Abstract

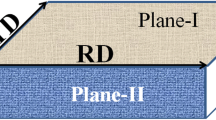

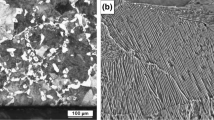

The three-dimensional lamellar alignment of pearlitic steels pre-processed with cold rolling and drawing before the pearlitic transformation was quantitatively evaluated using a semi-automatic habit plane analysis. The analysis was successfully conducted, although the habit planes were dispersed depending on the geometry of the specimen owing to the cementite (Fe3C) plates interrupting the incident electron beam to the ferrite (α) phase during the electron backscattered diffraction analysis. Pitsch–Petch and Isaichev orientation relationships between α and Fe3C were detected within one block. The block and colony sizes and lamellar spacing were insignificantly changed by pre-processing, however, the α phase texture was differed according to the pre-processing conditions. The rolling texture in the cold-rolled specimen inherited even after heat-treatment. The non-pre-processed specimen exhibited a random lamellar alignment distribution, whereas specific lamellar alignments were accumulated in the pre-processed specimens, strongly suggesting that pre-processing affected the lamellar alignment. The number of colonies in the pre-processed specimens with a lamellar alignment (normal of habit plane) perpendicular to the stress axis during pre-processing tended to be small. The lamellar alignment tended to fit that expected from the texture in pre-processed specimens. The texture and residual stress developed during pre-processing may affect the lamellar alignment in pearlitic steels.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

I.V. Isaichev: Zh. Tekh. Fiz., 1947, vol. 17, pp. 835–38.

N.J. Petch: Acta Crystallogr., 1953, vol. 6, p. 96. https://doi.org/10.1107/S0365110X53000260.

W. Pitsch: Acta Metall., 1962, vol. 10, pp. 79–80. https://doi.org/10.1016/0001-6160(62)90190-6.

Y.A. Bagaryatsky: Dokl. Akad. Nauk SSSR, 1947, vol. 73, pp. 1161–64.

A. Durgaprasad, S. Giri, S. Lenka, S. Kundu, S. Mishra, S. Chandra, R.D. Doherty, and I. Samajdar: Acta Mater., 2017, vol. 129, pp. 278–89. https://doi.org/10.1016/j.actamat.2017.02.008.

T. Takahashi, M. Nagumo, and Y. Asano: J. Japan Inst., 1978, vol. 42, pp. 716–23. https://doi.org/10.2320/jinstmet1952.42.7_716.

A. Walentek, M. Seefeldt, B. Verlinden, E. Aernoudt, and P.V. Houtte: J. Microsc., 2006, vol. 224, pp. 256–63. https://doi.org/10.1111/j.1365-2818.2006.01702.x.

A. Walentek, M. Seefeldt, B. Verlinden, E. Aernoudt, and P.V. Houtte: Mater. Sci. Eng. A, 2008, vol. 483–484, pp. 716–18. https://doi.org/10.1016/j.msea.2006.12.171.

S. Zaefferer, S.I. Wrightm, and D. Raabe: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 374–89. https://doi.org/10.1007/s11661-007-9418-9.

T. Takahashi, D. Ponge, and D. Raabe: Steel Res. Int., 2007, vol. 78, pp. 38–44. https://doi.org/10.1002/srin.200705857.

B. Karlsson and G. Lindén: Mater. Sci. Eng., 1975, vol. 17, pp. 153–64. https://doi.org/10.1016/0025-5416(75)90039-7.

J.M. Hyzak and I.M. Bernstein: Metal. Trans. A, 1976, vol. 7, pp. 1217–24. https://doi.org/10.1007/BF02656606.

A.M. Elwazri, P. Wanjara, and S. Yue: Mater. Sci. Eng. A, 2005, vol. 404, pp. 91–98. https://doi.org/10.1016/j.msea.2005.05.051.

A.R. Marder and B.L. Bramfitt: Metal. Trans. A, 1976, vol. 7, pp. 365–72. https://doi.org/10.1007/BF02642832.

N. Nakada, N. Koga, Y. Tanaka, T. Tsuchiyama, S. Takaki, and M. Ueda: ISIJ Int., 2015, vol. 55, pp. 2036–38. https://doi.org/10.2355/isijinternational.ISIJINT-2015-102.

Y. Ohmori, A.T. Davenport, and R.W.K. Honeycombet: Trans. ISIJ, 1972, vol. 12, pp. 128–37. https://doi.org/10.2355/isijinternational1966.12.128.

