Abstract

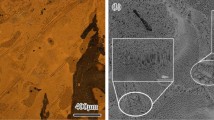

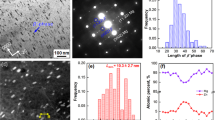

Micro-grain K447A superalloy with grain refined to 54 μm and yield strength up to 1022 MPa has been successfully fabricated in this work, whose strength is 200 MPa higher than that of conventional casting K447A. Owing to the bimodal distribution of γ′, two dislocation mechanisms act simultaneously at the initial stage of plastic deformation. That is, dislocations cut γ′ with radius less than 100 nm but bypass γ′ over 100 nm. Based on the deformation mechanisms of γ′ with different sizes, a frequency-weighted precipitation strengthening calculation method has been proposed to predict the contribution of precipitation strengthening accurately. Yield strength predicted by this method is in good agreement with experimental results with maximum error of 4.0 pct. Strength calculation indicates that micro-grain casting process improves the yield strength mainly by increasing the volume fraction of γ′ from 34.2 to 51.6 pct and reducing the grain size from 5 mm to 54 μm, compared with the conventional one.

Similar content being viewed by others

References

L.N. Li, X.F. Gong, C.S. Wang, Y.S. Wu, H.Y. Yu, H.J. Su, and L.Z. Zhou: Acta Metall. Sin. (Engl. Lett.), 2020, vol. 34, pp. 872–84.

H.Y. Bor, C.N. Wei, R.R. Jeng, and P.Y. Ko: Mater. Chem. Phys., 2008, vol. 109, pp. 334–41.

H.Y. Bor, C. Hsu, and C.N. Wei: Mater. Chem. Phys., 2004, vol. 84, pp. 284–90.

L.F. Norris, J.R. Brinegar, and L. Rozenberg: Superalloys Proc. Int. Symp., 5th, 1984, pp. 23–32.

P. Neil Agarwal and C.A. MacIntyre: SAE Trans., 1984, vol. 93, pp. 6–364.

H. Benson and M. Woulds: Superalloys Proc. Int. Symp., 5th, 1984, pp. 3–12.

J.H. Liao, H.Y. Bor, C.G. Chao, and T.F. Liu: Mater. Trans., 2010, vol. 51, pp. 810–17.

J.H. Liao, H.Y. Bor, C.G. Chao, and T.F. Liu: Mater. Trans., 2011, vol. 52, pp. 201–09.

P.P. Hu, Q.D. Gai, Q. Li, and X. Tang: Mater. Sci. Forum, 2016, vol. 849, pp. 549–56.

L. Liu, T.W. Huang, T.H. Xiong, A.M. Yang, Z.L. Zhao, R. Zhang, and J.S. Li: Superalloys 2004, Proc. Int. Symp., 10th, 2004, vol. 19. pp. 493–500.

T.H. Xiong, A.M. Yang, Y.P. Guo, W. Liu, and L. Liu: Sci. Technol. Adv. Mater., 2001, vol. 2, pp. 13–7.

C.N. Wei, H.Y. Bor, C.Y. Ma, and T.S. Lee: Mater. Chem. Phys., 2003, vol. 80, pp. 89–93.

B.N. Du, J.X. Yang, C.Y. Cui, and X.F. Sun: Mater. Sci. Eng. A, 2015, vol. 623, pp. 59–67.

Z.T. Gao, W. Guo, C.W. Zhang, and J.Q. Tan: Mater. Sci. Eng. A, 2017, vol. 682, pp. 156–63.

J.H. Xu, H. Gruber, R. Boyd, S. Jiang, R.L. Peng, and J.J. Moverare: Materialia, 2020, vol. 10, p. 100657.

M.R. Ahmadi, E. Povoden-Karadeniz, L. Whitmore, M. Stockinger, A. Falahati, and E. Kozeschnik: Mater. Sci. Eng. A, 2014, vol. 608, pp. 114–22.

K.L. Hou, M. Wang, M.Q. Ou, H.Z. Li, X.C. Hao, Y.C. Ma, and K. Liu: J. Mater. Sci. Technol., 2021, vol. 68, pp. 40–52.

B.D. Fu, K. Du, G.M. Han, C.Y. Cui, and J.X. Zhang: Mater. Lett., 2015, vol. 152, pp. 272–75.

J. Xie, J.J. Yu, X.F. Sun, T. Jin, and Y.H. Yang: Acta Metall. Sin., 2015, vol. 51, pp. 943–50.

P. Zhang, Y. Yuan, Z.H. Gao, Y.F. Gu, J. Li, J.B. Yan, X.F. Gong, J.T. Lu, X.B. Shi, and B.Q. Fu: J. Alloys Compd., 2021, vol. 862, p. 158478.

Z.W. Lian, J.J. Yu, X.F. Sun, H.R. Guan, and Z.Q. Hu: Mater. Sci. Eng. A, 2008, vol. 489, pp. 227–33.

