Abstract

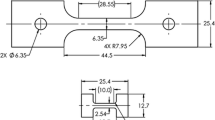

Recently proposed high-strength iron (Fe)/aluminum (Al) spot-forged joints, in which the thickness of the reaction layer is virtually intermetallic compound (IMC)-free in the mesoscopic region, are overlapping sheet materials for which the tensile strength of the interface is unknown. Thus, to measure the tensile strength of the interface, a direct tensile test was performed by sandwiching 1-mm-thick SPCC sheet material with A2024T4 extruded billets to create a forged member. Two types of SPCC were used, i.e., one polished with SiC #1000 abrasive and the other coated with approximately 2-μm-thick oxide scale to probe the effect of the contaminant layer on the strength; both displayed bonded interface (BI) fracture, with tensile strengths of 250 and 175 MPa, respectively. This welding method, which creates a newly formed surface, can be used for relatively high-strength bonding even in the presence of oxide scale. Fracture surface observations and chemical composition analyses revealed the fracture morphology of these materials. The fracture interface was roughly divided into two phases, Al matrix and Fe/Al, for the abrasive material, and three phases, Fe/Fe–O in addition to the two phases for the oxide scale-coated material. Only the Al matrix fracture was a ductile fracture surface, while the others were relatively brittle fracture surfaces. The area fraction of each fracture interface was determined by binarization, and the bond strength of each of phase was estimated according to the composite law assumed at the strain corresponding to the Fe/Al interface fracture. The tensile strength potential of a sound Fe/Al BI was estimated to exceed 339 MPa. The Vickers hardness of each material before and after welding was determined along with the microstructural changes; the hardness of SPCC increased significantly due to work hardening, while that of A2024T4 decreased due to thermal effects. The joint efficiency based on the A2024 member strength after welding was approximately 74 pct.

Similar content being viewed by others

References

S. Ohhama, T. Miyahara, M. Sayama, T. Hata, T. Kobayashi and T. Yahaba: SAE Technical Paper, 2013, 2013-01-0372

T. Gendo, K. Nishiguchi, and M. Asakawa: J. Jpn. Inst. Metals, 2006, vol. 70, pp. 870–73.

M. Alimadadi, M. Mahmoudiniya, M. Goodarzi, and S.M.A. Boutorabi: J. Adv. Join. Process., 2022, vol. 5, p. 100116.

N. Takeoka, T. Tsuchida, T. Matsuda, T. Ogura, R. Ohashi, and A. Hirose: J. Adv. Join. Process., 2022, vol. 5, p. 100112.

Y. Nakazawa: J. JILM, 2022, vol. 72, pp. 31–39.

T. Kobayashi, T. Iwase, and K. Maeda: KOBE Steel Eng. Rep., 2018, vol. 67, pp. 98–103.

K. Martinsen, S.J. Hu, and B.E. Carlson: CIRP Ann. Manuf. Technol., 2015, vol. 64, pp. 679–99.

J. Li, S. Muraishi, and S. Kumai: Mater. Trans., 2021, vol. 62, pp. 1184–93.

N. Kohlhorst, A. Kapil, Z. Chen, A. Vivek, T. Lee, J.C. Zhao, and G. Daehn: Metall. Mater. Trans. A, 2021, vol. 52, pp. 2795–2810.

S. Zhang, K. Gao, S.T. Hong, H. Ahn, Y. Choi, S. Lee, and H.N. Han: J. Mater. Res. Technol., 2021, vol. 20, pp. 271–82.

M. Du, W. Wang, X. Zhang, and J. Niu: Mater. Sci. Eng. A, 2022, vol. 20, p. 143746.

Y. Hu, Y. Zhang, G. Mi, C. Wang, W. Zhang, and Z. Zhang: J. Mater. Res. Technol., 2021, vol. 15, pp. 1896–1904.

H.S. Furuya, Y.T. Sato, Y.S. Sato, H. Kokawa, and Y. Tatsumi: Metall. Mater. Trans. A, 2018, vol. 49, pp. 527–36.

H. Yamagishi, S. Kakiuchi, and M. Sato: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 4659–68.

H. Yamagishi, M. Sato, and K. Kakiuchi: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 2154–62.

H. Yamagishi, Pat./Jan./PCT/JP2021/003018.

H. Yamagishi: Mater. Lett., 2020, vol. 278, 128412.

H. Yamagishi: Metall. Mater. Trans. A, 2021, vol. 52A, pp. 741–52.

H. Yamagishi: Mater. Lett., 2021, vol. 279, 130080.

H. Yamagishi: Mater. Trans., 2021, vol. 62, pp. 1576–82.

H. Yamagishi: Metall. Mater. Trans. A, 2022, vol. 53A, pp. 264–76.

Welding Handbook Committee, Other Welding Processes, in: R.L O'Brien (Eds), Welding handbook vol. 2, eighth ed., American Welding Society, FL,1991, pp. 917–18.

https://www.jfe-steel.co.jp/products/koukan/img/pdf/seizoukoutei_03.pdf/. Accessed 27 May 2022

N. Wang, T. Yamaguchi, and K. Nishio: J. Jpn. Inst. Met. Mater., 2013, vol. 77, pp. 259–67.

E. Fereiduni, M. Movahedi, A.H. Kokabi, and H. Najafi: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 1744–58.

Y. Huang, L. Wan, X. Si, T. Huang, X. Meng, and Y. Xie: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 295–99.

Y. Su, X. Hua, and Y. Wu: Mater. Sci. Eng. A, 2013, vol. 578, pp. 340–45.

Q.M. Nguyen and S.C. Huang: Materials, 2015, vol. 8, pp. 8246–54.

J. Yang, Y. Li, H. Zhang, W. Guo, D. Weckman, and N. Zhou: Metall. Mater. Trans. A, 2015, vol. 46A, pp. 5149–57.

J. Sun, Q. Yan, Z. Hi, and J. Huang: Mater. Des., 2016, vol. 90, pp. 468–77.

A. Sato, Y. Liu, T. Yasui, S. Yamaguchi and K. Hirosawa: Preprints of the National Meeting of JWS, vo.110, 2022, pp. 76–77.

S. Tomida, T. Nagae, and K. Nakata: Proc. Novel Mater., 2005, vol. 5, pp. 313–16.

Materials Strength Committee: Material strength, The Society of Materials Science Japan, Kyoto, 1994, p. 4.

N. Hasegawa, J. Arai, and T. Tanaka: J. Soc. Mater. Sci Jpn., 1990, vol. 39, pp. 859–63.

J.R. Davis: Aluminum and Aluminum Alloys, ASM International, OH, 1993, p. 71.

Acknowledgments

This work was supported by JSPS KAKENHI Grant Number JP20K05110.

Conflict of interest

The author declares that he has no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yamagishi, H. Tensile Strength and Fracture Morphology of Fe/Al Solid-State Bonding Interface Obtained by Forge Welding: Effect of Oxide Scale and Estimation of the Bond Strength of Each Phase. Metall Mater Trans A 53, 4064–4080 (2022). https://doi.org/10.1007/s11661-022-06816-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06816-w