Abstract

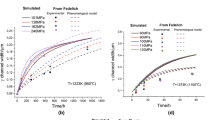

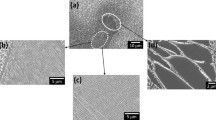

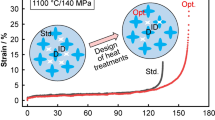

CMSX-4 is a technically important Ni-based superalloy which is used for various niche applications in the aerospace industries, owing to its excellent strength, fatigue, and creep resistances. However, the as-cast single-crystal alloy suffers from elemental segregation and micro-scale inhomogeneities, i.e., dendritic structure along with nano-scale γ/γʹ precipitates. A 16-fold enhancement in the withdrawal rate with respect to the commonly used one shows prominent microstructural refinement. The specialized heat treatment schedule along with higher withdrawal rate leads to the successful removal of micro- and nano-scale non-uniformities and elemental partitioning. Systematic nanoindentation-based investigation indicates higher hardness for faster withdrawal rate. Furthermore, localized nanoindentation reveals distinctly higher hardness for the dendrite as compared to inter-dendritic region in the as-cast condition. Most importantly, uniformity in localized hardness as well as least effect of size dependency is achieved upon optimally heat treating the superalloy. The gradual transition from elastic to plastic deformation behavior is noted for the as-cast alloy. Aged alloys, however, show excellent resistance to plastic deformation. Overall, a detailed insight is developed on the processing-structure-property correlation for CMSX-4 superalloy. Certainly, the newly designed faster withdrawal rate with homogenized microstructure can provide a reliable approach for manufacturing of single-crystal components.

Graphical Abstract

Similar content being viewed by others

References

T. Wang, H. Zhang, C. Liu, X. Gong, Y. Pei, Y. Zou, Y. Liu, and Q. Wang: J. Alloys Compd., 2022, vol. 912, 165175.

J. Yang, F. Jing, Z. Yang, K. Jiang, D. Hu, and B. Zhang: J. Alloys Compd., 2021, vol. 872, 159578.

X. Li, Y. Zhang, W. Li, S. Zhou, and P. Wang: Fatigue Fract. Eng. Mater. Struct., 2021, vol. 44, pp. 3431–47.

C. Zhang, P. Wang, Z. Wen, Z. Xu, P. He, and Z. Yue: J. Alloys Compd., 2022, vol. 890, 161710.

W. Xia, X. Zhao, L. Yue, and Z. Zhang: J. Alloys Compd., 2020, vol. 819, 152954.

E.A. Estrada Rodas, S. Gorgannejad, and R.W. Neu: Fatigue Fract. Eng. Mater. Struct., 2019, vol. 42, pp. 2155–71.

R.C. Reed: The Superalloys: Fundamentals and Applications, Cambridge University Press, Cambridge, 2008.

T.M. Pollock and S. Tin: J. C. power, 2006, vol. 22, pp. 361–74.

D. Szeliga, K. Kubiak, A. Burbelko, and M. Motyka: J. Sieniawski, 2014, vol. 23, pp. 1088–95.

H. Long, S. Mao, Y. Liu, Z. Zhang, and X. Han: J. Alloys Compd., 2018, vol. 743, pp. 203–20.

W. Xia, X. Zhao, L. Yue, and Z. Zhang: J. Mater. Sci. Technol., 2020, vol. 44, pp. 76–95.

M.S.A. Karunaratne, D.C. Cox, P. Carter, and R.C. Reed: Superalloys, 2000, vol. 2000, pp. 263–72.

K.Y. Cheng, C.Y. Jo, D.H. Kim, T. Jin, and Z.Q. Hu: Mater. Charact., 2008, vol. 60, pp. 210–18.

H. Yu, W. Xu, and S. Van Der Zwaag: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 406–16.

G.L. Erickson: JOM, 1995, vol. 47, pp. 36–39.

K. Harris and J.B. Wahl: Proc. Int. Symp. Superalloys, 2004, pp. 45–52.

B. Wahlmann, F. Galgon, A. Stark, S. Gayer, N. Schell, P. Staron, and C. Koerner: Acta Mater., 2019, vol. 180, pp. 84–96.

A. Ma, D. Dye, and R.C. Reed: Acta Mater., 2008, vol. 56, pp. 1657–70.

H. Zhang, Q. Wang, X. Gong, T. Wang, W. Zhang, K. Chen, C. Wang, Y. Liu, and Q. Wang: J. Alloys Compd., 2021, vol. 866, 158878.

Q. Li, J. Shen, L. Qin, and Y. Xiong: J. Mater. Process. Technol., 2019, vol. 274, 116308.

C. Körner, M. Ramsperger, C. Meid, D. Bürger, P. Wollgramm, M. Bartsch, and G. Eggeler: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 3781–92.

