Abstract

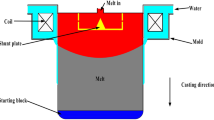

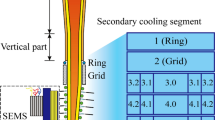

Due to the nonaxisymmetric feature of slabs, the macrotransport phenomena during direct chill (DC) casting are more complex than the macrotransport phenomena of round billets and are tightly associated with their dimensions, width-thickness ratio and even the structure of the shunt plate used to feed the melt to the slab edge. In the present research, aiming to find the desirable structure of the shunt plate and clarify how the form of the magnetic field (MF) affects the transport phenomena, a 3-D coupled mathematical model was set up and used to study the fluid flow, heat transfer and solidification characteristics during electromagnetic DC casting of a magnesium alloy slab with dimensions of 1200 mm (width) × 400 mm (thickness). The effects of the hole distribution of the shunt plate under MF or no MF and different forms of MF on the corresponding physical fields were studied systematically. The predicted results, including the Lorentz force distribution, macro-flow and temperature fields, cooling curve and sump depth, were presented and compared. The results indicated that reducing the holes facing the wide surface was helpful for obtaining desirable variations, such as more homogeneous melt flow and temperature fields, shallower sump depth and faster cooling rate. Using a specific out-of-phase pulsed magnetic field also promoted the above variations more than other forms of magnetic field.

Similar content being viewed by others

References

M. Duan, L. Luo, and Y. Liu: J. Alloys Compd., 2020, vol. 823, p. 153691.

D.G. Eskin, J. Zuidema, V.I. Savran, and L. Katgerman: Mater. Sci. Eng. A., 2004, vol. 384, pp. 232–44.

C. Zhu, Z.H. Zhao, Q.F. Zhu, G.S. Wang, X.D. Liu, Y. Bo Zuo, H.C. Dong, and G.W. Qin: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2021, vol. 52, pp. 3342–52.

V. Hatić, B. Mavrič, N. Košnik, and B. Šarler: Appl. Math. Model., 2018, vol. 54, pp. 170–88.

X.J. Wang, D.K. Xu, R.Z. Wu, X.B. Chen, Q.M. Peng, L. Jin, Y.C. Xin, Z.Q. Zhang, Y. Liu, X.H. Chen, G. Chen, K.K. Deng, and H.Y. Wang: J. Mater. Sci. Technol., 2018, vol. 34, pp. 245–47.

X.D. Liu, Q.F. Zhu, Y.B. Zuo, C. Zhu, Z.H. Zhao, and J.Z. Cui: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2019, vol. 50, pp. 5727–33.

Y.B. Zuo, M.X. Xia, S.M. Liang, Y. Wang, G.M. Scamans, and Z.Y. Fan: Mater. Sci. Technol., 2011, vol. 27, pp. 101–07.

Y. Tian, Z.L. Liu, X.Q. Li, L.H. Zhang, R.Q. Li, R.P. Jiang, and F. Dong: Ultrason. Sonochem., 2018, vol. 43, pp. 29–37.

X.R. Chen, Q.C. Le, X.B. Wang, Q.Y. Liao, and C.Y. Chu: Metals (Basel)., 2017, vol. 7, p. 173.

S.J. Guo, Q.C. Le, Z.H. Zhao, Z.J. Wang, and J.Z. Cui: Mater. Sci. Eng. A., 2005, vol. 404, pp. 323–29.

J.P. Park, M.G. Kim, U.S. Yoon, and W.J. Kim: J. Mater. Sci., 2009, vol. 44, pp. 47–54.

Z.W. Shao, Q.C. Le, Z.Q. Zhang, and J.Z. Cui: Mater. Des., 2011, vol. 32, pp. 4216–24.

X.R. Chen, Y.H. Jia, Q.Y. Liao, W.T. Jia, Q.C. Le, S.C. Ning, and F.X. Yu: J. Alloys Compd., 2019, vol. 774, pp. 710–20.

W.C. Duan, S.Q. Yin, W.H. Liu, J. Yang, Q.F. Zhu, L. Bao, P. Wang, J.Z. Cui, and Z.Q. Zhang: Int. J. Numer. Methods Heat Fluid Flow., 2021, vol. 31, pp. 829–57.

Y.H. Jia, J. Hou, H. Wang, Q.C. Le, Q. Lan, X.R. Chen, and L. Bao: J. Mater. Process. Technol., 2020, vol. 278, p. 116542.

H.M. Ji, T.J. Luo, C. Wang, J. Cui, and Y.S. Yang: Mater. Sci. Technol. (United Kingdom)., 2017, vol. 33, pp. 33–39.

W.C. Duan, J.X. Bao, W.H. Liu, Z.Q. Zhang, and J.Z. Cui: Int. J. Heat Mass Transf., 2020, vol. 162, p. 120353.

P. Jarry and M. Rappaz: Comptes Rendus Phys., 2018, vol. 19, pp. 672–87.

P. Barral, A. Bermúdez, M.C. Muñiz, M.V. Otero, P. Quintela, and P. Salgado: J. Mater. Process. Technol., 2003, vol. 142, pp. 383–99.

