Abstract

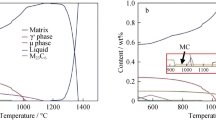

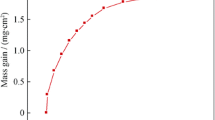

Ni23Cr18Mo superalloy is synthesized via microwave-assisted alumino-silicothermic reduction. Mixed powders of NiO, Cr2O3, MoO3, and different ratios of Al and Si are employed as the reactants. The thermodynamical considerations and chemical and microstructural characterization of the synthesized alloys were studied by Factsage™ software, induction coupled plasma, scanning electron microscopy equipped with energy-dispersive spectrometer, and X-ray diffraction. Thermodynamical calculations suggested that all the samples could be synthesized via combustion synthesis. Accordingly, the priority of the reduction of elements is Ni, Mo, and Cr, respectively. Results indicated that the NiCr2O4 complex is formed during the synthesis. The low activities of Ni and Cr in this compound have a negative effect on the recovery efficiency of these elements. Moreover, the lower recovery efficiency of Ni relative to Mo can be attributed to the lower melting point of MoO3 than NiO. However, results show that in the specimens with a reduction share of Al less than 20 pct, the synthesis does not occur due to the high-melting point and low-solid-state reactivity of Si. It was found that there is a dependency between Cr recovery and the presence of Al. With increasing the reduction share of Al from 40 to 100 pct, the recovery efficiency of Cr is enhanced by 3.3 times. Furthermore, excess Al significantly affects the recovery efficiency of Cr. However, adding excess Al to the precursors increases residual Si in the final alloy and encourages the formation of the Mo2Ni3Si intermetallic phase.

Similar content being viewed by others

References

I. Hemmati, V. Ocelík, and JTh.M. De Hosson: Phys. Procedia., 2013, vol. 41, pp. 302–11. https://doi.org/10.1016/j.phpro.2013.03.082.

P. Clook, NACE International, Denver, Colorado, 1996, NACE-96412,

C. Zheng, Z. Liu, Q. Liu, Y. Kong, and C. Liu: Coatings, 2022, vol. 12, pp. 421–40. https://doi.org/10.3390/coatings12040421.

A. Mishra: Acta Metall. Sin., 2017, vol. 30, pp. 306–18. https://doi.org/10.1007/s40195-017-0538-y.

A.K. Mishra and D.W. Shoesmith: Corrosion, 2014, vol. 70, pp. 721–30.

P. Jakupi, F. Wang, J.J. Noel, and D.W. Shoesmith: Corros. Sci., 2011, vol. 53, pp. 1670–679. https://doi.org/10.1016/j.corsci.2011.01.028.

R. Rosa, P. Veronesi, and C. Leonelli: Chem. Eng. Process., 2013, vol. 71, pp. 2–18. https://doi.org/10.1016/j.cep.2013.02.007.

A. Varma and J.P. Lebrat: Chem. Eng. Sci., 1992, vol. 47, pp. 2179–194. https://doi.org/10.1016/0009-2509(92)87034-N.

K. Morsi: J. Mater. Sci., 2012, vol. 47, pp. 68–92. https://doi.org/10.1007/s10853-011-5926-5.

K.C. Patil, M.S. Hegde, T. Rattan, and S.T. Aruna: Chemistry of Nanocrystalline Oxide Materials: Combustion Synthesis Properties and Applications, World Scientific, Singapore, 2008.

A.S. Mukasyan, C. Costello, K.P. Sherlock, D. Lafarga, and A. Varma: Sep. Purif. Technol., 2001, vol. 25, pp. 117–26. https://doi.org/10.1016/S1383-5866(01)00096-X.

B. Akgun, H.E. Camurlu, Y. Topkaya, and N. Sevinc: Int. J. Refract. Met. Hard Mater., 2011, vol. 29, pp. 601–607. https://doi.org/10.1016/j.ijrmhm.2011.04.005.

F. Maglia, U.A. Tamburini, G. Spinolo, and Z.A. Munir: J. Am. Ceram. Soc., 2000, vol. 83, pp. 1935–941. https://doi.org/10.1111/j.1151-2916.2000.tb01493.x.

