Abstract

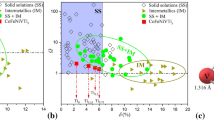

In the context of developing tungsten free cobalt alloys, the physical metallurgical properties of γ′ precipitate strengthened Co–Ti–V alloys were investigated. In this study, few alloys were cast and heat treated to study systematic effects on the properties. The addition of V to the Co–Ti system decreases γ′ solvus temperature, whereas it increases solidus temperature. The γ–γ′ lattice parameter misfit decreases with V addition. The γ′ precipitates have cuboidal with round corners morphology, and the extent of roundedness of corners increases with V addition. Density functional theory calculations were performed to understand the experimental observation of phase transformation temperatures, lattice misfit, and γ′ precipitate morphology. The calculations indicate that magnitude of the heat of formation of Co3(Ti,V) in the L12 crystal structure decreases with V addition. The γ–γ′ interfacial energy at 0 K is predicted to increase with V addition to the Co–Ti system.

Similar content being viewed by others

References

T.M. Pollock, J. Dibbern, M. Tsunekane, J. Zhu, and A. Suzuki: TMS JOM, 2010, vol. 62, pp. 58–63.

D.L. Douglass, V.S. Bhide, and E. Vineberg: Oxid. Met., 1981, vol. 16, pp. 29–79. https://doi.org/10.1007/BF00603744.

D. Coutsouradis, A. Davin, and M. Lamberigts: Mater. Sci. Eng., 1987, vol. 88, pp. 11–19. https://doi.org/10.1016/0025-5416(87)90061-9.

A.M. Beltran: Cobalt based alloys, in Superalloys, 2nd ed., C.T. Sims, N. Stoloff, and W.C. Hagel, eds., Wiley, New York, 1987, pp. 135–64.

A.V. Davydov, U.R. Kattner, D. Josell, J.E. Blendell, R.M. Waterstrat, A.J. Shapiro, and W.J. Boettinger: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2175–86. https://doi.org/10.1007/s11661-001-0193-8.

J. Sato, T. Omori, K. Oikawa, I. Ohnuma, R. Kainuma, and K. Ishida: Science, 2006, vol. 312, pp. 90–91. https://doi.org/10.1126/science.1121738.

S. Kobayashi, Y. Tsukamoto, T. Takasugi, H. Chinen, T. Omori, K. Ishida, and S. Zaefferer: Intermetallics, 2009, vol. 17, pp. 1085–89. https://doi.org/10.1016/j.intermet.2009.05.009.

T. Omori, K. Oikawa, J. Sato, I. Ohnuma, U.R. Kattner, R. Kainuma, and K. Ishida: Intermetallics, 2013, vol. 32, pp. 274–83. https://doi.org/10.1016/j.intermet.2012.07.033.

C.H. Zenk, S. Neumeier, H.J. Stone, and M. Göken: Intermetallics, 2014, vol. 55, pp. 28–39. https://doi.org/10.1016/j.intermet.2014.07.006.

H.J. Im, S.K. Makineni, B. Gault, F. Stein, D. Raabe, and P.-P. Choi: Scripta Mater., 2018, vol. 154, pp. 159–62. https://doi.org/10.1016/j.scriptamat.2018.05.041.

C.H. Zenk, I. Povstugar, R. Li, F. Rinaldi, S. Neumeier, D. Raabe, and M. Göken: Acta Mater., 2017, vol. 135, pp. 244–51. https://doi.org/10.1016/j.actamat.2017.06.024.

K.V. Vamsi, K.N. Goswami, K.S. Vinay, S.K. Verma, R. Balamuralikrishnan, N. Das, D. Banerjee, and S. Karthikeyan: MATEC Web Conf., 2014, vol. 14, p. 17007. https://doi.org/10.1051/matecconf/20141417007.

R.C. Reed: The Superalloys: Fundamentals and Applications, Cambridge University Press, New York, 2006.

Vanadium Cubic space group: Im-3m ICDD: 00-022-1058, Natl. Bur. Stand. (U.S.) Monogr. 25 (1971) 58.

Cobalt Cubic space group: Fm-3m ICDD: 00-015-0806, Natl. Bur. Stand. (U.S.) Monogr. 25 (1966) 10.

