Abstract

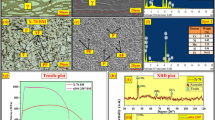

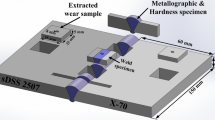

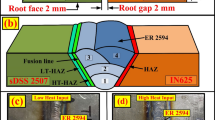

Gas tungsten arc welding (GTAW) is a widely used process in marine and offshore applications to produce high-quality dissimilar welded joints (DWJs). However, the structural integrity of the welded joint depends on the heat input and filler metal application. This study investigated the microstructure–mechanical integrity and residual stresses of a multipass GTAW joint between super duplex stainless steel (sDSS 2507) and Inconel 625 (IN-625) utilizing ERNiCrMo-3 filler and two heat inputs (0.73 and 1.4 kJ/mm). This is a typical dissimilar joint found in oil and gas pipelines, and risers used to extract hydrocarbons. To understand the effect of the microstructure evolution on the mechanical behavior, the microstructure of the lower heat input (LHI) and higher heat input (HHI) weldments was compared. The optical image and secondary electron spectroscopy revealed an austenitic microstructure with an equiaxed, columnar, and cellular morphology in the LHI and HHI weld zones, with a Ni weight percentage of 52.40 pct. An unmixed zone (UZ) was found at the LHI and HHI weld zones and sDSS 2507 base metal interface but not at the IN-625 interface. NbC and Laves phases were found in the interdendritic region by energy-dispersive X-ray spectroscopy. Mechanical testing, including microhardness behavior, tensile properties, and impact toughness, was conducted in various weld regions following standard procedures at room temperature. The study also used deep hole drilling (DHD) methods to assess residual stresses of both LHI and HHI weld zone and determine whether heat input influenced these stresses. The LHI and HHI specimens’ average ultimate tensile strength and percent elongation values were determined to be 800 ± 7 MPa and 27 ± 2 pct and 857 ± 5 MPa and 29 ± 3 pct, respectively. The microhardness maps demonstrated variations in the weld zones for both heat input weldments. The weld zone’s hardness varied from 260 to 360 Hv0.5, with an average of 280 ± 6 Hv0.5 for LHI and 300 ± 4 Hv0.5 for HHI weldment. Impact toughness for the LHI weldment was 155 ± 3 and 160 ± 2 J for the cap and root regions, respectively, while it was 185 ± 7 and 195 ± 3 J for the HHI weldment. The DHD approach was utilized to analyze the distribution of residual stresses in the weld zone of both heat input weldments. Both the LHI and HHI joints showed a significant variation in residual stresses, with the HHI weldment exhibiting higher residual stress magnitudes for both tangential (21 pct) and longitudinal (23 pct) directions. The sDSS 2507/IN-625 DWJ was optimally fabricated without significant defects and with adequate mechanical performance to be considered for use in oil and gas pipelines and risers used in hydrocarbon extraction in accordance with ASTM specifications.

Similar content being viewed by others

References

R. Chhibber, N. Arora, S.R. Gupta, and B.K. Dutta: Proc. Inst. Mech. Eng. C, 2006, vol. 220, pp. 1121–133.

J.C. Lippold and D.J. Kotecki: Welding Metallurgy and Weldability of Stainless Steels, Wiley, Hoboken, NJ, 2005, p. 376.

G. Dak and C. Pandey: J. Manuf. Process., 2022, vol. 80, pp. 829–51.

J.C. Lippold: Welding Metallurgy and Weldability, vol. 9781118230, Wiley, Hoboken, NJ, 2014.

A. Pramanik, G. Littlefair, and A.K. Basak: Mater. Manuf. Process., 2015, vol. 30, pp. 1053–068.

J.N. Dupont, J.C. Lippold, and S.D. Kiser: Welding Metallurgy and Weldability of Nickel-Base Alloys, Wiley, Hoboken, 2011.

A. Chabbi, M. Bouabdallah, S. Sao-Joao, A. Boudiaf, and G. Kermouche: Metall. Res. Technol., 2020, vol. 117, p. 407.

R. Sridhar, K.D. Ramkumar, and N. Arivazhagan: Acta Metall. Sin. (Engl. Lett.), 2014, vol. 27, pp. 1018–030.

K. Devendranath Ramkumar, P.S.G. Kumar, V. Sai Radhakrishna, K. Kothari, R. Sridhar, N. Arivazhagan, and P. Kuppan: J. Mater. Res., 2015, vol. 30, pp. 3288–98.

