Abstract

To overcome the trade-off between strength and ductility, a low-cost method comprising room-temperature compression followed by artificial aging and compressive deformation was applied to a commercial AZ61 alloy. The goal of this work was to regulate the microstructure rather than refine the grains. For this purpose, fragmented precipitates decorating the boundaries of narrow twins and stable networks developed by two non-basal slip systems were achieved. With this novel microstructure, a highly improved yield strength of almost 120 MPa was realized with slightly decreased ductility. It is believed that this provides a novel orientation for rationally designing strength and ductility in age-hardenable Mg alloys by tailoring the precipitate scale and dislocation configuration.

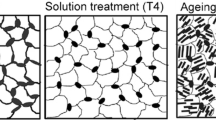

Graphical Abstract

Similar content being viewed by others

References

H. Ovri, J. Markmann, J. Barthel, M. Kruth, H. Dieringa, and E.T. Lilleodden: Acta Mater., 2023, vol. 244, p. 118550.

Z. Zhang, Q. Huo, Z. Xiao, A. Hashimoto, and X. Yang: Mater. Sci. Eng. A, 2020, vol. 772, p. 138816.

J.U. Lee, S. Kim, Y.J. Kim, and S.H. Park: Mater. Sci. Eng. A, 2018, vol. 714, pp. 49–58.

X.F. Niu, G. Li, Z.Y. Zhang, P.W. Zhou, H.X. Wang, S.X. Zhang, and W.L. Cheng: Mater. Sci. Eng. A, 2019, vol. 743, pp. 207–16.

Z. Zhang, Q. Huo, Z. Xiao, Y. Zhang, A. Hashimoto, and X. Yang: Mater. Sci. Eng. A, 2021, vol. 812, p. 141102.

S. Hu, Q. Huo, C. Wang, Y. Zhang, Z. Zhang, S. Xu, and X. Yang: J. Alloys Compd., 2022, vol. 895, p. 162666.

C. Chen, D.S. Han, M.C. Wang, S. Xu, T. Cai, S. Yang, F.J. Shi, B. Beausir, and L.S. Toth: J. Alloys Compd., 2023, vol. 931, p. 167498.

C.J. Yan, Y.C. Xin, X.B. Chen, D.K. Xu, P.K. Chu, C.Q. Liu, B. Guan, X.X. Huang, and Q. Liu: Nat. Commun., 2021, vol. 12, p. 4616.

Y.H. Li, Y.Q. Jiang, Q. Xu, A.B. Ma, J.H. Jiang, H. Liu, Y.C. Yuan, and C. Qiu: Mater. Sci. Eng. A, 2021, vol. 804, p. 140717.

L. Luo, Z.Y. Xiao, Q.H. Huo, Y. Yang, W.Y. Huang, J.C. Guo, Y.X. Ye, and X.Y. Yang: J. Alloys Compd., 2018, vol. 740, pp. 180–93.

F.Y. Liu, R.L. Xin, C.P. Wang, B. Song, and Q. Liu: Scr. Mater., 2019, vol. 158, pp. 131–35.

Y.S. Liu, J.W. Yan, D.Y. Xie, Y. Shen, J. Wang, and G.Z. Zhu: Scr. Mater., 2021, vol. 191, pp. 86–89.

J. Li, J.L. Wu, L. Jin, M. Celikin, F.H. Wang, S. Dong, and J. Dong: Sci. Rep., 2021, vol. 11, p. 2860.

A.H. Blake and C.H. Cáceres: Mater. Sci. Eng. A, 2008, vol. 483–484, pp. 161–63.

D.X. Zhao, X.L. Ma, A. Srivastava, G. Turner, I. Karaman, and K.Y. Xie: Acta Mater., 2021, vol. 207, p. 116691.

S. Si, J. Wu, I.P. Jones, and Y.L. Chiu: Philos. Mag., 2020, vol. 100, pp. 2949–71.

Q. Huo, Z. Xiao, X. Yang, D. Ando, Y. Sutou, and J. Koike: Mater. Sci. Eng. A, 2017, vol. 696, pp. 52–59.

J.F. Nie: Scr. Mater., 2003, vol. 48, pp. 1009–015.

N. Tahreen, D.L. Chen, M. Nouri, and D.Y. Li: J. Alloys Compd., 2015, vol. 623, pp. 15–23.

J. Jain, W.J. Poole, C.W. Sinclair, and M.A. Gharghouri: Scr. Mater., 2010, vol. 62, pp. 301–04.

M.H. Yoo: Metall. Trans. A, 1981, vol. 12A, p. 401.

A.H. Cottrell and B.A. Bilby: Philos. Mag., 1951, vol. 42, p. 573.

M.A. Gharghouri, G.C. Weatherly, and J.D. Embury: Philos. Mag. A, 1998, vol. 78, pp. 1137–149.

T. Chen, S. Hu, S. Li, and Q. Huo: Mater. Sci. Eng. A, 2022, vol. 857, p. 144056.

S. Kim, J.U. Lee, Y.J. Kim, J.H. Bae, B.S. You, and S.H. Park: J. Mater. Sci. Technol., 2018, vol. 34, pp. 265–76.

N. Li, C. Wang, M.A. Monclús, L. Yang, and J.M. Molina-Aldareguia: Acta Mater., 2021, vol. 221, p. 117374.

Z. Yan, Q. Yang, F. Meng, R. Ma, R. Bao, X. Liu, J. Meng, and X. Qiu: J. Mater. Sci. Technol., 2021, vol. 93, pp. 103–09.

