataev, A. Anisimov, and D. Dudina: Mater. Sci. Eng. A, 2020, vol. 773, p. 138882.

J. Liang, Ye. Liu, S. Yang, X. Yin, S. Chen, and C. Liu: Surf. Coat. Technol., 2022, vol. 445, p. 128727.

C.S. Kumar, D. Yadav, R. Bauri, and G.J. Ram: Mater. Sci. Eng. A, 2015, vol. 645, pp. 205–12.

T.K. Akopyan, A.S. Aleshchenko, N.A. Belov, and S.P. Galkin: Phys. Met. Metall., 2018, vol. 119, pp. 241–50.

J. Liu, Wu. Yuze, H. Gao, C. Kong, and Yu. Hailiang: Metall. Mater. Trans. A, 2023, vol. 54, pp. 16–22.

N.M. Anas, B.K. Dhindaw, H. Zuhailawati, T.K. Abdullah, and A.S. Anasyida: J. Mater. Eng. Perform., 2018, vol. 27, pp. 6206–217.

M. Naderi, M. Peterlechner, S.V. Divinski, and G. Wilde: Mater. Sci. Eng. A, 2017, vol. 708, pp. 171–80.

Y. Yan, Y. Qi, Q.-W. Jiang, and X.-W. Li: Acta Metall. Sin. (Eng. Lett.), 2015, vol. 28, pp. 531–41.

S.A. Zakaria, A.S. Anasyida, H. Zuhailawati, B.K. Dhindaw, N.A. Jabit, and A. Ismail: Trans. Nonferrous Met. Soc. China, 2021, vol. 31, pp. 2949–61.

A.P. Zhilyaev, M.J. Torres, H.D. Cadena, S.L. Rodriguez, J. Calvo, and J.M. Cabrera: Materials, 2020, vol. 13, p. 2361.

K. Chandra Sekhar, R. Narayanasamy, and K. Velmanirajan: Mater. Design, 2014, vol. 53, pp. 1064–70.

V. Turlo and T.J. Rupert: Acta Mater., 2018, vol. 151, pp. 100–1.

S.E. Ahmed, W. Al-Kouz, and A.M. Aly: ZAMM J. Appl. Math. Mech., 2023, vol. 103, p. e202100329.

J. Baili, A. Raza, M. Azab, K. Ali, M.H. El Ouni, H. Haider, and M.A. Farooq: Mech. Adv. Mater. Struct., 2023, vol. 30, pp. 4913–32.

M. Berradia, M. Azab, Z. Ahmad, O. Accouche, A. Raza, and Y. Alashker: Struct. Eng. Mech., 2022, vol. 83, pp. 515–35.

M. Moustafa, G. Laouini, and T. Alzoubi: Arch. Acoust. 2021, pp. 419-26-19-26.

G. Yan, A. Shawabkeh, R. Chaturvedi, R. Nur-Firyal, and M.M. Youshanlouei: Case Stud. Thermal Engi., 2022, vol. 36, p. 102153.

N. El Hassan, K. Jabbour, A.H. Fakeeha, Y. Nasr, M.A. Naeem, S.B. Alreshaidan, and A.S. Al-Fatesh: Alex. Eng. J., 2023, vol. 63, pp. 143–55.

M.K. Hassanzadeh-Aghdam and J. Jamali: Proc. Inst. Mech. Eng. Part C, 2022, vol. 236, pp. 8012–26.

S.K. Mert, M. Demiral, M. Altin, E. Acar, and M.A. Güler: J. Braz. Soc. Mech. Sci. Eng., 2021, vol. 43, pp. 1–22.

M.T. Nasri, F. Abbassi, F. Ahmad, W. Makhloufi, M. Ayadi, H. Mehboob, and H.S. Choi: Mech. Adv. Mater. Struct., 2023, vol. 30, pp. 2087–100.

M. Sherri, I. Boulkaibet, T. Marwala, and M.I. Friswell: In Model Validation and Uncertainty Quantification, Volume 3: Proceedings of the 39th IMAC, A Conference and Exposition on Structural Dynamics 2021, Springer: 2022, pp 163–74.

Y. Zhao: Npj Comput. Mater., 2023, vol. 9, p. 94.

S. Bargmann, B. Klusemann, J. Markmann, J.E. Schnabel, K. Schneider, C. Soyarslan, and J. Wilmers: Prog. Mater. Sci., 2018, vol. 96, pp. 322–84.

A. El Moumen, T. Kanit, A. Imad, and H. El Minor: Mech. Mater., 2015, vol. 83, pp. 1–6.

I.M. Gitman, H. Askes, and L.J. Sluys: Eng. Fract. Mech., 2007, vol. 74, pp. 2518–34.

D. Horny and K. Schulz: J. Mater. Sci., 2022, vol. 57, pp. 8869–889.

E. Hannachi, K.G. Mahmoud, Y. Slimani, M.I. Sayyed, J. Arayro, and Y. Maghrbi: Crystals, 2023, vol. 13, p. 230.

J. Fang, Y. Quan, and B. Dong: Int. J. Heat Mass Transf., 2023, vol. 208, p. 124084.

M. Haghgoo, R. Ansari, and M.K. Hassanzadeh-Aghdam: J. Phys. Chem. Solids, 2022, vol. 161, p. 110444.

L. Chen, Gu. Boqin, J. Tao, and J. Zhou: Compos. Struct., 2019, vol. 216, pp. 279–89.

E. Acar, E.E. Üstün, M.A. Güler, A. Toros, and O. Müştak: Mechanics Based Design of Structures and Machines 2022, pp. 1-22.

