Abstract

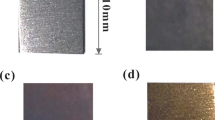

In this study, scanning electron microscopy, differential scanning calorimetry, X-ray photoelectron spectroscopy, and electrochemical workstation were used to study the effect of KCl–ZnCl2 ball-milling fluxing on the microstructure and corrosion of iron ingot hot-dip zinc coatings. The results show that compared with the solvent fluxing (S) NH4Cl–ZnCl2 and NH4Cl–ZnCl2–FeCl2, ball-milling fluxing (BM) KCl–ZnCl2 increases the thermal decomposition temperature of the ZnCl2·H2O salt and increases the thermostability of the fluxing salt film. KCl replaces NH4Cl, avoiding the white smoke particles produced by the condensation of NH3 and HCl. There are ζ and δ layers in the coating obtained by S-(NH4Cl–ZnCl2–FeCl2). The coatings obtained by S-(NH4Cl–ZnCl2) and BM-(KCl–ZnCl2) are the same, with η, ζ, and δ layers. In electrochemical corrosion, the η layer acts as the sacrificial anode, which delays the corrosion of the ζ layer and plays the sacrificial protection for the coating. Besides, in corrosion, the corrosion products generated by the η-layer are deposited on the coating surface. These corrosion products constitute the passivation film, which hinders the further development of corrosion and plays the barrier protection for the coating.

Graphical Abstract

Similar content being viewed by others

References

H. Kania, J. Mendala, J. Kozuba, and M. Saternus: Materials, 2020, vol. 13, pp. 1–24.

Z.W. Li, H.P. Peng, Y. Liu, J.H. Wang, and X.P. Su: Trans. Indian Inst. Met., 2022, vol. 75, pp. 397–406.

S. Peng, S.K. Xie, J.T. Lu, and L.C. Zhang: J. Alloys Compd., 2017, vol. 728, pp. 1002–008.

Z.W. Li, H.P. Peng, Y. Liu, S.P. Su, S. Kawi, and J.H. Wang: J. Mater. Res. Technol., 2022, vol. 16, pp. 1402–412.

T.A. Pozdniakova, L.P. Mazur, R.A.R. Boaventyra, and V.J.P. Vilar: J. Clean. Prod., 2016, vol. 119, pp. 38–49.

M. Manna, G. Naidu, N. Rani, and N. Bandyopadhyay: Surf. Coat. Technol., 2008, vol. 202, pp. 1510–516.

T. Bellezze, S. Saltykov, G. Roventi, M. Malavolta, and R. Fratesi: Surf. Coat. Technol., 2012, vol. 206, pp. 5023–027.

R. Friess: Z. Anorg. Chem., 1903, vol. 206, pp. 3083–087.

N. Pistofidis, G. Vourlias, S. Konidaris, E. Pavlidou, G. Stergioudis, and D. Tsipas: Cryst. Res. Technol., 2006, vol. 41, pp. 759–65.

S. Kahar, H. Panchal, and R. Patel: Int. J. Adv. Eng. Res. Dev., 2014, vol. 1, pp. 30–6.

W. Wołczynski, Z. Pogoda, G. Garzel, B. Kucharska, A. Sypien, and T. Okane: Arch. Metall. Mater., 2014, vol. 59, pp. 1393–404.

B.D. Deshmukh and A.P. Patil: Int. J. Emerg. Technol. Adv. Eng., 2012, vol. 2, pp. 71–5.

S. Roy, Y. Liu, M. Topsakal, E. Dias, R. Gakhar, W.C. Phillips, J.F. Wishart, and D. Leshchev: J. Am. Chem. Soc., 2021, vol. 143, pp. 15298–5308.

A.M.P. Simoes, R.O. Carbonari, A.R. Sarli, B.D. Amo, and R. Romagnoli: Corros. Sci., 2011, vol. 53, pp. 464–72.

J. Wang, Y.Y. Zhang, K.K. Cui, T. Fu, J.J. Gao, and S.H. Hussain: J. Clean. Prod., 2021, vol. 298, 126788.

Y. Boonyongmaneerate, K. Saenkiettiyut, P. Rattanawaleedirojn, C. Angkaprasert, J. Wanichsapan, and S. Saenapitak: J. Iron Steel Res. Int., 2010, vol. 17, pp. 74–8.