A.G. Merzhanov: J. Mater. Chem., 2004, vol. 14, pp. 1779–786. https://doi.org/10.1039/B401358C.

A. Makino and C.K. Law: J. Am. Ceram. Soc., 1994, vol. 77, pp. 778–86. https://doi.org/10.1111/j.1151-2916.1994.tb05365.x.

A. Ashoka, A. Kumar, and F. Tarlochan: Int. J. Self-Propagating High-Temp. Synth., 2018, vol. 27, pp. 141–53. https://doi.org/10.3103/S1061386218030020.

V.N. Sanin and D.M. Ikornikov: Russ. J. Non-Ferr. Met., 2020, vol. 61, pp. 436–45. https://doi.org/10.3103/S1067821220040070.

A.A. Zaitsev, Z.A. Sentyurina, E.A. Levashov, Y.S. Pogozhev, V.N. Sanin, P.A. Loginov, and M.I. Petrzhik: Mater. Sci. Eng. A, 2017, vol. 690, pp. 463–72. https://doi.org/10.1016/j.msea.2016.09.075.

J. Feizabadi, J. Vahdati-Khaki, M. Haddad-Sabzevar, M. Sharifitabar, and S. Aliakbari-Sani: Mater Des., 2015, vol. 84, pp. 325–30. https://doi.org/10.1016/j.matdes.2015.06.138.

S. Grohmann, G. Langhans, A. Reindl, V. Sidarava, and M.F. Zaeh: J. Mater. Process Tech., 2020, vol. 282, p. 116637. https://doi.org/10.1016/j.jmatprotec.2020.116637.

A. Ghanbari, M. Sakaki, A. Faeghinia, MSh. Bafghi, and K. Yanagisawa: Bull. Mater. Sci., 2016, vol. 39, pp. 925–33. https://doi.org/10.1007/s12034-016-1229-4.

A. Dmitruk, K. Naplocha, M. Lagos, P. Egizabal, and J. Grzęda: Compos Theory Pract., 2018, vol. 18, pp. 241–44.

A. Chakraborti, N. Vast, and Y. Le Godec: Solid. State. Sci., 2020, vol. 104, pp. 1062–65. https://doi.org/10.1016/j.solidstatesciences.2020.106265.

P. Zhang, T. Xia, G. Zhang, and L. Yan: Mater. Sci. Forum., 2008, vol. 575, pp. 1086–92. https://doi.org/10.4028/www.scientific.net/MSF.575-578.1086.

M. Sharifitabar, J. Vahdati-Khaki, and M. Haddad-Sabzevar: Int. J. Self-Propag. High-Temp. Synth., 2014, vol. 47, pp. 93–101. https://doi.org/10.1016/j.ijrmhm.2014.07.006.

B.S.B. Reddy, K. Das, and S. Das: J. Mater. Sci., 2007, vol. 42, pp. 9366–378. https://doi.org/10.1007/s10853-007-1827-z.

W. Xi, S. Yin, and H. Lai: J. Mater. Process. Technol., 2003, vol. 137, pp. 1–4. https://doi.org/10.1016/S0924-0136(02)01050-6.

S. Liu, J. Zhou, Y. Li, and X. Zhang: Opt. Laser. Technol., 2019, vol. 113, pp. 365–73. https://doi.org/10.1016/j.optlastec.2018.12.044.

F. Kaya, M. Yetis, G. Ipek-Selimoglu, and B. Derin: Eng. Sci. Technol. Int. J., 2022, vol. 27, p. 101003. https://doi.org/10.1016/j.jestch.2021.05.007.

S.K. Mishra, S.K. Das, and V. Sherbacov: Compos. Sci. Technol., 2007, vol. 67, pp. 2447–453. https://doi.org/10.1016/j.compscitech.2006.12.017.

D. R. Gaskell, D. E. Laughlin, Introduction to the Thermodynamics of Materials, 6th Edition, CRC Press, Boca Raton, 2017, https://doi.org/10.1201/9781315119038

S.C. Kung: Metall. Trans. B, 1991, vol. 22, pp. 673–75. https://doi.org/10.1007/BF02679023.