V. Shankar, K. Bhanu Sankara Rao, and S.L. Mannan: J. Nucl. Mater., 2001, vol. 288, pp. 222–32.

H. Boehm, K. Ehrlich, and K.H. Kramer: Metall, 1970, vol. 24, pp. 139–44.

A. Gunen and E. Kanca: Revista Materia, 2017, https://doi.org/10.1590/S1517-707620170002.0161.

P.K. Korrapati, V.K. Avasarala, M. Bhushan, K. Devendranath Ramkumar, N.N. Arivazhagan, and S. Narayanan: Procedia Engineering, vol. 75, Elsevier Ltd, Amsterdam, 2014, pp. 9–13.

R. Bews: Weld. J., 2002, vol. 81, pp. 36–9.

A.K. Maurya, C. Pandey, and R. Chhibber: Mater. Manuf. Process., 2023, vol. 38, pp. 379–400.

A.K. Maurya, R. Chhibber, and C. Pandey: J. Mater. Eng. Perform., 2022, vol. 31, pp. 1–34.

A. Kumar and C. Pandey: Metall. Mater. Trans. A., 2022, vol. 53A, pp. 3245–273.

K.D. Ramkumar, S. Oza, S. Periwal, N. Arivazhagan, R. Sridhar, and S. Narayanan: Ciência & Tecnologia dos Materiais, 2015, vol. 27, pp. 41–52.

V. Bhanu, C. Pandey, and A. Gupta: CIRP J. Manuf. Sci. Technol., 2022, vol. 38, pp. 560–80.

G. Dak and C. Pandey: Int. J. Press. Vessels Pip., 2021, vol. 194, p. 104536.

Z. Zhou and J. Löthman: Weld. World, 2017, vol. 61, pp. 21–33.

A. Eghlimi, M. Shamanian, M. Eskandarian, A. Zabolian, and J.A. Szpunar: Mater. Charact., 2015, vol. 106, pp. 27–35.

W.N. Khan and R. Chhibber: Proc. Inst. Mech. Eng. L, 2021, vol. 235, pp. 1827–840.

N. Nissley, T.D. Anderson, F.F. Noecker, C. Roepke, M. Gallagher, and M. Hukle: Proc. Int. Conf. Offshore Mech. Arct. Eng. - OMAE, American Society of Mechanical Engineers (ASME), New York, 2014, vol. 5.

J. Kangazian and M. Shamanian: J. Manuf. Process., 2017, vol. 26, pp. 407–18.

B. Varbai, P. Bolyhos, D.M. Kemény, and K. Májlinger: Period. Polytech. Mech. Eng., 2022, vol. 66, pp. 344–49.

C. Payares-Asprino: Adv. Mater. Sci., 2021, vol. 21, pp. 75–90.

A.K. Maurya, C. Pandey, and R. Chhibber: Arch. Civ. Mech. Eng., 2022, vol. 22, p. 90.

E.A. Zadeh, M. Masaeli, and R. Dehmolaye: J. Basic Appl. Adv. Sci., 2016, vol. 4, pp. 1–7.

A.K. Maurya, R. Chhibber, and C. Pandey: J. Mater. Sci., 2016, vol. 58, pp. 1–38. https://doi.org/10.1007/s10853-023-08562-9.

H. Vemanaboina, B. Sridhar Babu, E. Gundabattini, P. Ferro, and K. Kumar: Adv. Mater. Sci. Eng., 2021, vol. 2021, pp. 1–9.

A.Z. Ramay, T. Shehbaz, F.N. Khan, M. Junaid, and A. Iltaf: Proc. Inst. Mech. Eng. C, 2022, vol. 236, pp. 6077–94.

M. Sadeghian, M. Shamanian, and A. Shafyei: Mater. Des., 2014, vol. 60, pp. 678–84.

H. Tasalloti, P. Kah, and J. Martikainen: Mater. Charact., 2017, vol. 123, pp. 29–41.

M. Vahman, M. Shamanian, M.A. Golozar, A. Jalali, M.A. Sarmadi, and J. Kangazian: Steel Res. Int., 2019, https://doi.org/10.1002/SRIN.201900347.

V.A. Hosseini, K. Hurtig, and L. Karlsson: Mater. Corros., 2017, vol. 68, pp. 405–15.

N. Ouali, K. Khenfer, B. Belkessa, J. Fajoui, B. Cheniti, B. Idir, and S. Branchu: J. Mater. Eng. Perform., 2019, vol. 28, pp. 4252–264.

