Abstract

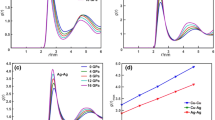

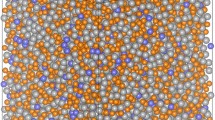

The liquid and the amorphous Al90Sm10 marginal metallic glassy alloy are investigated using Molecular Dynamics. The Al90Sm10 system consisting of 32,000 atoms is simulated under the constant number of atoms, pressure, and temperature (NPT) ensemble where the temperature and pressure are controlled via Nose–Hoover thermostat and barostat, respectively. The corresponding liquid model is initially held at 2300 K; then, the liquid is continuously cooled down to 300 K with a constant cooling rate of 1010 Ks−1, during which representative structures were obtained at each 200 K intervals. At every critical interval, radial distribution functions and structure factors are calculated. Local structural arrangements are analyzed using the Voronoi tessellation technique. These analyses indicate a chemically inhomogeneous liquid structure with large pure Al regions divided by a network of Sm-rich clusters, due to the high correlation of Al atoms at high temperatures. As the temperature of the liquid decreases, the amount of Al correlated with Sm in the first shell neighborhood increases. This makes the pure Al regions become smaller in size and widely separated. These pure Al regions in the amorphous solid are thought to be the possible nucleation sites for fcc-Al nanocrystals observed upon the devitrification of marginal metallic glasses.

Similar content being viewed by others

Change history

19 June 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11661-023-07102-z

References

W. Klement Jun, R.H. Willens, and P. Duwez: Nature, 1960, vol. 187, pp. 869–70. https://doi.org/10.1038/187869b0.

P. Chaudhari and D. Turnbull: Science, 1978, vol. 199, pp. 11–21. https://doi.org/10.1126/science.199.4324.11.

H.S. Chen: Rep. Prog. Phys., 1980, vol. 43, pp. 353–432. https://doi.org/10.1088/0034-4885/43/4/001.

A.L. Greer: Science, 1995, vol. 267, pp. 1947–53. https://doi.org/10.1126/science.267.5206.1947.

A.L. Greer and E. Ma: MRS Bull., 2007, vol. 32, pp. 611–19. https://doi.org/10.1557/mrs2007.121.

A.L. Greer: Mater. Today (Kidlington), 2009, vol. 12, pp. 14–22. https://doi.org/10.1016/S1369-7021(09)70037-9.

A. Inoue: Acta Mater., 2000, vol. 48, pp. 279–306. https://doi.org/10.1016/S1359-6454(99)00300-6.

A. Inoue and A. Takeuchi: Mater. Trans., 2002, vol. 43, pp. 1892–906. https://doi.org/10.2320/matertrans.43.1892.

W.L. Johnson: MRS Bull., 1999, vol. 24, pp. 42–56. https://doi.org/10.1557/S0883769400053252.

W.L. Johnson: JOM (1989), 2002, vol. 54, pp. 40–3. https://doi.org/10.1007/BF02822619.

J.F. Löffler: Intermetallics (Barking), 2003, vol. 11, pp. 529–40. https://doi.org/10.1016/S0966-9795(03)00046-3.

W.H. Wang, C. Dong, and C.H. Shek: Mater. Sci. Eng. R, 2004, vol. 44, pp. 45–89. https://doi.org/10.1016/j.mser.2004.03.001.

Y.Q. Cheng and E. Ma: Prog. Mater. Sci., 2011, vol. 56, pp. 379–473. https://doi.org/10.1016/j.pmatsci.2010.12.002.

A. Inoue, A. Kitamura, and T. Masumoto: J. Mater. Sci., 1981, vol. 16, pp. 1895–908. https://doi.org/10.1007/BF00540638.

Y. He, S.J. Poon, and G.J. Shiflet: Science, 1988, vol. 241, pp. 1640–42. https://doi.org/10.1126/science.241.4873.1640.

A. Inoue, K. Ohtera, A.-P. Tsai, and T. Masumoto: Jpn. J. Appl. Phys., 1988, vol. 27, pp. L280-282. https://doi.org/10.1143/jjap.27.l280.

T. Demirtaş and Y.E. Kalay: J. Non Cryst. Solids, 2013, vol. 378, pp. 71–8. https://doi.org/10.1016/j.jnoncrysol.2013.06.020.

Y.E. Kalay, L.S. Chumbley, and I.E. Anderson: Mater. Sci. Eng. A, 2008, vol. 490, pp. 72–80. https://doi.org/10.1016/j.msea.2008.02.032.

Y.E. Kalay, I. Kalay, J. Hwang, P.M. Voyles, and M.J. Kramer: Acta Mater., 2012, vol. 60, pp. 994–1003. https://doi.org/10.1016/j.actamat.2011.11.008.

Y.E. Kalay, L.S. Chumbley, and I.E. Anderson: J. Non-Cryst. Solids, 2008, vol. 354, pp. 3040–48. https://doi.org/10.1016/j.jnoncrysol.2007.12.006.

