Abstract

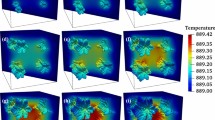

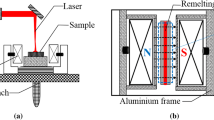

Suppressing the melt convection in the solidifying ingot is still considered to be a challenging task. By applying a high-magnetic field (HMF), we achieved a diffusive condition for the crystal growth. The atomic interdiffusion coefficient in the Al–Cu melt was measured in the HMF to define the critical magnetic flux density (MFD) for the diffusive crystal growth in the melt. A diffusive growth state was achieved in the melt when the MFD was greater than a critical 2.9 T. The influence of HMF on crystal growth was investigated by X-ray computed tomography. The HMF increased the size of crystal, but it decreased the crystal number and the curvature of dendrite tips as well as the specific surface area of dendrite. A transition of dendritic arms from seaweed to dendrite was observed after applying an HMF. Interface shape distribution maps showed that the HMF increased the proportion of ellipsoid shapes and decreased the proportion of hyperbolic shapes of solid–liquid interface. These were attributed to the decrease of constitutional supercooling caused by the magnetohydrodynamic effect. This work provides a new path to obtain a diffusive condition for crystal growth.

Similar content being viewed by others

References

A. Bogno, H. Nguyen-Thi, A. Buffet, G. Reinhart, B. Billia, N. Mangelinck-Noël, N. Bergeon, J. Baruchel, and T. Schenk: Acta Mater., 2011, vol. 59, pp. 4356–65.

T. Nelson, B. Cai, N. Warnken, P.D. Lee, E. Boller, O.V. Magdysyuk, and N.R. Green: Scripta Mater., 2020, vol. 180, pp. 29–33.

H. Nguyen-Thi, Y. Dabo, B. Drevet, M.D. Dupouy, D. Camel, B. Billia, J.D. Hunt, and A. Chilton: J. Cryst. Growth, 2005, vol. 281, pp. 654–68.

N. Bergeon, G. Reinhart, F.L. Mota, N. Mangelinck-Noël, and H. Nguyen-Thi: Eur. Phys. J. E, 2021, vol. 44, p. 98.

S. Akamatsu and H. Nguyen-Thi: Acta Mater., 2016, vol. 108, pp. 325–46.

F. Ngomesse, G. Reinhart, H. Soltani, G. Zimmermann, D.J. Browne, W. Sillekens, and H. Nguyen-Thi: Acta Mater., 2021, vol. 221, p. 117401.

A.G. Murphy, R.H. Mathiesen, Y. Houltz, J. Li, C. Lockowandt, K. Henriksson, N. Melville, and D.J. Browne: J. Cryst. Growth, 2016, vol. 454, pp. 96–104.

D.R. Liu, N. Mangelinck-Noël, C.A. Gandin, G. Zimmermann, L. Sturz, H. Nguyen-Thi, and B. Billia: Acta Mater., 2014, vol. 64, pp. 253–65.

R. Jansen and P.R. Sahm: Mater. Sci. Eng., 1984, vol. 65, pp. 199–212.

Y.Z. Li, N. Mangelinck-Noel, G. Zimmermann, L. Sturz, and H. Nguyen-Thin: J. Cryst. Growth, 2019, vol. 513, pp. 20–29.

H. Nguyen-Thi, G. Reinhart, and B. Billia: CR Mec., 2017, vol. 345, pp. 66–77.

H.P. Utech and M.C. Flemings: J. Appl. Phys., 1966, vol. 37, pp. 2021–24.

D.T.J. Hurle, E. Jakeman, and C.P. Johnson: J. Fluid Mech., 1974, vol. 64, pp. 565–76.

B. Zhou, W. Lin, Z. Shen, T. Zheng, Y. Zhong, E. Beaugnon, F. Debray, L. Zhang, H. Wang, and Q. Wang: J. Alloys Compd., 2021, vol. 879, p. 160410.

T. Zheng, Y. Zhong, Z. Lei, W. Ren, Z. Ren, D. Francois, B. Eric, and F. Yves: J. Alloys Compd., 2015, vol. 623, pp. 36–41.

Y. Zhong, T. Zheng, L. Dong, B. Zhou, W. Ren, J. Wang, Z. Ren, F. Debray, B. Eric, H. Wang, Q. Wang, Y. Dai, and X. Wei: Mater. Des., 2016, vol. 100, pp. 168–74.

G. Mathiak and G. Frohberg: Cryst. Res. Technol., 1999, vol. 34, pp. 181–88.

F. Onishi, T. Miyake, Y. Inatomi, and K. Kuribayashi: Microgravity Sci. Technol., 2006, vol. 18, pp. 86–90.

T. Miyake, Y. Inatomi, and K. Kuribayashi: Jpn. J. Appl. Phys., 2002, vol. 41, pp. L811-13.

Y. Liu, W. Lin, B. Zhou, T. Zheng, Y. Zhong, and L. Zhang: Rev. Sci. Instrum., 2021, vol. 92, p. 094903.

J. Wang, Y. Fautrelle, Z.M. Ren, H. Nguyen-Thi, G. Salloum Abou Jaoude, G. Reinhart, N. Mangelinck-Noël, X. Li, and I. Kaldre: Appl. Phys. Lett., 2014, vol. 104, p. 121916.