T. Isensee and D. Tourret: Acta Mater., 2022, p. 118035.

G. Matache, D.M. Stefanescu, C. Puscasu, and E. Alexandrescu: Int. J. Cast Met. Res., 2016, vol. 29, pp. 303–16.

R.C. Reed, T. Tao, and N. Warnken: Acta Mater., 2009, vol. 57, pp. 5898–5913.

A. Szczotok and B. Chmiela: J. Mater. Eng. Perform., 2014, vol. 23, pp. 2739–47.

Y. Zhao, M. Zhang, L. Yang, Y. Guo, J. Zhang, H. Lu, Y. Chen, and D. Tang: Prog. Nat. Sci. Mater. Int., 2021, vol. 31, pp. 493–500.

G. Liu, L. Liu, C. Ai, B. Ge, J. Zhang, and H. Fu: J. Alloys Compd., 2011, vol. 509, pp. 5866–72.

M. Lamm and R.F. Singer: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1177–83.

C. Ai, J. Zhou, S. Li, H. Zhang, Y. Pei, and S. Gong: J. Alloys Compd., 2016, vol. 660, pp. 159–65.

N. Ren, J. Li, B. Wang, L. Zeng, M. Xia, and J. Li: Mater. Des., 2021, vol. 198, 109347.

K. Gancarczyk, M. Zubko, A. Hanc-kuczkowska, B. Ko, R. Albrecht, D. Szeliga, M. Motyka, W. Ziaja, and J. Sieniawski: Materials, 2019, vol. 12, pp. 1–14.

A. Mirak and M. Fathi: Mater. Charact., 2022, vol. 194, 112449.

B.C. Wilson, E.R. Cutler, and G.E. Fuchs: Mater. Sci. Eng. A, 2008, vol. 479, pp. 356–64.

P. Hallensleben, H. Schaar, P. Thome, N. Jöns, A. Jafarizadeh, I. Steinbach, G. Eggeler, and J. Frenzel: Mater. Des., 2017, vol. 128, pp. 98–111.

P. Hallensleben, F. Scholz, P. Thome, H. Schaar, I. Steinbach, G. Eggeler, and J. Frenzel: Crystals, 2019, vol. 9, p. 149.

A.B. Parsa, P. Wollgramm, H. Buck, C. Somsen, A. Kostka, I. Povstugar, P.P. Choi, D. Raabe, A. Dlouhy, J. Müller, E. Spiecker, K. Demtroder, J. Schreuer, K. Neuking, and G. Eggeler: Adv. Eng. Mater., 2015, vol. 17, pp. 216–30.

F. Scholz, M. Cevik, P. Hallensleben, P. Thome, G. Eggeler, and J. Frenzel: Materials, 2021, vol. 14, p. 4904.

O.M. Horst, D. Adler, P. Git, H. Wang, J. Streitberger, M. Holtkamp, N. Jöns, R.F. Singer, C. Körner, and G. Eggeler: Mater. Des., 2020, vol. 195, 108976.

I. Lopez-Galilea, J. Koßmann, A. Kostka, R. Drautz, L. Mujica Roncery, T. Hammerschmidt, S. Huth, and W. Theisen: J. Mater. Sci., 2016, vol. 51, pp. 2653–64.

R. Rettig, K. Matuszewski, A. Müller, H.E. Helmer, N.C. Ritter, and R.F. Singer: Studies, 2016, vol. 21, p. 23.

J. Rame, S. Utada, L.M. Bortoluci Ormastroni, L. Mataveli-Suave, E. Menou, L. Després, P. Kontis, and J. Cormier: in Superalloys 2020: Proceedings of the 14th International Symposium on Superalloys, Springer, 2020, pp. 71–81.

ASTM E3-95: ASTM Int., 2016, vol. 82, pp. 1–15.

G.M. Pharr and W.C. Oliver: J. Mater. Res., 1992, vol. 7, pp. 613–17.

C.L. Brundidge, D. Van Drasek, B. Wang, and T.M. Pollock: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 965–76.

F. Wang, D. Ma, J. Zhang, S. Bogner, and A. Bührig-polaczek: Mater. Charact., 2015, vol. 101, pp. 20–25.

F. Wang, D. Ma, J. Zhang, L. Liu, J. Hong, S. Bogner, and A. Bührig-Polaczek: J. Cryst. Growth, 2014, vol. 389, pp. 47–54.

B.C. Wilson, J.A. Hickman, and G.E. Fuchs: JOM, 2003, vol. 55, pp. 35–40.

M.L. Clemens, A.R. Price, and R.S. Bellows: Adv. Mater. Process. Gas Turbines, 2002, pp. 111–18.

M. Krčmar, C.L. Fu, A. Janotti, and R.C. Reed: Acta Mater., 2005, vol. 53, pp. 2369–76.

Y. Li, Z. Jia, W. Tang, X. Liang, W. Xu, and Y. Zhao: Adv. Eng. Mater., 2020, vol. 22, p. 1901151.

G.E. Fuchs: Mater. Sci. Eng. A, 2001, vol. 300, pp. 52–60.