F. Ahmad, H. Mehboob, F. Abbassi, J.-W. Hong, J. Zghal, and A. Mehboob: Mech. Adv. Mater. Struct., 2022, vol. 29, pp. 4457–467.

S. Ghouli, M.R. Ayatollahi, B. Bahrami, and J. Jamali: Theor. Appl. Fract. Mech., 2022, vol. 118, p. 103211.

A. Herez, H. Jaber, H. El Hage, T. Lemenand, K. Chahine, M. Ramadan, and M. Khaled: Int. J. Thermofluids, 2023, vol. 17, p. 100309.

M.A. Kouka, F. Abbassi, M. Demiral, F. Ahmad, M. Soula, and F. Al Housni: Eng. Fract. Mech., 2021, vol. 251, p. 107802.

A. Denisiewicz, M. Kuczma, K. Kula, and T. Socha: Materials, 2021, vol. 14, p. 1009.

H. Qing: Mater. Des., 2013, vol. 44, pp. 446–53.

M.M. Shahzamanian, S.S. Akhtar, A.F. Arif, W.J. Basirun, K.S. Al-Athel, M. Schneider, N. Shakelly, A.S. Hakeem, A.A. Abubakar, and P. Wu: Sci. Rep., 2022, vol. 12, p. 11076.

H.M. Inglis, P.H. Geubelle, and K. Matouš: Philos. Mag., 2008, vol. 88, pp. 2373–97.

H. Wei, D. Lyu, W. Hu, and C.T. Wu: arXiv preprint arXiv:2210.11761 2022.

F. Otero, S. Oller, and X. Martinez: Arch. Comput. Methods Eng., 2018, vol. 25, pp. 479–505.

Indra Vir Singh, AS Shedbale, and BK Mishra: Journal of composite materials 2016, vol. 50, pp. 2757-71.

T. Inoue, A. Yanagida, and J. Yanagimoto: Mater. Lett., 2013, vol. 106, pp. 37–40.

D.C. Magalhães, O.M. Cintho, J.B. Rubert, V.L. Sordi, and A.M. Kliauga: Mater. Sci. Eng. A, 2020, vol. 796, p. 140055.

K. Verstraete, A.L. Helbert, F. Brisset, and T. Baudin: In IOP Conference Series: Materials Science and Engineering, IOP Publishing: 2014, p 012090.

S.H. Lee, Y. Saito, N. Tsuji, H. Utsunomiya, and T. Sakai: Scripta Mater., 2002, vol. 46, pp. 281–85.

K. Brunelli, L. Peruzzo, and M. Dabalà: Mater. Chem. Phys., 2015, vol. 149, pp. 350–58.

X. Guo, Y. Ma, K. Jin, H. Wang, J. Tao, and M. Fan: J. Mater. Eng. Perform., 2017, vol. 26, pp. 4235–244.

G. Min, J.-M. Lee, S.-B. Kang, and H.-W. Kim: Mater. Lett., 2006, vol. 60, pp. 3255–59.

H. Wang, Lu. Cheng, K. Tieu, G. Deng, P. Wei, and Yu. Liu: Sci. Rep., 2019, vol. 9, p. 3401.

G.V. Jagadeesh and S.G. Setti: J. Mater. Sci., 2020, vol. 55, pp. 9848–82.

Izabela B, Andrzej T, Michaà T, and Piotr B: Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2011, vol. 73, pp. 192-98.

S. Ma, X. Zhang, T. Chen, and X. Wang: Mater. Des., 2020, vol. 191, p. 108685.

M. Kathiresan, K. Manisekar, V. Rajamohan, and M.A. Güler: Mech. Adv. Mater. Struct., 2022, vol. 29, pp. 5360–77.

J.M. Tyrus, M. Gosz, and E. DeSantiago: Int. J. Solids Struct., 2007, vol. 44, pp. 2972–989.

A. Raza, M. Azab, Z.A. Baki, C. El Hachem, M.H. El Ouni, and N.B. Kahla: Alex. Eng. J., 2023, vol. 64, pp. 451–63.

A. Mamedov: J. Mech. Sci. Technol., 2021, vol. 35, pp. 4143–148.

M.Z. Dehaghani, A. Salmankhani, A.H. Mashhadzadeh, S. Habibzadeh, O. Abida, and M.R. Saeb: Eng. Fract. Mech., 2021, vol. 244, p. 107552.

C. Miehe and A. Koch: Arch. Appl. Mech., 2002, vol. 72, pp. 300–17.

Data Availability

The raw/processed data required to reproduce these findings cannot be fully shared at this time due to technical or time limitations.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants performed by any of the authors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuanwu, S., Assari, A.H., Yaghoobi, S. et al. Influence of Volume Fractions and Boundary Conditions on the Predicted Effective Properties of Al/Ni Composites for Industrial Design. Metall Mater Trans A 55, 118–133 (2024). https://doi.org/10.1007/s11661-023-07231-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07231-5