K. Yaddanapudi, B. Leu, M.A. Kumar, X. Wang, J.M. Schoenung, E.J. Lavernia, T.J. Rupert, I.J. Beyerlein, and S. Mahajan: Acta Mater., 2021, vol. 204, p. 116514.

S.R. Kada, P.A. Lynch, J.A. Kimpton, and M.R. Barnett: Acta Mater., 2016, vol. 119, pp. 145–56.

Y. Zhang, T. Chen, J. Kuang, and Q. Huo: Metall. Mater. Trans. A, 2022, vol. 53A, pp. 747–53.

X. Wang, M. Jahazi, and S. Yue: Mater. Sci. Eng. A, 2006, vol. 434, pp. 188–93.

G.Z. Kang, Y.W. Dong, Y.J. Liu, and H. Jiang: Mater. Charact., 2014, vol. 92, pp. 26–35.

P.O. Tympel, T.C. Lindley, E.A. Saunders, M. Dixon, and D. Dye: Acta Mater., 2016, vol. 103, pp. 77–88.

J.S. Jha, S. Dhala, S.P. Toppo, R. Singh, A. Tewari, S.K. Mishra, and B. Jayabalan: Mater. Charact., 2019, vol. 155, p. 109829.

A. Jain, O. Duygulu, D.W. Brown, C.N. Tomé, and S.R. Agnew: Mater. Sci. Eng. A, 2008, vol. 486, pp. 545–55.

M. Sabbaghian, R. Mahmudi, and K.S. Shin: Mater. Sci. Eng. A, 2022, vol. 845, p. 143218.

U.M. Chaudry, Y. Noh, G. Han, R. Jaafreh, T. Jun, and K. Hamad: Mater. Sci. Eng. A, 2022, vol. 844, p. 143189.

T. Nakata, C. Xu, L. Geng, and S. Kamado: J. Alloys Compd., 2022, vol. 928, p. 167154.

J.Q. Li, J. Liu, and Z.S. Cui: Mater. Sci. Eng. A, 2015, vol. 643, pp. 32–36.

M.G. Jiang, H. Yan, and R.S. Chen: Mater. Des., 2015, vol. 87, pp. 891–900.

M. Avvari and S. Narendranath: J. Magnes. Alloys, 2014, vol. 2, pp. 159–64.

X.H. Huang, M.Z. Bian, and Y. Chino: Scr. Mater., 2022, vol. 215, p. 114709.

S. Kleiner and P.J. Uggowitzer: Mater. Sci. Eng. A, 2004, vol. 379, pp. 258–63.

S. Huang, M. Subramani, K. Borodianskiy, P.N. Immanuel, and C. Chiang: Mater. Today Commun., 2023, vol. 34, p. 104974.

Z.J. Zhang, L. Yuan, D.B. Shan, and B. Guo: Mater. Sci. Eng. A, 2021, vol. 827, p. 142036.

H.J. Kim, Y.J. Kim, and S.H. Park: J. Magnes. Alloys, 2023, vol. 11, pp. 671–83.

X.S. Huang, K. Suzuki, and N. Saito: Mater. Sci. Eng. A., 2009, vol. 508, pp. 226–33.

L.L. Tang, Y.H. Zhao, R.K. Islamgaliev, C.Y.A. Tsao, R.Z. Valiev, E.J. Lavernia, and Y.T. Zhu: Mater. Sci. Eng. A, 2016, vol. 670, pp. 280–91.

Y. Cubides, A.I. Karayan, M.W. Vaughan, I. Karaman, and H. Castaneda: Materialia, 2020, vol. 13, p. 100840.

G. Faraji, P. Yavari, S. Aghdamifar, and M.M. Mashhadi: J. Mater. Sci. Technol., 2014, vol. 30, pp. 134–38.

L. Chen, W. Li, Y. Sun, and M. Luo: J. Alloys Compd., 2022, vol. 923, p. 166495.

L. Zheng, X. Zhang, H. Wang, L. Wang, H. Hou, H. Li, and S.S. Kwang: J. Mater. Res. Technol., 2021, vol. 15, pp. 2459–70.

X. Xia, Q. Chen, Z. Zhao, M. Ma, X. Li, and K. Zhang: J. Alloys Compd., 2015, vol. 623, pp. 62–68.

B. Li, B. Teng, and G. Chen: Mater. Sci. Eng. A, 2019, vol. 744, pp. 396–405.

Acknowledgments

The authors gratefully acknowledge the financial supports received from the National Natural Science Foundation of China (Grant No. 51974376), the Natural Science Foundation of Hunan Province, China (Grant No. 2021JJ20063), and the Natural Science Foundation of Shanxi Province, China (Grant No. 20210302123163).

Conflict of interest

The authors declare that they have no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, T., Hu, S., Li, S. et al. Improving the Mechanical Properties of an Age-Hardenable Magnesium Alloy via Regulating Precipitate Scale and Building Dislocation Configuration. Metall Mater Trans A 54, 4770–4778 (2023). https://doi.org/10.1007/s11661-023-07198-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07198-3