T. Liu, R. Ma, Y.Z. Fan, A. Du, X. Zhao, M. Wen, and X.M. Cao: Surf. Coat. Technol., 2018, vol. 337, pp. 270–78.

J.D. Hernández-Betancur, H.F. Hernandez, and L.M. Ocampo-Carmona: J. Clean. Prod., 2019, vol. 206, pp. 755–66.

R.E. Elewa, S.A. Afolalu, and O.S.I. Fayomi: International Conference on Engineering for Sustainable World, 2019, vol. 1378, pp. 022071.

G. Kong and R. White: J. Clean. Prod., 2010, vol. 18, pp. 1092–099.

B.B. Zhang, W.C. Xu, Q.J. Zhu, and B.R. Hou: J. Mater. Sci. Technol., 2021, vol. 66, pp. 74–81.

T.J. Pan, W.M. Lu, Y.J. Ren, and W.T. Wu: Oxid. Met., 2009, vol. 72, pp. 179–90.

A. Ul-Hamid: Cham, 2018. ISBN 978-3-319-98482-7.

G.W.H. Höhne, W.F. Hemminger, and H.J. Flammersheim: Applications of Differential Scanning Calorimetry, Springer, Berlin, 2003, pp. 147–244.

A.P. Yadav, H. Katayama, K. Noda, H. Masuda, A. Nishikata, and T. Tsuru: Corros. Sci., 2007, vol. 49, pp. 3716–731.

A.R. Marder: Prog. Mater. Sci., 2000, vol. 45, pp. 191–271.

C.J. Li, P.W. Li, K. Wang, and E.E. Molina: AIMS Energy, 2014, vol. 2, pp. 133–57.

S. Niazi, E. Olsen, and H.S. Nygard: J. Mol. Liq., 2020, vol. 317, 114069.

Z. Yu, J.M. Hu, and H.M. Meng: Front. Mater., 2020, vol. 7, pp. 1–7.

P.C.J. Graat and M.A.J. Somers: Appl. Surf. Sci., 1996, vol. 101, pp. 36–40.

X.L. Shang, B. Zhang, E.H. Han, and W. Ke: Electrochim. Acta, 2011, vol. 56, pp. 1417–425.

P. Kaspar, D. Sobola, R. Dallaev, S. Ramazanov, A. Nebojsa, S. Rezaee, and L. Grmela: Appl. Surf. Sci., 2019, vol. 493, pp. 673–78.

P. Ghods, O.B. Isgor, J.R. Brown, F. Bensebaa, and D. Kingston: Appl. Surf. Sci., 2011, vol. 257, pp. 4669–677.

E. Diler, B. Lescop, S. Rioual, G. Nguyen, D. Thierry, and B. Rouvelou: Corros. Sci., 2014, vol. 79, pp. 83–8.

X. Zhang, C. Leygraf, and L.O. Wallinder: Corros. Sci., 2013, vol. 73, pp. 62–71.

Z.H. Wang, C.T. Chen, J.C. Liu, G. Zhang, and K. Suganuma: Corros. Sci., 2018, vol. 140, pp. 40–50.

T.M.C. Nogueira, U.R. Seixas, and P.R. Rios: ISIJ Int., 1998, vol. 38, pp. 775–77.

H. Zhang, M.S. Yuan, N.M. Wen, and G.P. Cheng: Corros. Prot., 2002, vol. 23, pp. 436–40.

A. Besseyrias, F. Dalard, J.J. Rameau, and H. Baudin: Corros. Sci., 1995, vol. 37, pp. 587–95.

M.S. Oh, S.H. Kim, J.S. Kim, J.W. Lee, J.H. Shon, and Y.S. Jin: Met. Mater. Int., 2016, vol. 22, pp. 26–33.

J.W. Lee, B.R. Park, S.Y. Oh, D.W. Yun, J.K. Hawang, and M.S. Oh: Corros. Sci., 2019, vol. 160, 108170.

Acknowledgments

Financial support from the National Nature Science Foundation of China (Grant Nos. 51871030 and 51971039), and a project funded by Jiangsu Province Postgraduate Research and Practice Innovation (KYCX21-2800).

Conflict of interest

The authors report no declarations of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Z., Peng, H., Xie, A. et al. Effect of KCl–ZnCl2 Ball-Milling Fluxing on Microstructure and Corrosion of Iron Ingot Hot-Dip Zinc Coating. Metall Mater Trans A 54, 2744–2758 (2023). https://doi.org/10.1007/s11661-023-07051-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07051-7