J.J. Ruan, C.P. Wang, C.C. Zhao, S.Y. Yang, T. Yang, and X.J. Liu: Intermetallics, 2014, vol. 49, pp. 121–31. https://doi.org/10.1016/j.intermet.2014.01.011.

Y. Liu, T. Takasugi, and O. Izumi: Metall. Mater. Trans. A, 1986, vol. 17A, pp. 1433–39. https://doi.org/10.1007/BF02650125.

R. Sailer, G. McCarthy, Titanium HCP space group: P63/mmc ICDD: 00-044-1294, ICDD. (1993).

L.J. Nagel, B. Fultz, and J.L. Robertson: J. Phase Equil., 1997, vol. 18(1), pp. 21–23. https://doi.org/10.1007/BF02646756.

J.-H. Xu, T. Oguchi, and A.J. Freeman: Phys. Rev. B, 1987, vol. 35(13), pp. 6940–43. https://doi.org/10.1103/PhysRevB.35.6940.

S. Neumeier, H.U. Rehman, J. Neuner, C.H. Zenk, S. Michel, S. Schuwalow, J. Rogal, R. Drautz, and M. Göken: Acta Mater., 2016, vol. 106, pp. 304–12. https://doi.org/10.1016/j.actamat.2016.01.028.

T. Takasugi and O. Izumi: Acta Metall., 1985, vol. 33, pp. 33–38. https://doi.org/10.1016/0001-6160(85)90216-0.

ASTM International, 2017, B311–17. https://doi.org/10.1520/B0311-17

ASTM International, 2011, E562–11. https://doi.org/10.1520/E0562-11

T.M. Smith, P. Bonacuse, J. Sosa, M. Kulis, and L. Evans: Mater. Charact., 2018, vol. 140, pp. 86–94. https://doi.org/10.1016/j.matchar.2018.03.051.

H.A. Kuhn, H. Biermann, T. Ungar, and H. Mughrabi: Acta Metall. Mater., 1991, vol. 39, pp. 2783–94. https://doi.org/10.1016/0956-7151(91)90095-I.

J. Rodríguez-Carvajal: Physica B, 1993, vol. 192, pp. 55–69. https://doi.org/10.1016/0921-4526(93)90108-I.

G. Kresse and J. Hafner: Phys. Rev. B, 1993, vol. 47(1), pp. 558–61. https://doi.org/10.1103/PhysRevB.47.558.

G. Kresse and J. Hafner: Phys. Rev. B, 1994, vol. 49(20), pp. 14251–69. https://doi.org/10.1103/PhysRevB.49.14251.

G. Kresse and J. Furthmueller: Phys. Rev. B, 1996, vol. 54(16), pp. 11169–86. https://doi.org/10.1103/PhysRevB.54.11169.

G. Kresse and J. Furthmueller: Comput. Mater. Sci., 1996, vol. 6, pp. 15–50. https://doi.org/10.1016/0927-0256(96)00008-0.

MedeA version 2.6.6, Materials Design Inc, Angel Fire, NM, 2009.

G. Kresse and D. Joubert: Phys. Rev. B, 1999, vol. 59(3), pp. 1758–75. https://doi.org/10.1103/PhysRevB.59.1758.

M. Methfessel and A.T. Paxton: Phys. Rev. B, 1989, vol. 40(6), pp. 3616–21. https://doi.org/10.1103/PhysRevB.40.3616.

J.P. Perdew, K. Burke, and M. Ernzerhof: Phys. Rev. Lett., 1996, vol. 77, pp. 3865–68. https://doi.org/10.1103/PhysRevLett.77.3865.

X.L. Liu, S.-L. Shang, Y.-J. Hu, Y. Wang, Y. Du, and Z.-K. Liu: Mater. Des., 2017, vol. 133, pp. 39–46. https://doi.org/10.1016/j.matdes.2017.07.028.

Y. Le Page and P. Saxe: Phys. Rev. B, 2002, vol. 65(10), p. 104104. https://doi.org/10.1103/PhysRevB.65.104104.

A. Zunger, S.-H. Wei, L.G. Ferreira, and J.E. Bernard: Phys. Rev. Lett., 1990, vol. 65, pp. 353–56. https://doi.org/10.1103/PhysRevLett.65.353.

S.R. Koneru: Modelling Chemistry, Structure and Properties of Concentrated Alloys at the Atomic Scale, Indian Institute of Science Bangalore, Bangalore, 2019.

