Abstract

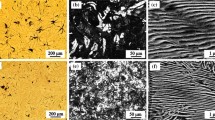

Advanced technologies and methods used in artificially tailoring the microstructure of Fe–C-based alloy hold the brilliant application prospect. Here, we demonstrate that the high magnetic field can decrease the flake graphite spacing, induce the disappearance of primary graphite, increase the eutectoid ferrite nucleation sites, and enhance the grain size distribution homogeneity of the eutectoid ferrite in the directionally solidified gray cast iron. These phenomena are mainly attributed to the magnetization behavior of the diffusion boundary layer and the different magnetizations between austenite and ferrite under the application of the magnetic field. Due to the magnetization of the diffusion boundary layer, the diffusion of C atoms is hindered, thus resulting in a decreased graphite spacing. The enhancement of the eutectoid ferrite nucleation is stemming from an increased eutectoid transformation temperature and the reduction of incubation time for the eutectoid transformation under the magnetic field. Further, the increased eutectoid transformation temperature also endows the decreased amount of the deformed ferrite grains and an amplified growth temperature range for ferrite, then the frequency of the low-angle misorientations reduces and that of the low-mobility CSL boundaries increases. In addition, because of the interaction among magnetic dipoles and the magnetocrystalline anisotropy, ferrite grains and graphite tend to align along the magnetic field direction. The current work is a successful demonstration of using the high magnetic field to tailor the solidification microstructure of gray cast iron, and paves a way for the development of the high-performance gray cast iron for industrial applications.

Graphical Abstract

Similar content being viewed by others

References

H. Yasuda, K. Morishita, N. Nakatsuka, T. Nishimura, M. Yoshiya, A. Sugiyama, K. Uesugi, and A. Takeuchi: Nat. Commun., 2019, vol. 10, p. 3183.

M. Gouné, F. Danoix, J. Ågren, Y. Bréchet, C.R. Hutchinson, M. Militzer, G. Purdy, S. Van Der Zwaag, and H. Zurob: Mat. Sci. Eng. R, 2015, vol. 92, pp. 1–38.

Y.C. Liu, D.J. Wang, F. Sommer, and E.J. Mittemeijer: Acta Mater., 2008, vol. 56, pp. 3833–842.

M. Trepczyńska-Łent, D. Boroński, and P. Maćkowiak: Mater. Sci. Eng. A, 2021, vol. 822, 141644.

D.M. Stefanescu, G. Alonso, P. Larrañaga, E. De La Fuente, and R. Suarez: Int. J. Metalcast., 2018, vol. 12, pp. 722–52.

U. Tewary, D. Paul, H.K. Mehtani, S. Bhagavath, A. Alankar, G. Mohapatra, S.S. Sahay, A.S. Panwar, S. Karagadde, and I. Samajdar: Acta Mater., 2022, vol. 226, 117660.

S.B. Wang, A.A. Kistanov, G. King, S. Ghosh, H. Singh, S. Pallaspuro, A. Rahemtulla, M. Somani, J. Kömi, W. Cao, and M. Huttula: Acta Mater., 2021, vol. 221, 117361.

D. Janicki, J. Górka, W. Kwaśny, W. Pakieła, and K. Matus: Materials, 2020, vol. 13, p. 1174.

L. Morsdorf, E. Emelina, B. Gault, M. Herbig, and C.C. Tasan: Acta Mater., 2021, vol. 205, 116521.

H.T. Zhao and E.J. Palmiere: Mater. Charact., 2019, vol. 158, 109990.

J.R. Gao, M.K. Han, A. Kao, K. Pericleous, D.V. Alexandrov, and P.K. Galenko: Acta Mater., 2016, vol. 103, pp. 184–91.

P.F. Jiang, J.T. Wang, L. Hou, Y. Fautrelle, and X. Li: J. Mater. Sci. Technol., 2020, vol. 50, pp. 86–91.

Z.Y. Lu, Y. Fautrelle, Z.M. Ren, and X. Li: Sci. Rep., 2018, vol. 8, p. 10641.

Y. Watanabe, R. Kobayashi, Y. Mitsui, R.Y. Umetsu, and K. Koyama: J. Alloys Compd., 2021, vol. 887, 161310.

C.S. Lou, T. Liu, M. Dong, C. Wu, J.G. Shao, and Q. Wang: J. Magn. Magn. Mater., 2017, vol. 424, pp. 365–70.

M. Veligatla, C. Titsch, W.G. Drossel, C.J. Garcia-Cervera, and P. Müllner: Acta Mater., 2020, vol. 186, pp. 389–95.

D.E. Laughlin: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 2555–569.

Y.P. Zeng, T. Mittnacht, W. Werner, Y. Du, D. Schneider, and B. Nestler: Acta Mater., 2022, vol. 225, 117595.

T. Kakeshita, T. Saburi, K. Kindo, and S. Endo: Jpn. J. Appl. Phys., 1997, vol. 36, p. 7083.

T. Kakeshita, K. Shimizu, S. Funada, and M. Date: Acta Metall., 1985, vol. 33, pp. 1381–389.

V.M. Schastlivtsev, Y.V. Kaletina, E.A. Fokina, and D.A. Mirzaev: Met. Sci. Heat Treat., 2016, vol. 58, pp. 247–53.