Y.E. Kalay, C. Yeager, L.S. Chumbley, M.J. Kramer, and I.E. Anderson: J. Non-Cryst. Solids, 2010, vol. 356, pp. 1416–24. https://doi.org/10.1016/j.jnoncrysol.2010.05.005.

Y.E. Kalay, L.S. Chumbley, M.J. Kramer, and I.E. Anderson: Intermetallics, 2010, vol. 18, pp. 1676–82. https://doi.org/10.1016/j.intermet.2010.05.005.

M. Ovun, M.J. Kramer, and Y.E. Kalay: J. Non Cryst. Solids, 2014, vol. 405, pp. 27–32. https://doi.org/10.1016/j.jnoncrysol.2014.08.037.

N. Wang, Y.E. Kalay, and R. Trivedi: Acta Mater., 2011, vol. 59, pp. 6604–19. https://doi.org/10.1016/j.actamat.2011.07.015.

T.B. Massalski, J.L. Murray, L.H. Bennett, and H. Baker: Binary alloy phase diagrams, ASM International, Ohio, 1986.

A. Inoue: Mater. Trans. JIM, 1995, vol. 36, pp. 866–75. https://doi.org/10.2320/matertrans1989.36.866.

A. Inoue: Prog. Mater. Sci., 1998, vol. 43, pp. 365–520. https://doi.org/10.1016/S0079-6425(98)00005-X.

C. Yildirim, M. Kutsal, R.T. Ott, M.F. Besser, M.J. Kramer, and Y.E. Kalay: Mater. Des., 2016, vol. 112, pp. 479–84. https://doi.org/10.1016/j.matdes.2016.09.060.

T.H. Ulucan, I. Kalay, and Y.E. Kalay: Metall. Mater. Trans. A, 2021, vol. 52, pp. 700–10. https://doi.org/10.1007/s11661-020-06111-6.

H.Y. Hsieh, T. Egami, Y. He, S.J. Poon, and G.J. Shiflet: J. Non-Cryst. Solids, 1991, vol. 135, pp. 248–54. https://doi.org/10.1016/0022-3093(91)90427-8.

Y. Sun, Y. Zhang, F. Zhang, Z. Ye, Z. Ding, C.-Z. Wang, and K.-M. Ho: J. Appl. Phys., 2016, vol. 120, p. 015901. https://doi.org/10.1063/1.4955223.

Y. Sun, F. Zhang, L. Yang, H. Song, M.I. Mendelev, C.-Z. Wang, and K.-M. Ho: Phys. Rev. Mater., 2019, vol. 3, p. 023404. https://doi.org/10.1103/PhysRevMaterials.3.023404.

J. Wang, A. Agrawal, and K. Flores: Acta Mater., 2019, vol. 171, pp. 163–69. https://doi.org/10.1016/j.actamat.2019.04.001.

M.-H. Yang, B. Cai, Y. Sun, F. Zhang, Y.-F. Wang, C.-Z. Wang, and K.-M. Ho: Phys. Rev. Mater., 2019, vol. 3, p. 125602. https://doi.org/10.1103/PhysRevMaterials.3.125602.

D. Choudhuri and B.S. Majumdar: Materialia, 2020, vol. 12, p. 100816. https://doi.org/10.1016/j.mtla.2020.100816.

S. Plimpton: J. Comput. Phys., 1995, vol. 117, pp. 1–9. https://doi.org/10.1006/jcph.1995.1039.

A.P. Thompson, S.J. Plimpton, and W. Mattson: J. Chem. Phys., 2009, vol. 131, p. 154107. https://doi.org/10.1063/1.3245303.

A.P. Thompson, H.M. Aktulga, R. Berger, D.S. Bolintineanu, W.M. Brown, P.S. Crozier, P.J. in ‘t Veld, A. Kohlmeyer, S.G. Moore, T.D. Nguyen, R. Shan, M.J. Stevens, J. Tranchida, C. Trott, and S.J. Plimpton: Comput. Phys. Commun., 2022, vol. 271, p. 108171. https://doi.org/10.1016/j.cpc.2021.108171.

M.I. Mendelev, F. Zhang, Z. Ye, Y. Sun, M.C. Nguyen, S.R. Wilson, C.Z. Wang, and K.M. Ho: Model. Simul Mat. Sci. Eng., 2015, vol. 23, p. 045013. https://doi.org/10.1088/0965-0393/23/4/045013.

S. Nosé: J. Chem. Phys., 1984, vol. 81, pp. 511–19. https://doi.org/10.1063/1.447334.

W.G. Hoover: Phys. Rev. A, 1985, vol. 31, pp. 1695–97. https://doi.org/10.1103/PhysRevA.31.1695.

T.E. Faber and J.M. Ziman: Philos. Mag., 1965, vol. 11, pp. 153–73. https://doi.org/10.1080/14786436508211931.

E. Prince: International tables for crystallography: mathematical, physical and chemical tables, International Union of Crystallography, Chester, 2006. https://doi.org/10.1107/97809553602060000103.

C.H. Rycroft: Chaos, 2009, vol. 19, p. 041111. https://doi.org/10.1063/1.3215722.