F. Wang, D. Ma, and A. Bührig-Polaczek: Mater. Character., 2017, vol. 127, pp. 311–16. https://doi.org/10.1016/j.matchar.2017.02.030.

S.K. Makineni, A. Samanta, T. Rojhirunsakool, T. Alam, B. Nithin, A.K. Singh, R. Banerjee, and K. Chattopadhyay: Acta Mater., 2015, vol. 97, pp. 29–40. https://doi.org/10.1016/j.actamat.2015.06.034.

D.A. Porter, K.E. Easterling, and M.Y. Sherif: Phase Transformations in Metals and Alloys, 3rd ed. CRC Press, Boca Raton, 2009, p. 258.

Y. Chen, C. Wang, J. Ruan, T. Omori, R. Kainuma, K. Ishida, and X. Liu: Acta Mater., 2019, vol. 170, pp. 62–74. https://doi.org/10.1016/j.actamat.2019.03.013.

F.L.R. Tirado, S. Taylor, and D.C. Dunand: Acta Mater., 2019, vol. 172, pp. 44–54. https://doi.org/10.1016/j.actamat.2019.04.031.

K.V. Vamsi and S. Karthikeyan: Scripta Mater., 2017, vol. 130, pp. 269–73. https://doi.org/10.1016/j.scriptamat.2016.11.039.

K.V. Vamsi: Planar Fault Energies in Geometrically Close Packed A3B Intermetallics, Indian Institute of Science Bangalore, Bangalore, 2018.

Y. Mishin: Acta Mater., 2004, vol. 52, pp. 1451–67. https://doi.org/10.1016/j.actamat.2003.11.026.

M.E. Thompson, C.S. Su, and P.W. Voorhees: Acta Metall. Mater., 1994, vol. 42, pp. 2107–22. https://doi.org/10.1016/0956-7151(94)90036-1.

U. Glatzel and M. Feller-Kniepmeier: Scripta Metall., 1989, vol. 23, pp. 1839–44. https://doi.org/10.1016/0036-9748(89)90468-7.

J. Gump, H. Xia, M. Chirita, R. Sooryakumar, M.A. Tomaz, and G.R. Harp: J. Appl. Phys., 1999, vol. 86, pp. 6005–09. https://doi.org/10.1063/1.371647.

R.W. Jackson, M.S. Titus, M.R. Begley, and T.M. Pollock: Surf. Coat. Technol., 2016, vol. 289, pp. 61–68. https://doi.org/10.1016/j.surfcoat.2015.12.083.

C. Woodward, A. van de Walle, M. Asta, and D.R. Trinkle: Acta Mater., 2014, vol. 75, pp. 60–70. https://doi.org/10.1016/j.actamat.2014.04.056.

I. Schmidt and D. Gross: J. Mech. Phys. Solids., 1997, vol. 45, pp. 1521–49. https://doi.org/10.1016/S0022-5096(97)00011-2.

S.V. Prikhodko, H. Yang, A.J. Ardell, J.D. Carnes, and D.G. Isaak: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2403–08. https://doi.org/10.1007/s11661-999-0248-9.

L. Zhu, H. Pan, J. Cheng, L. Xiao, J. Guo, and H. Ji: J. Alloys Compd., 2022, vol. 918, 165677. https://doi.org/10.1016/j.jallcom.2022.165677.

Acknowledgments

The authors thank Prof. S. Suwas and Prof. K. Chattopadhyay for providing access to the alloy melting and casting facility, AFMM, IISc Bangalore, for the electron microscope facility. A portion of the research was performed using facilities at CeNSE, funded by the Department of Information Technology, Govt. of India and located at Indian Institute of Science, Bangalore. SKV thanks Prof. T. A. Abinandanan for useful discussion, Prof. T. Ungar for guidance in misfit calculation, Prof. D. Banerjee for access to MIPAR software, and govt. of India for the Ph.D. scholarship.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Verma, S.K., Pramanik, A., Jyothsna, K. et al. Phase Transformation Temperatures, γ–γ′ Lattice Parameter Misfit, and γ′ Precipitate Morphology in Co–Ti–V Alloys. Metall Mater Trans A 53, 4011–4022 (2022). https://doi.org/10.1007/s11661-022-06806-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06806-y