Abstract

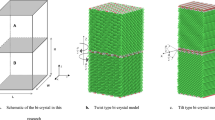

During deformation of bulk polycrystalline materials, misorientation develops due to plastic deformation within grains and additionally due to mismatch in the deformation of adjacent grains across grain boundaries. We have carried out incremental deformation of pure copper and studied misorientation development (Kernel Average Misorientation, KAM) near specific boundaries as a function of strain based on Electron Backscatter Diffraction (EBSD) measurements. To analyse misorientation variation within grains and near boundaries, we propose a novel method, section partitioning, which gives more representative measurements of misorientation as a function of distance from grain boundary. We find three kinds of behaviour near boundaries in terms of KAM: (i) lower than, (ii) intermediate between and (iii) higher than in-grain sections on either side of boundary. We also show that Grain Reference Orientation Deviation shows the best correlation with changes in the boundary character that occur as a result of deformation. Further we have performed molecular dynamics (MD) simulations of deformation of twinned crystals of copper. These results are used to qualitatively understand the misorientation development that we see in deformed samples. Our results highlight that similar Σ3 boundaries could show differences in misorientation development after deformation—and these are related to variations in dislocation boundary interactions. These results suggest that models for polycrystal deformation must incorporate such heterogeneous behaviour of boundaries.

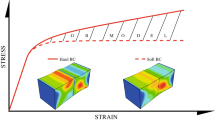

Graphical Abstract

Similar content being viewed by others

References

K. Konopka, J. Mizera, and J.W. Wyrzykowski: J. Mater. Process. Technol., 2000, vol. 99, pp. 255–59.

X. Zhang, A. Mishra, H. Wang, M. Nastasi, J.D. Embury, T.E. Mitchell, R.G. Hoagland, and J.P. Hirth: Appl. Phys. Lett., 2004, vol. 84, pp. 1096–98.

Y.G. Zheng, J. Lu, H.W. Zhang, and Z. Chen: Scr. Mater., 2009, vol. 60, pp. 508–11.

A.J. Cao, Y.G. Wei, and S.X. Mao: Appl. Phys. Lett., 2007, vol. 90, pp. 1–4.

K.A. Afanasyev and F. Sansoz: Nano. Lett., 2007, vol. 7, pp. 2056–62.

Y.B. Wang, B. Wu, and M.L. Sui: Appl. Phys. Lett., 2008, vol. 93, pp. 1–4.

W.A.T. Clark, C.E. Wise, Z. Shen, and R.H. Wagoner: Ultramicroscopy, 1989, vol. 30, pp. 76–89.

J. Kacher, B.P. Eftink, B. Cui, and I.M. Robertson: Curr. Opin. Solid State Mater. Sci., 2014, vol. 18, pp. 227–43.

T. Malis and K. Tangri: Acta Metall., 1979, vol. 27, pp. 25–32.

J. Jiang, T.B. Britton, and A.J. Wilkinson: Acta Mater., 2013, vol. 61, pp. 7227–39.

J. Jiang, T.B. Britton, and A.J. Wilkinson: Philos. Mag. Lett., 2012, vol. 92, pp. 580–88.

R.K. Davies and V. Randle: Mater. Sci. Eng. A, 2000, vol. 283, pp. 251–65.

M. Kamaya, J.Q. da Fonseca, L.M. Li, and M. Preuss: Appl. Mech. Mater., 2007, vol. 7, pp. 173–79.

S. Subedi, R. Pokharel, and A.D. Rollett: Mater. Sci. Eng. A, 2015, vol. 638, pp. 348–56.

S. Scheriau and R. Pippan: Mater. Sci. Eng. A, 2008, vol. 493, pp. 48–52.

A.K. Veneva, M.R. Koblischka, X.L. Zeng, J. Schmauch, and U. Hartmann: J. Phys., 2018, vol. 1054, pp. 1–8.