J. Park and Y. Shibutani: Mater. Trans., 2006, vol. 47, pp. 2904–09. https://doi.org/10.2320/matertrans.47.2904.

J.M. Haile: Molecular dynamics simulation: elementary methods, Wiley, Hoboken, 1992.

T. Egami and S. Billinge: Underneath the bragg peaks: structural analysis of complex materials. Pergamon materials series, Elsevier Science, Amsterdam, 2003.

S.P. Pan, J.Y. Qin, W.M. Wang, and T.K. Gu: Phys. Rev. B, 2011, vol. 84, p. 092201. https://doi.org/10.1103/PhysRevB.84.092201.

K. Zhang, H. Li, L. Li, and X.F. Bian: Appl. Phys. Lett., 2013, vol. 102, p. 071907. https://doi.org/10.1063/1.4793187.

Y.-C. Liang, R.-S. Liu, Y.-F. Mo, H.-R. Liu, Z.-A. Tian, Q.-Y. Zhou, H.-T. Zhang, L.-L. Zhou, Z.-Y. Hou, and P. Peng: J. Alloys Compd., 2014, vol. 597, pp. 269–74. https://doi.org/10.1016/j.jallcom.2014.01.052.

H. Tanaka: Eur. Phys. J. E, 2012, vol. 35, p. 113. https://doi.org/10.1140/epje/i2012-12113-y.

S.Y. Wang, C.Z. Wang, M.Z. Li, L. Huang, R.T. Ott, M.J. Kramer, D.J. Sordelet, and K.M. Ho: Phys. Rev. B, 2008, vol. 78, p. 184204. https://doi.org/10.1103/PhysRevB.78.184204.

S.R. Elliott: Nature, 1991, vol. 354, pp. 445–52. https://doi.org/10.1038/354445a0.

Q. Jingyu, B. Xiufang, S.I. Sliusarenko, and W. Weimin: J. Phys. Condens. Matter., 1998, vol. 10, pp. 1211–18. https://doi.org/10.1088/0953-8984/10/6/004.

M. Maret, T. Pomme, A. Pasturel, and P. Chieux: Phys. Rev. B, 1990, vol. 42, pp. 1598–604. https://doi.org/10.1103/PhysRevB.42.1598.

M. Sakata, N. Cowlam, and H.A. Davies: J. Phys., 1979, vol. 9, pp. L235-240. https://doi.org/10.1088/0305-4608/9/12/001.

S. Trady, M. Mazroui, A. Hasnaoui, and K. Saadouni: J. Non Cryst. Solids, 2016, vol. 443, pp. 136–42. https://doi.org/10.1016/j.jnoncrysol.2016.04.004.

G. Voronoi: J. Reine Angew. Math., 1908, vol. 1908, pp. 198–287. https://doi.org/10.1515/crll.1908.134.198.

J. Hwang, Z.H. Melgarejo, Y.E. Kalay, I. Kalay, M.J. Kramer, D.S. Stone, and P.M. Voyles: Phys. Rev. Lett., 2012, vol. 108, p. 195505. https://doi.org/10.1103/PhysRevLett.108.195505.

G.B. Bokas, L. Zhao, J.H. Perepezko, and I. Szlufarska: Scripta Mater., 2016, vol. 124, pp. 99–102. https://doi.org/10.1016/j.scriptamat.2016.06.045.

Q. Zhang, J. Li, X. Hu, S. Tang, Z. Wang, and J. Wang: J. Non Cryst. Solids, 2022, vol. 588, p. 121637. https://doi.org/10.1016/j.jnoncrysol.2022.121637.

S. Mishra and S. Pal: J. Non Cryst. Solids, 2018, vol. 500, pp. 249–59. https://doi.org/10.1016/j.jnoncrysol.2018.08.006.

H. Tanaka: J. Phys. Condens. Matter, 2003, vol. 15, pp. L491-498. https://doi.org/10.1088/0953-8984/15/31/102.

D.B. Miracle: Nat. Mater., 2004, vol. 3, pp. 697–702. https://doi.org/10.1038/nmat1219.

H.W. Sheng, W.K. Luo, F.M. Alamgir, J.M. Bai, and E. Ma: Nature, 2006, vol. 439, pp. 419–25. https://doi.org/10.1038/nature0442.

J. Ding, Y. Cheng, and E. Ma: Acta Mater., 2013, vol. 61, pp. 3130–40. https://doi.org/10.1016/j.actamat.2013.02.004.

J. Ding, Y.-Q. Cheng, and E. Ma: Acta Mater., 2014, vol. 69, pp. 343–54. https://doi.org/10.1016/j.actamat.2014.02.005.

Acknowledgments

This material is based upon work supported by the Air Force Office of Scientific Research under Award Number FA9550-20-1-0261. The numerical calculations reported in this study were partially performed at TUBITAK ULAKBIM, High Performance and Grid Computing Center (TRUBA resources).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sarıtürk, D., Kalay, Y.E. A Molecular Dynamics Study on the Local Structure of Al90Sm10 Marginal Metallic Glass and Liquid. Metall Mater Trans A 54, 2320–2328 (2023). https://doi.org/10.1007/s11661-023-07015-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07015-x