S.R. Hegde, R.M. Kearsey, and J. Beddoes: TMS, Superalloys.

M. Ramsperger, R.F. Singer, and C. Körner: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 1469–80.

A. Szczotok and R. Przeliorz: IOP Conf. Ser. Mater. Sci. Eng., https://doi.org/10.1088/1757-899X/35/1/012005.

H.T. Pang, N. D’souza, H. Dong, H.J. Stone, and C.M.F. Rae: Metall. Mater. Trans. A, 2016, vol. 47A, pp. 889–906.

S. Steuer, P. Villechaise, T.M. Pollock, and J. Cormier: Mater. Sci. Eng. A, 2015, vol. 645, pp. 109–115.

M. Shahwaz, P. Nath, and I. Sen: J. Alloys Compd., 2022, p. 164530.

M.D. Uchic, D.M. Dimiduk, J.N. Florando, and W.D. Nix: Science, 2004, vol. 305, pp. 986–89.

G.M. Pharr, E.G. Herbert, and Y. Gao: Annu. Rev. Mater. Res., 2010, vol. 40, pp. 271–92.

W.D. Nix and H. Gao: J. Mech. Phys. Solids.

M.A. Mattucci, I. Cherubin, P. Changizian, T. Skippon, and M.R. Daymond: Acta Mater., 2021, vol. 207, 116702.

X. Qiu, Y. Huang, W.D. Nix, K.C. Hwang, and H. Gao: Acta Mater., 2001, vol. 49, pp. 3949–58.

P. Changizian, A. Brooks, Z. Yao, and M.R. Daymond: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 498–514.

S. Kumar, I.A. Kumar, L. Marandi, and I. Sen: Acta Mater., 2020, vol. 201, pp. 303–15.

F. Pöhl: Sci. Rep., 2019, vol. 9, pp. 1–12.

X. Lu, Y. Ma, D. Peng, R. Johnsen, and D. Wang: J. Mater. Sci. Technol., 2023, vol. 135, pp. 156–69.

S. Jiapeng, L. Cheng, J. Han, A. Ma, and L. Fang: Sci. Rep., 2017, vol. 7, pp. 1–12.

J. Ruzic, K. Goto, I. Watanabe, T. Osada, L. Wu, and T. Ohmura: Mater. Sci. Eng. A, 2021, vol. 818, 141439.

D.J. Crudden, A. Mottura, N. Warnken, B. Raeisinia, and R.C. Reed: Acta Mater., 2014, vol. 75, pp. 356–70.

S. Tian, J. Wu, D. Shu, Y. Su, H. Yu, and B. Qian: Mater. Sci. Eng. A, 2014, vol. 616, pp. 260–67.

T. Ichitsubo, D. Koumoto, M. Hirao, K. Tanaka, M. Osawa, T. Yokokawa, and H. Harada: Acta Mater., 2003, vol. 51, pp. 4033–44.

P. Zhang, Y. Yuan, B. Li, S.W. Guo, G.X. Yang, and X.L. Song: Mater. Sci. Eng. A, 2016, vol. 655, pp. 152–59.

Z.W. Lian, J.J. Yu, X.F. Sun, H.R. Guan, and Z.Q. Hu: Mater. Sci. Eng. A, 2008, vol. 489, pp. 227–33.

T. Ning, T. Sugui, Y. Huajin, S. Delong, Z. Shunke, and Z. Guoqi: Mater. Sci. Eng. A, 2019, vol. 744, pp. 154–62.

J. Zhang, T. Huang, K. Cao, J. Chen, H. Zong, D. Wang, J. Zhang, J. Zhang, and L. Liu: J. Mater. Sci. Technol., 2021, vol. 75, pp. 68–77.

J.S. Van Sluytman and T.M. Pollock: Acta Mater., 2012, vol. 60, pp. 1771–83.

Acknowledgments

PN, SR, and IS acknowledge the Central Research Facility of IIT Kharagpur for required research facilities. IS acknowledges the support by Alexander von Humboldt Foundation through renewed research stay, for the collaboration with Ruhr University, Bochum, Germany. FS acknowledges funding from the Alexander von Humboldt Foundation through a Feodor Lynen Research Fellowship. FS, JP, JF, and GE acknowledges the German Research Foundation (Deutsche Forschungsgemeinschaft, DFG) for funding through the collaborative research center SFB TR 103, projects B5 and B7 (see: www.sfb-transregio103.de).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nath, P., Scholz, F., Pfetzing, J. et al. Influence of Microstructural Homogenization on the Localized Deformation Behavior of Single-Crystal Ni-Based Superalloy, CMSX-4. Metall Mater Trans A 54, 4498–4514 (2023). https://doi.org/10.1007/s11661-023-07183-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07183-w