Abstract

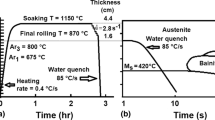

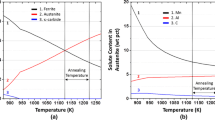

The effect of processing route on the microstructure and tensile behavior has been analyzed in a V-microalloyed medium-Mn steel containing 3.5 Al and 1.2 Si (in wt pct). To obtain four different microstructures, as hot-rolled (HR) band was divided into several parts and three of them were submitted to treatments consisting of annealing at 620 °C (HRA), warm rolling (WR), and warm rolling followed by annealing at 600 °C (WRA). Complex microstructures i.e., mixture of austenite, alpha ferrite, delta ferrite, and martensite in different amounts, were observed. Tensile tests show that the balance between these phases is the most important factor that contributes to the variation in the strength and ductility of this steel. At a given value of strain, the enhancement of strength observed in HR samples is related to the presence of a high amount of fresh martensite of up to 32 pct, while the higher total elongation to failure found in WR sample is associated to the presence of about 60 pct of retained austenite. Optimal mechanical properties have been achieved for the WRA sample with a yield strength of 808 MPa and an ultrahigh product of strength and elongation of approximately 59.5 GPa pct, which guarantee its usefulness for automotive applications.

Similar content being viewed by others

References

R. Kuziak, R. Kawalla, and S. Waengler: Arch. Civil Mech. Eng., 2008, vol. 8, pp. 103–17.

O. Bouaziz, H. Zurob, and M. Huang: Steel Res. Int., 2013, vol. 84, pp. 937–47.

D. Raabe, B. Sun, A. da Silva Kwiatkowski, B. Gault, H.W. Yen, K. Sedighiani, P. Thoudden Sukumar, I.R. SouzaFilho, S. Katnagallu, E. Jägle, P. Kürnsteiner, N. Kusampudi, L. Stephenson, M. Herbig, C.H. Liebscher, H. Springer, S. Zaefferer, V. Shah, S.L. Wong, C. Baron, M. Diehl, F. Roters, and D. Ponge: Metall. Mater. Trans. A, 2020, vol. 51A, pp. 5517–86.

T. Wang, J. Hu, and R.D.K. Misra: Mater. Sci. Eng., A, 2019, vol. 753, pp. 99–108.

J. Hu, J.M. Zhang, G.S. Sun, L.X. Du, Y. Liu, Y. Dong, and R.D.K. Misra: J. Mater. Sci., 2019, vol. 54, pp. 6565–78.

J. Hu, L.X. Du, W. Xu, J.H. Zhai, Y. Dong, Y.J. Liu, and R.D.K. Misra: Mater. Charact., 2018, vol. 136, pp. 20–28.

B. Hu, H. Luo, F. Yang, and H. Dong: J. Mater. Sci. Technol., 2017, vol. 33, pp. 1457–64.

B.C. de Cooman, P. Gibbs, S. Lee, and D.K. Matlock: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 2563–72.

N. Nakada, K. Mizutani, T. Tsuchiyama, and S. Takaki: Acta Mater., 2014, vol. 65, pp. 251–58.

Y.K. Lee and J. Han: Mater. Sci. Technol., 2015, vol. 31, pp. 843–56.

E. de Moor, D.K. Matlock, J.G. Speera, and M.J. Merwin: Scripta Mater., 2011, vol. 64, pp. 185–88.

J. Emo, P. Maugis, and A. Perlade: Comput. Mater. Sci., 2016, vol. 125, pp. 206–17.

W.S. Owen: Trans. Am. Soc. Met., 1954, vol. 46, pp. 812–29.