R. Moreau, O. Laskar, and M. Tanaka: Mater. Sci. Eng. A, 1993, vol. 173, pp. 93–100.

X. Li, Y. Fautrelle, Z. Ren, A. Gagnoud, R. Moreau, Y. Zhang, and C. Esling: Acta Mater., 2009, vol. 57, pp. 1689–1701.

X. Li, Y. Fautrelle, and Z. Ren: Acta Mater., 2007, vol. 55, pp. 3803–13.

X. Li, Y. Fautrelle, and Z. Ren: Acta Mater., 2008, vol. 56, pp. 3146–61.

X. Li, A. Gagnoud, Z. Ren, Y. Fautrelle, and R. Moreau: Acta Mater., 2009, vol. 57, pp. 2180–97.

Z. Shen, M. Peng, D. Zhu, T. Zheng, Y. Zhong, W. Ren, C. Li, W. Xuan, and Z. Ren: J. Mater. Sci. Technol., 2019, vol. 35, pp. 568–77.

J. Wang, S. Yue, Y. Fautrelle, P.D. Lee, X. Li, Y. Zhong, and Z. Ren: Sci. Rep., 2016, vol. 6, p. 24585.

W. Lin, B. Zhou, Y. Liu, X. Guo, T. Zheng, Y. Zhong, L. Zhang, Q. Zhang, and Q. Wang: J. Alloys Compd., 2022, vol. 918, p. 165679.

B. Zhang, A. Griesche, and A. Meyer: Phys. Rev. Lett., 2010, vol. 104, p. 035902.

E. Sondermann, N. Jakse, K. Binder, A. Mielke, D. Heuskin, F. Kargl, and A. Meyer: Phys. Rev. B, 2019, vol. 99, p. 024204.

H. Yasuda, I. Ohnaka, R. Ishit, S. Fujita, and Y. Tamura: ISIJ Int., 2005, vol. 45, pp. 991–96.

L. Li, R. Zhang, C. Ban, H. Zhang, T. Liu, H. Zhang, X. Wang, C. Esling, and J. Cui: Mater. Charact., 2019, vol. 151, pp. 191–202.

S.Y. He, T.J. Zhan, C.J. Li, W.D. Xuan, J. Wang, and Z.M. Ren: Mater. Trans., 2019, vol. 60, pp. 1921–27.

J. Alkemper and P.W. Voorhees: Acta Mater., 2001, vol. 49, pp. 897–902.

D. Kammer and P. Voorhees: Acta Mater., 2006, vol. 54, pp. 1549–58.

H. Henein, A.A. Bogno, W. Hearn, and J. Valloton: J. Phase Equilib. Diffus., 2020, vol. 41, pp. 784–92.

J.A. Dantzig, P.D. Napoli, J. Friedli, and M. Rappaz: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 5532–43.

M. Amoorezaei, S. Gurevich, and N. Provatas: Acta Mater., 2010, vol. 58, pp. 6115–24.

H. Xing, M.Y. Ji, X.L. Dong, Y.M. Wang, L.M. Zhang, and S.M. Li: Mater. Des., 2020, vol. 185, p. 108250.

G. Azizi, S. Kavousi, and M.A. Zaeem: Acta Mater., 2022, vol. 231, p. 117859.

Y. Chen, B. Billia, D.Z. Li, H. Nguyen-Thi, N.M. Xiao, and A.-A. Bogno: Acta Mater., 2014, vol. 66, pp. 219–31.

H. Xing, X. Dong, H. Wu, G. Hao, J. Wang, C. Chen, and K. Jin: Sci. Rep., 2016, vol. 6, p. 26625.

V.T. Witusiewicz, L. Sturz, A. Viardin, C. Pickmann, and G. Zimmermann: Acta Mater., 2021, vol. 216, p. 117086.

J.L. Fife and P.W. Voorhees: Acta Mater., 2009, vol. 57, pp. 2418–28.

H. Yu, K.N. Tandon, and J.R. Cahoon: Metal. Mater. Trans. A, 1997, vol. 28A, pp. 1245–50.

P. Lehmann, R. Moreau, D. Camel, and R. Bolcato: Acta Mater., 1988, vol. 46, pp. 4067–79.

X. Li, Y. Fautrelle, Z.M. Ren, Y.D. Zhang, and C. Esling: Acta Mater., 2010, vol. 58, pp. 2430–41.

W. Kurz, and D. J. Fisher: Fundamentals of Solidification, 3rd ed., Trans Tech Publications, Bach, 1992.

Acknowledgments

The authors gratefully acknowledge the Natural Science Foundation of Shanghai (21ZR1424400), the financial support of the National Natural Science Foundation of China (U1732276, U21A20114), and the Changjiang Scholars Program of China, China Association for Science and Technology Young Talent Support Project. We also acknowledge Y. L. Li for assistance with the X-ray scanning.

Data Availability

Data will be made available on request.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lin, W., Zhou, B., Zheng, T. et al. X-Ray Tomographic Quantification of Diffusive Growth of Metallic Dendrite in High Magnetic Field. Metall Mater Trans A 54, 4295–4305 (2023). https://doi.org/10.1007/s11661-023-07164-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07164-z