R.W. Kozar, A. Suzuki, W.W. Milligan, J.J. Schirra, M.F. Savage, and T.M. Pollock: Metall. Mater. Trans. A, 2009, vol. 40, pp. 1588–603.

L.M. Tan, Y.P. Li, W.K. Deng, Y. Liu, F. Liu, Y. Nie, and L. Jiang: J. Alloys Compd., 2019, vol. 804, pp. 322–30.

C. Joseph, C. Persson, and M. Hörnqvist Colliander: Mater. Sci. Eng. A, 2017, vol. 679, pp. 520–30.

A.J. Goodfellow: Metall. Mater. Trans. A, 2018, vol. 34, pp. 1793–808.

D. Raynor and J.M. Slicock: Met. Sci. J., 1970, vol. 4, pp. 121–30.

A.J. Goodfellow, E.I. Galindo-Nava, C. Schwalbe, and H.J. Stone: Mater. Des., 2019, vol. 173, p. 107760.

E.I. Galindo-Nava, L.D. Connor, and C.M.F. Rae: Acta Mater., 2015, vol. 98, pp. 377–90.

A.J. Goodfellow, E.I. Galindo-Nava, K.A. Christofidou, N.G. Jones, C.D. Boyer, T.L. Martin, P.A.J. Bagot, M.C. Hardy, and H.J. Stone: Acta Mater., 2018, vol. 153, pp. 290–302.

Q.H. Fang, L. Li, J. Li, H.Y. Wu, Z.W. Huang, B. Liu, Y. Liu, and P.K. Liaw: J. Mech. Phys. Solids, 2019, vol. 122, pp. 177–89.

J.Y. Guédou, A.I. Epishin, T. Link, B. Fedelich, I.L. Svetlov, E.R. Golubovskiy, and J. Choné: MATEC Web Conf., 2014, vol. 14, p. 08003.

I. Sulak, K. Obrtlik, and L. Celko: Kovove Mater., 2016, vol. 54, pp. 471–81.

M.T. Kim, S.Y. Chang, and J.B. Won: Mater. Sci. Eng. A, 2006, vol. 441, pp. 126–34.

T. Yang, Y.L. Zhao, Z.B. Jiao, J. Wei, and J.X. Cai: Science, 2018, vol. 362, pp. 933–37.

K. Hou, M. Ou, M. Wang, X.C. Hao, Y.C. Ma, and K. Liu: Mater. Sci. Eng. A, 2021, vol. 820, p. 141588.

N. Zhou, C. Shen, M.J. Mills, J. Li, and Y.Z. Wang: Acta Mater., 2011, vol. 59, pp. 3484–497.

A. Vattré, B. Devincre, and A. Roos: Intermetallics, 2009, vol. 17, pp. 988–94.

P. Zhang, Y. Yuan, J. Li, Y.F. Xu, X.L. Song, and G.X. Yang: Mater. Sci. Eng. A, 2017, vol. 702, pp. 343–49.

F. Lu, S. Antonov, S. Lu, J.C. Zhang, L.F. Li, D. Wang, J. Zhang, and Q. Feng: Acta Mater., 2022, vol. 233, p. 117979.

X.P. Tan, J.L. Liu, and T. Jin: Mater. Sci. Eng. A, 2013, vol. 580, pp. 21–35.

T.M. Pollock and A.S. Argon: Acta Metall. Mater., 1992, vol. 40, pp. 1–30.

U. Bayerlein and H.G. Sockel: Mater. Sci. Eng. A, 1991, vol. 141, pp. 179–87.

K. Zhang, B. Holmedal, T. Mánik, and A. Saai: Int. J. Plast., 2019, vol. 114, pp. 144–60.

Q. Zhu, C.J. Wang, K. Yang, G. Chen, H.Y. Qin, and P. Zhang: J. Mater. Sci. Technol., 2020, vol. 40, pp. 146–57.

B. Clausen, T. Lorentzen, and T. Leffers: Acta Mater., 1998, vol. 46, pp. 3087–98.

M. Yoshinao, O. Shouichi, H. Noboru, Y. Masayoshi, and S. Tomoo: Trans. Jpn. Inst. Met., 1986, vol. 27, pp. 656–64.

H.A. Roth, C.L. Davis, and R.C. Thomson: Metall. Mater. Trans. A, 1997, vol. 28, pp. 1329–35.

Acknowledgments

The authors would like to acknowledge the financial support by Advanced High Temperature Structural Materials Laboratory in Beijing Institute of Aeronautical Materials.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Wang, X., Liu, R. et al. Improved Tensile Properties of Micro-grain Casting K447A Alloy. Metall Mater Trans A 54, 1710–1720 (2023). https://doi.org/10.1007/s11661-022-06894-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06894-w