E. Ranjbarnodeh, S. Serajzadeh, A. Hosein Kokabi, S. Hanke, and A. Fischer: Int. J. Adv. Manuf. Technol., 2011, vol. 55, pp. 649–56.

R. Unnikrishnan, K.S.N.S. Idury, T.P. Ismail, A. Bhadauria, S.K. Shekhawat, R.K. Khatirkar, and S.G. Sapate: Mater. Charact., 2014, vol. 93, pp. 10–23.

H. Vemanaboina, G. Edison, and S. Akella: Mater. Res. Express, 2019, vol. 6, p. 096519.

M. Vahman, M. Shamanian, M.A. Golozar, A. Jalali, M.A. Sarmadi, and J. Kangazian: Steel Res. Int., 2020, vol. 91, p. 1900347.

C. Köse and C. Topal: J. Manuf. Process., 2022, vol. 73, pp. 861–94.

W.N. Khan and R. Chhibber: Mater. Sci. Eng. A, 2021, vol. 803, p. 140476.

American Welding Society (AWS): Code-Steel and Structural Welding: “AWS D1. 1/D1. 1M”, American Welding Society, Miami, Florida, 2010.

J.N. DuPont and A.R. Marder: Weld. J.-Incl. Weld. Res. Suppl., 1995, vol. 74, p. 406s.

F.A. Cotrim-Ferreira, C.L. Quaglio, R.P.V. Peralta, P.E.G. Carvalho, and D.F. Siqueira: Braz. Oral Res., 2010, vol. 24, pp. 438–2.

ASTM E 407-93: Standard Practice for Microetching Metals and Alloys, ASTM International, USA, 1997.

ASTM E92–16: Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials, ASTM International, West Conshohocken, 2016.

ASTM E8: Annual Book of ASTM Standards 4, ASTM International, West Conshohocken, 2010, pp. 1–27.

ASTM American Society for Testing and Materials and ASTM E 23–12c: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials, ASTM International, West Conshohocken, 2013. https://www.astm.org/e0837-20.html

E. 837-01 ASTM: Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method, 1986. https://www.sciencedirect.com/book/9780080570693/theory-of-elasticity

S.P. Timoshenko and J.N. Goodier: Theory of Elasticity. Chameleon Press, Birmingham.

N.W. Bonner and D.J. Smith: Measurement of Residual Stresses in a Thick Section Steel Weld, 1994, pp. 259–74.

P.K. Taraphdar, R. Kumar, C. Pandey, and M.M. Mahapatra: Met. Mater. Int., 2021, vol. 27, pp. 3478–492.

P. Kumar Taraphdar, M.M. Mahapatra, A. Kumar Pradhan, P.K. Singh, K. Sharma, and S. Kumar: Met. Mater. Int., 2021, https://doi.org/10.1177/0954405421990124.

J.N. Dupont: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3612–620.

S. Kumar, V.K. Yadav, S.K. Sharma, C. Pandey, A. Goyal, and P. Kumar: Int. J. Press. Vessels Pip., 2021, vol. 193, p. 104443.

I. Bunaziv, V. Olden, and O.M. Akselsen: Appl. Sci., 2019, vol. 9, art. no. 3118.

S. Kou: Weld. Metall., 2003, vol. 2, pp. 199–202.

X. Li and W. Tan: Comput. Mater. Sci., 2018, vol. 153, pp. 159–69.

F. Liu, F. Lyu, F. Liu, X. Lin, and C. Huang: J. Market. Res., 2020, vol. 9, pp. 9753–765.

Y. Wang, H. Cui, M. Fan, Y. Chen, and F. Lu: Mater. Charact., 2019, vol. 151, pp. 227–36.

A.K. Maurya, C. Pandey, and R. Chhibber: Int. J. Press. Vessels Pip., 2021, vol. 192, 104439.

EN ISO15614-1: ISO Standards, 2017, vol. 2, International Organization for Standardization, London, pp. 1–38.

A. Skouras, A. Paradowska, M.J. Peel, P.E.J. Flewitt, and M.J. Pavier: Int. J. Press. Vessels Pip., 2013, vol. 101, pp. 143–53.

Funding

No funding is received for the work.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

Author(s) have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maurya, A.K., Chhibber, R. & Pandey, C. GTAW Dissimilar Weldment of sDSS 2507 and Nickel Alloy for Marine Applications: Microstructure–Mechanical Integrity. Metall Mater Trans A 54, 3311–3340 (2023). https://doi.org/10.1007/s11661-023-07101-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07101-0