Abstract

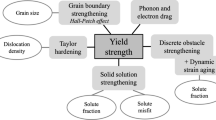

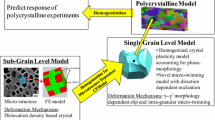

In the present study, tensile deformation behavior of a coarse-grained (> 1 mm) cast alloy 625 has been investigated by applying empirical and physics-based models. The experimental stress-strain data of the alloy at different deformation temperatures are acquired from uniaxial tensile testing up to 700 °C. The plastic strain region of the alloy’s flow stress (σ) curve shows a significant deviation from the traditional Holloman equation. Parallelly, a distinctive hump in the strain-hardening (θ) curve is also observed after the initial steep drop. Dislocation density-based phenomenological modeling is adopted to ascertain the mechanisms governing plastic deformation of the alloy. The hump in strain-hardening curve is related to the combined effects of low-stacking fault energy of the material and large size grains, which led to deform the material with a smooth transition from restricted single slip at onset of plastic deformation to duplex slip and finally to multiple slips at later stages. As the deformation progresses, this transition results in a smooth exponential drop in the dislocation mean-free path. Transition in slip activity is confirmed through SEM and TEM studies. Further, when the deformation temperature increases, there is an increase in the rate of dynamic recovery and the rate at which single- → multiple-slip transition attains. The microstructural studies of the tensile-fractured samples indicate that the carbide/matrix and carbide/grain boundary interfaces play a crucial role in crack nucleation and propagation during the deformation. Notch tensile testing revealed that introducing a stress raiser would localize the strain and can cause dislocations to glide with a lowered initial mean-free path on multiple-slip systems from the very beginning of plastic deformation.

Similar content being viewed by others

References

A. Di Gianfrancesco: Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants, 2017.

T.M. Pollock and S. Tin: J. Propuls. Power., 2006, vol. 22, pp. 361–74.

S. Floreen, G.E. Fuchs, and W.J. Yang: in Superalloys 718,625,706 and Various Derivatives, 1994, pp. 13–37.

H.L. Eiselstein and D.J. Tillack: in Superalloys 718,625 and Various Derivatives, 1991, pp. 1–14.

L.M. Suave, J. Cormier, P. Villechaise, A. Soula, Z. Hervier, D. Bertheau, and J. Laigo: Metall. Mater. Trans. A., 2014, vol. 45A, pp. 2963–82.

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee: in Superalloys 718,625,706 and Various Derivatives, 1997, pp. 367–78.

V. Shankar, K. Bhanu Sankara Rao, and S.L. Mannan: J. Nucl. Mater., 2001, vol. 288, pp. 222–32.

D. Liu, X. Zhang, X. Qin, and Y. Ding: Mater. Sci. Technol., 2017, vol. 33, pp. 1610–17.

C.A. Badrish, N. Kotkunde, G. Mahalle, S.K. Singh, and K. Mahesh: J. Mater. Eng. Perform., 2019, vol. 28, pp. 7537–53.

X. Wang, Y. Ding, Y. Gao, Y. Ma, J. Chen, and B. Gan: Mater. Sci. Eng. A., 2021, vol. 823, p. 141739.

Y. Gao, Y. Ding, J. Chen, J. Xu, Y. Ma, and X. Wang: Mater. Sci. Eng. A., 2019, vol. 767, p. 138361.

V. Shankar, M. Valsan, K.B.S. Rao, and S.L. Mannan: Metall. Mater. Trans. A., 2004, vol. 35A, pp. 3129–39.

P. Maj, J. Zdunek, J. Mizera, K.J. Kurzydlowski, B. Sakowicz, and M. Kaminski: Met. Mater. Int., 2017, vol. 23, pp. 54–67.

M.M. De Oliveira, A.A. Couto, G.F.C. Almeida, D.A.P. Reis, N.B. De Lima, and R. Baldan: Metals., 2019, vol. 9, p. 301.

X. Liu, J. Fan, P. Zhang, J. Xie, F. Chen, D. Liu, R. Yuan, B. Tang, H. Kou, and J. Li: J. Alloys Compd., 2021, vol. 869, p. 159342.

F. Yang, J. Hou, C. Wang, and L. Zhou: Trans. Nonferr. Met. Soc. China., 2021, vol. 31, pp. 426–37.

A.H.V. Pavan, R.L. Narayan, M. Swamy, K. Singh, and U. Ramamurty: Mater. Sci. Eng. A., 2020, vol. 793, p. 139811.