G. Langford: Metal. Trans. A, 1977, vol. 8, pp. 861–75. https://doi.org/10.1007/BF02661567.

Y. Adachi, S. Morooka, K. Nakajima, and Y. Sugimoto: Acta Mater., 2008, vol. 58, pp. 5995–6002.

T. Teshima, M. Kosaka, K. Ushioda, N. Koga, and N. Nakada: Mater. Sci. Eng. A, 2017, vol. 679, pp. 223–29. https://doi.org/10.1016/j.msea.2016.10.018.

Y. Yajima, N. Koga, and C. Watanabe: Mater Charact, 2021, vol. 177, 111197https://doi.org/10.1016/j.matchar.2021.111197.

N. Nakada, N. Koga, T. Tsuchiyama, and S. Takaki: Scr. Mater., 2009, vol. 64, pp. 133–36. https://doi.org/10.1016/j.scriptamat.2009.03.028.

N. Koga, N. Nakada, T. Tsuchiyama, S. Takaki, M. Ojima, and Y. Adachi: Scr. Mater., 2012, vol. 67, pp. 400–03. https://doi.org/10.1016/j.scriptamat.2015.05.034.

S. Endo, N. Miyazawa, N. Nakada, S. Onaka, T. Teshima, and M. Kosaka: ISIJ Int., 2022, vol. 62, pp. 291–98. https://doi.org/10.2355/isijinternational.ISIJINT-2021-332.

J.D. Embury and R.M. Fisher: Acta Metall., 1966, vol. 14, pp. 147–59. https://doi.org/10.1016/0001-6160(66)90296-3.

D. Wei, X. Min, Z. Xie, and F. Fang: Mater. Sci. Eng. A, 2020, vol. 784, 139341https://doi.org/10.1016/j.msea.2020.139341.

S. Narayanswamy, R. Saha, and P.P. Bhattacharjee: Mater. Char., 2021, vol. 171, 110751https://doi.org/10.1016/j.matchar.2020.110751.

H. Tashiro and H. Sato: J. Jpn. Inst. Met., 1991, vol. 55, pp. 1078–85. https://doi.org/10.2320/jinstmet1952.55.10_1078.

M. Hölscher, D. Raabe, and K. Lücke: Steel Res., 1991, vol. 62, pp. 567–75. https://doi.org/10.1002/srin.199100451.

M.R. Barnett and J.J. Jonas: ISIJ Int., 1997, vol. 37, pp. 706–14. https://doi.org/10.2355/isijinternational.37.706.

F. Fang, Y. Zhao, L. Zhou, X. Hu, Z. Xie, and J. Jiang: Mater. Sci. Eng. A, 2014, vol. 618, pp. 505–10. https://doi.org/10.1016/j.msea.2014.09.061.

R.J. Dippenaar and R.W.K. Honeycombe: Proc. R. Soc. Lond. A, 1973, vol. 333, pp. 455–67. https://doi.org/10.1098/rspa.1973.0073.

D.S. Zhou and G.J. Shiflet: Metall. Trans. A, 1992, vol. 23, pp. 1259–69. https://doi.org/10.1007/BF02665057.

N. Gey, B. Petit, and M. Humbert: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 3291–99. https://doi.org/10.1007/s11661-005-0003-9.

G. Miyamoto, N. Iwata, N. Takayama, and T. Furuhara: J. Alloys Compds., 2013, vol. 577, pp. S528-532. https://doi.org/10.1016/j.jallcom.2011.12.111.

Y. Matsuoka, T. Iwasaki, N. Nakada, T. Tsuchiyama, and S. Takaki: ISIJ Int., 2013, vol. 53, pp. 1224–30. https://doi.org/10.2355/isijinternational.53.1224.

Acknowledgments

This work was supported by JKA and its promotion funds from KEIRIN RACE. The authors also acknowledge the financial support of the Grant-in-Aid for Scientific Research (KAKENHI) Grant No. 23K17815.

Author information

Authors and Affiliations

Contributions

NK: Investigation, Visualization, Data curation, Writing-original draft, Formal analysis, Writing – review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The author declare no conflict of interest.

Ethical Approval

No human tissues were involved in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Koga, N. Quantitative Analysis of Three-Dimensional Lamellar Alignment in Pearlitic Steel With Various Pre-processing Using Semi-automatic Habit Plane Analysis. Metall Mater Trans A 54, 4966–4975 (2023). https://doi.org/10.1007/s11661-023-07217-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07217-3