B. Wu, A. Heidelberg, and J.J. Boland: Nat. Mater., 2005, vol. 4, pp. 525–29.

A. Cao, Y. Wei, and E. Ma: Phys. Rev. B, 2008, vol. 77, pp. 1–8.

H.D. Espinosa, B.C. Prorok, and B. Peng: J. Mech. Phys. Solids, 2004, vol. 52, pp. 667–89.

G. Dehm, T.J. Balk, H. Edongué, and E. Arzt: Microelectron. Eng., 2003, vol. 70, pp. 412–24.

L. Nicola, Y. Xiang, J.J. Vlassak, E. van der Giessen, and A. Needleman: J. Mech. Phys. Solids, 2006, vol. 54, pp. 2089–110.

P.J. Imrich, C. Kirchlechner, C. Motz, and G. Dehm: Acta Mater., 2014, vol. 73, pp. 240–50.

N.K. Aragon, J.D. Gravell, and I. Ryu: Acta Mater., 2022, vol. 223, pp. 1–21.

P.J. Imrich, C. Kirchlechner, and G. Dehm: Mater. Sci. Eng. A, 2015, vol. 642, pp. 65–70.

N. Kheradmand, H. Vehoff, and A. Barnoush: Acta Mater., 2013, vol. 61, pp. 7454–65.

S. Zaefferer, J. Kuo, Z. Zhao, M. Winning, and D. Raabe: Acta Mater., 2003, vol. 51, pp. 4719–35.

N.A. Bonasso, F. Wagner, S. Berbenni, and D.P. Field: Mater. Sci. Eng. A, 2012, vol. 548, pp. 56–63.

X. Zhao, C. Lu, A.K. Tieu, L. Pie, L. Zhang, L. Su, and L. Zhan: Mater. Sci. Eng. A, 2017, vol. 687, pp. 343–51.

X.X. Zhao, J. Wu, Y.L. Chiu, I.P. Jones, R. Gu, and A.H.W. Ngan: Scr. Mater., 2019, vol. 163, pp. 137–41.

C. Howard, D. Frazer, A. Lupinacci, S. Parker, R.Z. Valiev, C. Shin, B.W. Choi, and P. Hosemann: Mater. Sci. Eng. A, 2016, vol. 649, pp. 104–13.

L.L. Li, Z.J. Zhang, J. Tan, C.B. Jiang, R.T. Qu, P. Zhang, J.B. Yang, and Z.F. Zhang: Sci. Rep., 2015, vol. 5, pp. 1–8.

J. Guo, S. Amira, P. Gougeon, and X.G. Chen: Mater. Charact., 2011, vol. 62, pp. 865–77.

V. Randle, N. Hansen, and D.J. Jensen: Philos. Mag. A, 1996, vol. 73, pp. 265–82.

N.I. Thiruselvam, R. Jeyaraam, S.J. Subramanian, and S. Sankaran: Materials, 2021, vol. 18, pp. 1–8.

I. Ryu, W.D. Nix, and W. Cai: Acta. Mater., 2013, vol. 61, pp. 3233–41.

M.M. Nowell and S.I. Wright: Ultramicroscopy, 2005, vol. 103, pp. 41–58.

N.P. Kryuchkov, S.O. Yurchenko, Y.D. Fomin, E.N. Tsiok, and V.N. Ryzhov: Soft Matter, 2018, vol. 14, pp. 2152–62.

A. Stukowski: Model. Simul Mat. Sci. Eng., 2010, vol. 18, pp. 1–8.

L. Ward, A. Agrawal, K. M. Flores, and W. Windl: arXiv:1209.0619, 2012, pp. 1–26.

G. Kamalakshi, P. Pant, and M.P. Gururajan: Comput. Mater. Sci., 2022, vol. 203, pp. 1–1.

M.N. Gussev and K.J. Leonard: J. Nucl. Mater., 2019, vol. 517, pp. 45–56.

C. Schayes, J. Bouquerel, J.B. Vogt, F. Palleschi, and S. Zaefferer: Mater. Charact., 2016, vol. 115, pp. 61–70.

S.I. Wright, S. Suzuki, and M.M. Nowell: JOM, 2016, vol. 68, pp. 2730–36.