H. Edris and D.G. McCartney: J. Mater. Sci., 1997, vol. 32, pp. 863–72. https://doi.org/10.1023/A:1018589230250.

R.L. Gordon and G.W. Harris: Nature, 1955, vol. 175, pp. 1135–136. https://doi.org/10.1038/1751135a0.

H.Y. Zhu, R. Gao, W.T. Jin, L.W. Qiu, and Z.L. Xue: Rare Met., 2018, vol. 37, pp. 621–24. https://doi.org/10.1007/s12598-015-0536-z.

R. Badrnezhad, F. Nasri, H. Pourfarzad, and S. Khadem-Jafari: Int. J. Hydrog. Energy, 2021, vol. 46, pp. 3821–832.

Y. Gui, C. Song, S. Wang, and D. Zhao: Mater. Res., 2016, vol. 31, pp. 66–75. https://doi.org/10.1557/jmr.2015.348.

J. Liu, J. Zhang, L. Deng, and G. Hao: Surf. Eng., 2019, vol. 35, pp. 59–65. https://doi.org/10.1080/02670844.2018.1460091.

Y.W. Xu and H.M. Wang: J. Alloys Compd., 2008, vol. 457, pp. 239–43. https://doi.org/10.1016/j.jallcom.2007.03.047.

Y.W. Xu and H.M. Wang: J. Alloys Compd., 2007, vol. 440, pp. 101–107. https://doi.org/10.1016/j.jallcom.2006.09.009.

K.P. Gupta: J. Ph. Equilib. Diffus., 2005, vol. 26, pp. 379–84. https://doi.org/10.1007/s11669-005-0095-3.

F. Liu, S. Yang, W. Sun, S. Guo, and Z. Hu: Int. J. Mod. Phys. B, 2009, vol. 23, pp. 1066–73. https://doi.org/10.1142/S0217979209060476.

P. Zhang, M. Li, H. Yan, J. Chen, Z. Yu, and X. Ye: J. Alloys Compd., 2019, vol. 785, pp. 984–1000. https://doi.org/10.1016/j.jallcom.2019.01.191.

M. Sakaki, A. Karimzadeh-Behnami, and M.S. Bafghi: Int. J. Refract. Hard. Met., 2014, vol. 44, pp. 142–47. https://doi.org/10.1016/j.ijrmhm.2014.02.003.

X.D. Cheng, J. Min, Z.Q. Zhu, and W.P. Ye: Metall. Mater., 2012, vol. 19, pp. 173–79. https://doi.org/10.1007/s12613-012-0534-1.

O. Muller, R. Roy, A.N.D. William, and B. White: J. Am. Ceram. Soc., 1967, vol. 51, pp. 693–99. https://doi.org/10.1111/j.1151-2916.1968.tb15930.x.

E.B. Rudnyi, E.A. Kaibicheva, and L.N. Sidorov: J. Chem. Thermodyn., 1990, vol. 22, pp. 623–32. https://doi.org/10.1016/0021-9614(90)90015-I.

S. W. Dean, The Influence of Gas Generation on Flame Propagation for Nano-Al Based Energetic Materials, Texas Tech University, 2008, http://hdl.handle.net/2346/10786

TYu. Kiseleva, A.A. Novakova, T.L. Talako, T.F. Grigoreva, and A.N. Falkova: Inorg. Mater., 2009, vol. 45, pp. 827–31. https://doi.org/10.1134/S002016850907022X.

C. Poupart: Control of Ignition Temperature in Hybrid Thermite-Intermetallic Reactive Systems, Christian Poupart, Ottawa, 2015, https://doi.org/10.20381/ruor-2833

J.J. Granier and M.L. Pantoya: Combust. Flame., 2004, vol. 138, pp. 373–83. https://doi.org/10.1016/j.combustflame.2004.05.006.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tahari, M., Vahdati Khaki, J. & Mirjalili, M. Microwave-Assisted Combustion Synthesis of Ni–Cr–Mo Superalloy Using Mixed Oxides: Mechanism and Thermodynamics Aspects. Metall Mater Trans A 54, 2605–2616 (2023). https://doi.org/10.1007/s11661-023-07038-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07038-4