G. Miyamoto, J.C. Oh, K. Hono, T. Furuhara, and T. Maki: Acta Mater., 2007, vol. 55, pp. 5027–38.

H. Aydin, E. Essadiqi, I.H. Jung, and S. Yue: Mater. Sci. Eng. A, 2013, vol. 564, pp. 501–08.

R. Zhang, W.Q. Cao, Z.J. Peng, J. Shi, H. Dong, and C.X. Huang: Mater. Sci. Eng. A, 2013, vol. 583, pp. 84–88.

B.B. He, M. Wang, and M.X. Huang: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 2971–77.

D. Lee, J.K. Kim, S. Lee, K. Lee, and B.C. de Cooman: Mater. Sci. Eng. A, 2017, vol. 706, pp. 1–4.

J. Hu, L.X. Du, Y. Dong, Q.W. Meng, and R.D.K. Misra: Mater. Charact., 2019, vol. 152, pp. 21–35.

S. Lee, S. Lee, and B.C. de Cooman: Scripta Mater., 2011, vol. 65, pp. 225–28.

D.T. Pierce, J.A. Jiménez, J. Bentley, D. Raabe, C. Oskay, and J.E. Wittig: Acta Mater., 2014, vol. 68, pp. 238–53.

M. Pozuelo, J.E. Wittig, J.A. Jiménez, and G. Frommeyer: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 1826–34.

W. Hui, C. Shao, Y. Zhang, X. Zhao, and Y. Weng: Mater. Sci. Eng. A, 2017, vol. 707, pp. 501–10.

M.X. Huang and B.B. He: J. Mater. Sci. Technol., 2018, vol. 34, pp. 417–20.

H. Pan, H. Ding, and M. Cai: Mater. Sci. Eng. A, 2018, vol. 736, pp. 375–82.

Y. Zhang, W. Hui, J. Wang, C. Shao, and X. Zhao: Steel Res. Int., 2019, vol. 90, p. 1800412. https://doi.org/10.1002/srin.201800412.

H. Zheng, L. Fu, Z. Li, X. Ji, Q. Wang, W. Wang, and A. Shan: Mater. Today Commun., 2019, vol. 21, p. 100646. https://doi.org/10.1016/j.mtcomm.2019.100646.

B. Hu, X. Tu, H. Luo, and X. Mao: J. Mater. Sci. Technol., 2020, vol. 47, pp. 131–41.

B.B. He, B. Hu, H.W. Yen, G.J. Cheng, Z.K. Wang, H.W. Luo, and M.X. Huang: Science, 2017, vol. 357, pp. 1029–32.

D.J. Dyson: J. Iron Steel Inst., 1970, vol. 208, pp. 469–74.

L. Cheng, A. Btttger, T. de Keijser, and E. Mittemeijer: Scripta Mater., 1990, vol. 24, pp. 509–14.

Y. Li, W. Li, N. Min, W. Liu, and X. Jin: Acta Mater., 2017, vol. 139, pp. 96–108.

T. Swarr and G. Krauss: Metall. Trans. A, 1976, vol. 7A, pp. 41–48.

H.M. He: Mater. Sci. Technol., 2017, vol. 33, pp. 552–58.

S. Lee, S.J. Lee, S. Santhosh Kumar, K. Lee, and B.C.D. Cooman: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 3638–51.

S.J. Lee, J. Kim, S.N. Kane, and B.C. de Cooman: Acta Mater., 2011, vol. 59, pp. 6809–19.

S. Lee, J. Kim, S.J. Lee, and B.C. de Cooman: Scripta Mater., 2011, vol. 65, pp. 528–31.

Acknowledgments

This work was supported by the National Key R & D Program of China (Grant No. 2017YFB0304201), the Fundamental Research Funds for the Central Universities (Grant No. N180702012), and State Key Laboratory Opening Project of Northeastern University (Ref No. G20190006017).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, L., Xiao, N., Jia, T. et al. Effect of Processing Route on the Microstructure and Tensile Properties of an Al and Si-Bearing Medium-Mn TRIP Steel Microalloyed with V. Metall Mater Trans A 53, 3724–3735 (2022). https://doi.org/10.1007/s11661-022-06780-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06780-5