K. Fujiyama, K. Mori, D. Kaneko, H. Kimachi, T. Saito, R. Ishii, and T. Hino: Int. J. Pres. Ves. Pip., 2009, vol. 86, pp. 570–7.

L. Hua, X. Hu, and X. Han: Mater. Des., 2020, vol. 196, pp. 1–26.

J. Wang, G. Chen, S. Huang, H. Zhang, Q. Chen, C. Zhang, and Z. Du: Int. J. Mech. Sci., 2022, vol. 218, pp. 1–2.

Z. Li, Y.C. Lin, L. Zhang, J. Zheng, J. Zhao, R. Wang, and Z. Jiang: Int. J. Mech. Sci., 2022, vol. 231, pp. 1–1.

S.V. Boxel, M. Seefeldt, B. Verlinden, and P.V. Houtte: Mater. Sci. Forum, 2005, vol. 495, pp. 1025–30.

Y. Wadamori, K. Hirayama, H. Fujiwara, T. Uenoya, and H. Miyamoto: J. Jpn. I. Met. Mater., 2013, vol. 77, pp. 348–52.

Y. Takayama and J.A. Szpunar: Mater. Trans., 2004, vol. 45, pp. 2316–25.

S.I. Wright, M.M. Nowell, and D.P. Field: Microsc. Microanal., 2011, vol. 17, pp. 316–29.

A. Kundu, D.P. Field, and P.C. Chakraborti: Mater. Sci. Eng. A, 2020, vol. 773, pp. 2–11.

D.N. Githinji, S.M. Northover, P.J. Bouchard, and M.A. Rist: Metall. Mater. Trans. A, 2013, vol. 44, pp. 4150–67.

Y. Kim, P.A. Rad, J. Lee, G.H. Gu, M. Jang, O. Bouaziz, Y. Estrin, H. Kato, and H.S. Kim: Mater. Sci. Eng. A, 2022, vol. 835, pp. 1–6.

M. Kamaya: Mater. Charact., 2012, vol. 66, pp. 56–67.

M. Kamaya, K. Kubushiro, Y. Sakakibara, S. Suzuki, H. Morita, R. Yoda, D. Kobayashi, K. Yamagiwa, T. Nishiyoka, Y. Yamazaki, Y. Kamada, T. Hanada, and T. Ohtani: Mech. Eng. J., 2016, vol. 3, pp. 1–5.

A. Ma, F. Roters, and D. Raabe: Acta Mater., 2006, vol. 54, pp. 2181–94.

A. Ma, F. Roters, and D. Raabe: Int. J. Solids Struct., 2006, vol. 43(24), pp. 7287–303.

N. Pai, A. Prakash, I. Samajdar, and A. Patra: Int. J. Plast., 2022, vol. 156, 103360.

Z. Shen, R.H. Wagoner, and W.A.T. Clark: Scr. Metall., 1986, vol. 20, pp. 921–26.

M. Chassagne, M. Legros, and D. Rodney: Acta Mater., 2011, vol. 59, pp. 1456–63.

C.M. Kuo and C.S. Lin: Scr. Mater., 2007, vol. 57, pp. 667–70.

A. Rohatgi, K.S. Vecchio, and G.T. Gray: Metall. Mater. Trans. A, 2001, vol. 32, pp. 135–45.

Acknowledgments

The authors would like to thank Department of Science and Technology (DST), Government of India for funding this study through projects 14DST017, CRG/2019/005060. The authors would like to acknowledge FIST lab facility, National Facility of Texture & OIM and high performance computing facilities at IIT Bombay for carrying out experimental and simulations work.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Verma, S., Kamalakshi, G., Gururajan, M.P. et al. Misorientation Development at Σ3 Boundaries in Pure Copper: Experiments and MD Simulations. Metall Mater Trans A 54, 2656–2669 (2023). https://doi.org/10.1007/s11661-023-07045-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07045-5