H. Ohtsuka: Sci. Technol. Adv. Mater., 2008, vol. 9, 013004.

M. Enomoto, G.H. Zhang, and K.M. Wu: Solid State Phenom., 2011, vol. 172–174, pp. 362–71.

X.J. Hao and H. Ohtsuka: Mater. Trans., 2004, vol. 45, pp. 2622–625.

S. Rivoirard, F. Gaucherand, E. Beaugnon, O. Bouaziz, and E. Pinto Da Costa: Metall. Res. Technol., 2005, vol. 102, pp. 393–97.

Y. Mitsui, Y. Ikehara, K. Takahashi, S. Kimura, G. Miyamoto, T. Furuhara, K. Watanabe, and K. Koyama: J. Alloys Compd., 2015, vol. 632, pp. 251–55.

T. Kakeshita and T. Fukuda: J. Phys., 2009, vol. 156, 012012.

T. Koyama and H. Onodera: ISIJ Int., 2006, vol. 46, pp. 1277–282.

G.M. Ludtka, R.A. Jaramillo, R.A. Kisner, D.M. Nicholson, J.B. Wilgen, G. Mackiewicz-Ludtka, and P.N. Kalu: Scripta Mater., 2004, vol. 51, pp. 171–74.

T. Garcin, S. Rivoirard, C. Elgoyhen, and E. Beaugnon: Acta Mater., 2010, vol. 58, pp. 2026–032.

J.J. Li and W. Liu: J. Magn. Magn. Mater., 2014, vol. 362, pp. 159–64.

A.M. Elwazri, P. Wanjara, and S. Yue: Mater. Sci. Technol., 2004, vol. 20, pp. 1469–473.

X. Li, Z.M. Ren, and Y. Fautrelle: Acta Mater., 2006, vol. 54, pp. 5349–360.

Z.P. Long, J.T. Wang, Y. Fautrelle, and X. Li: J. Alloys Compd., 2020, vol. 831, 154746.

X. Li, Y. Fautrelle, Z.M. Ren, Y.D. Zhang, and C. Esling: Acta Mater., 2010, vol. 58, pp. 2430–441.

K.A. Jackson and J.D. Hunt: Trans. Metal. Soc. AIME, 1966, vol. 236, p. 1129.

M. Shimotomai, K. Maruta, K. Mine, and M. Matsui: Acta Mater., 2003, vol. 51, pp. 2921–932.

Y.D. Zhang, C.S. He, X. Zhao, L. Zuo, and C. Esling: J. Magn. Magn. Mater., 2005, vol. 294, pp. 267–72.

K.C. Russell: Adv. Colloid Interface Sci., 1980, vol. 3–4, pp. 205–318.

H.B. Chang, Z.G. Li, T.Y. Hsu, Z.Y. Xu, and X.Y. Ruan: Acta Metall. Sin.-Engl., 1988, vol. 11, pp. 207–14.

Y.D. Zhang, C.S. He, X. Zhao, C. Esling, and L. Zuo: Adv. Eng. Mater., 2004, vol. 5, pp. 310–13.

R. Backofen, K.R. Elder, and A. Voigt: Phys. Rev. Lett., 2019, vol. 122, 126103.

C.M.B. Bacaltchuk, G.A. Castello-Branco, M. Ebrahimi, H. Garmestani, and A.D. Rollett: Scripta Mater., 2003, vol. 48, pp. 1343–347.

Y.D. Zhang, G. Vincent, N. Dewobroto, L. Germain, X. Zhao, L. Zuo, and C. Esling: J. Mater. Sci., 2005, vol. 40, pp. 903–08.

S. Kobayashi, R. Kobayashi, and T. Watanabe: Acta Mater., 2016, vol. 102, pp. 309–405.

T. Watanabe: Res. Mech., 1984, vol. 11, pp. 47–84.

Y.D. Zhang, C. Esling, J.S. Lecomte, C.S. He, X. Zhao, and L. Zuo: Acta Mater., 2005, vol. 53, pp. 5213–221.

D.M. Stefanescu, G. Alonso, P. Larrañaga, E. De La Fuente, and R. Suarez: Acta Mater., 2016, vol. 107, pp. 102–26.

K.S. Krishnan and N. Ganguli: Nature, 1937, vol. 139, pp. 155–56.

M.G. Sung, K. Hattori, and S. Asai: Mater. Des., 2009, vol. 30, pp. 387–90.

D.S. Kang, S.K. Seo, J.H. Kim, U.Y. Eom, and J.S. Roh: Res. Chem. Interned., 2014, vol. 40, pp. 2439–446.

Acknowledgments

This work was supported by National Natural Science Foundation of China (Nos. 51904183, 51690164, and 52130204) and Shanghai Science and Technology Committee Grant (19XD1401600 and 19010500300);

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Long, Z., Jiang, Q. et al. Effects of Magnetic Field on Microstructure, Phase Transformation and Ferrite Growth in Directionally Solidified Gray Cast Iron. Metall Mater Trans A 54, 2631–2644 (2023). https://doi.org/10.1007/s11661-023-07042-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07042-8