A.K. Godasu, U. Prakash, and S. Mula: J. Alloys Compd., 2020, vol. 844, p. 156200.

G.E. Dieter and D. Bacon: Mechanical Metallurgy, 3rd ed. McGraw-Hill Book Company, New York, 1988.

A.H. Cottrell: Dublin Philos. Mag. J. Sci., 1953, vol. 44, pp. 829–32.

P. Rodriguez: Bull. Mater. Sci., 1984, vol. 6, pp. 653–63.

M.C.C. In Sup Kim: Trans. Jpn. Inst. Met., 1987, vol. 28, pp. 205–12.

B. Max, J. San Juan, M.L. Nó, J.M. Cloue, B. Viguier, and E. Andrieu: Metall. Mater. Trans. A., 2018, vol. 49A, pp. 2057–68.

R.W. Hayes: Acta Metall., 1983, vol. 31, pp. 365–71.

D.C. Ludwigson: Metall. Trans., 1971, vol. 2, pp. 2825–28.

B.K. Choudhary, E. Isaac Samuel, K. Bhanu Sankara Rao, and S.L. Mannan: Mater. Sci. Technol., 2001, vol. 17, pp. 223–31.

R. Abbaschian and R.E. Reed-Hill: Physical Metallurgy Principles, 4th ed. Cengage Learning, Boston, 2009.

K. Levenberg: Q. Appl. Math., 1944, vol. 2, pp. 164–68.

N.P. Gurao and S. Suwas: Mater. Lett., 2013, vol. 99, pp. 81–85.

W.F. Hosford: The Mechanics of Crystals and Textured Polycrystals, Oxford University Press, New York, 1993.

C.L. Yang, Z.J. Zhang, T. Cai, P. Zhang, and Z.F. Zhang: Sci. Rep., 2015, vol. 5(1), pp. 1–7.

A. Rollett, F. Humphreys, G.S. Rohrer, and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2nd ed. Elsevier, Amsterdam, 2004.

H. Ding, H. Ding, D. Song, Z. Tang, and P. Yang: Mater. Sci. Eng. A., 2011, vol. 528, pp. 868–73.

M.C. Mcgrath, D.C. Van Aken, N.I. Medvedeva, and J.E. Medvedeva: Metall. Mater. Trans. A., 2013, vol. 44A, pp. 4634–43.

G.I. Taylor: Proc. R. Soc. Lond., 1934, vol. 145, pp. 362–87.

H. Mecking and U.F. Kocks: Acta Metall., 1981, vol. 29, pp. 1865–75.

Y. Estrin and L.P. Kubin: Acta Metall., 1986, vol. 34, pp. 2455–64.

F. Barlat, M.V. Glazov, J.C. Brem, and D.J. Lege: Int. J. Plast., 2002, vol. 18, pp. 919–39.

G.K. Batchelor: The Scientific Papers of Sir G.I.Taylor. Mechanics of Solids., Vol. 1. Cambridge University Press, Cambridge, 1958.

W. Mao: Front. Mater. Sci., 2016, vol. 10, pp. 335–45.

S. Mishra, M. Yadava, K.N. Kulkarni, and N.P. Gurao: Acta Mater., 2019, vol. 178, pp. 99–113.

C. Keller and E. Hug: Int. J. Plast., 2017, vol. 98, pp. 106–22.

M. Kamaya: Mater. Charact., 2012, vol. 66, pp. 56–67.

J.F. Baker and C.F. Tipper: Proc. Inst. Mech. Eng., 1956, vol. 170, pp. 65–93.

Acknowledgments

The authors acknowledge the funding by the Science and Engineering Research Board, Government of India, through Grant No. CRG/2019/000949 and the support of the material from MIDHANI LTD., Hyderabad, India. The authors are also thankful to the Head of the Metallurgical and Materials Engineering Department, IIT Roorkee, for permitting use of different experimental facilities.

Conflict of interest

The authors declare no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Godasu, A.K., Mishra, S., Prakash, U. et al. Tensile Deformation Modeling of a Homogenized Cast Alloy 625: Effects of Large Grain Size. Metall Mater Trans A 53, 2239–2258 (2022). https://doi.org/10.1007/s11661-022-06666-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06666-6