J.C. Álvarez-Hostos, A.D. Bencomo, E.S. Puchi-Cabrera, V.D. Fachinotti, B. Tourn, and J.C. Salazar-Bove: Eng. Anal. Bound. Elem., 2019, vol. 106, pp. 170–81.

J.M. Drezet and T. Pirling: J. Mater. Process. Technol., 2014, vol. 214, pp. 1372–78.

M. Hasan and L. Begum: Heat Mass Transf. Stoffuebertrag., 2016, vol. 52, pp. 789–803.

M. Hasan and L. Begum: J. Therm. Sci. Eng. Appl., 2015, vol. 7, p. 21008.

L. Begum and M. Hasan: Int. J. Heat Mass Transf., 2014, vol. 73, pp. 42–58.

L. Begum and M. Hasan: Appl. Math. Model., 2016, vol. 40, pp. 9029–51.

L. Begum and M. Hasan: Int. J. Therm. Sci., 2014, vol. 86, pp. 68–87.

L. Begum and M. Hasan: Numer. Heat Transf. Part A Appl., 2015, vol. 67, pp. 746–70.

S.Y. Shi, H. Hao, X.G. Zhang, C.F. Fang, S. Yao, and J.Z. Jin: Rare Met. Mater. Eng., 2009, vol. 38, pp. 203–08.

W.Y. Hu, Q.C. Le, Z.Q. Zhang, L. Bao, and J.Z. Cui: J. Magnes. Alloy., 2013, vol. 1, pp. 88–93.

M. Hasan and L. Begum: J. Magnes. Alloy., 2014, vol. 2, pp. 275–86.

M. Hasan and L. Begum: J. Magnes. Alloy., 2015, vol. 3, pp. 283–301.

O. Ben-David, A. Levy, B. Mikhailovich, and A. Azulay: Phys. Fluids., 2014, vol. 26, p. 097104.

B.E. Launder and B.I. Sharma: Lett. Heat Mass Transf., 1974, vol. 1, pp. 131–37.

M. Paliwal and I.H. Jung: Acta Mater., 2013, vol. 61, pp. 4848–60.

G.C. Nzebuka, M.A. Waheed, S.I. Kuye, and B.I. Olajuwon: Metall. Mater. Trans. B., 2019, vol. 50, pp. 866–80.

V.R. Voller and C. Prakash: Int. J. Heat Mass Transf., 1987, vol. 30, pp. 1709–19.

ANSYS Fluent User’s Guide, Release 18.0, 2017. Available online: http://www.ansys.com/products/fluids/

D.C. Weckman and P. Niessen: Metall. Trans. B., 1982, vol. 13B, pp. 593–602.

E.D. Tarapore: in Light Metals, P. G. Campbell, ed., TMS, Warrendale, PA, 1989, pp. 875–80.

C.J. Vreeman and F.P. Incropera: Int. J. Heat Mass Transf., 2000, vol. 43, pp. 687–704.

W.Y. Hu, Q.C. Le, Z.Q. Zhang, L. Bao, X. Liu, Z.W. Shao, and J.Z. Cui: Int. J. Cast Met. Res., 2016, vol. 29, pp. 228–35.

M.Y. Ha, H.G. Lee, and S.H. Seong: J. Mater. Process. Technol., 2003, vol. 133, pp. 322–39.

A.N. Turchin, M. Zuijderwijk, J. Pool, D.G. Eskin, and L. Katgerman: Acta Mater., 2007, vol. 55, pp. 3795–3801.

Acknowledgments

This research was financially supported by the National Key Research and Development Program of China (Grant No. 2021YFB3701004), the National Natural Science Foundation of China (Grant No. 51971054, 52171055) and the Fundamental Research Funds for the Central Universities (N2009006, N2107007).

Conflict of interest

All authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Nomenclature | |||

|---|---|---|---|

Latin symbols | |||

A | mushy zone constant (kg/(m3 s)) | X, Y, Z | wide direction, thickness direction, vertical direction |

\(\vec{B}\) | magnetic flux density vector (T) | ||

C | specific heat (J/(g K)) | x, y, z | coordinate value at wide direction, thickness direction, vertical direction |

C eff | equivalent specified heat (J/(g K)) | ||

D | extra dissipation term in k-equation | ||

d | secondary dendrite arm spacing (m) | ||

\(\vec{E}\) | electric field intensity vector (V/m) | Greek symbols | |

E | extra generation term in ε-equation | μ 0 | magnetic permeability |

\(\vec{f}\) | electromagnetic force (N/m3) | ε 0 | dielectric constant |

fl, fs | liquid fraction, solid fraction | ρ e | electric charge density (C/m2) |

f1, f1, fμ | constants used in low Reynolds k-ε | σ | electrical conductivity (S/m) |

fk, fcr | constants related to mushy zone | μ | laminar viscosity (Pa s) |

\(\vec{F}\) | mean electromagnetic force (N/m3) | μ T | turbulent viscosity (Pa s) |

FX, FY, FZ | Time-averaged electromagnetic force components in three directions (N/m3) | ρ | density (kg/m3) |

β | volume expansion coefficient (1/K) | ||

\(\vec{g}\) | acceleration of gravity (m/s2) | λ | thermal conductivity (W/(m K)) |

h | heat transfer coefficient (W/(m2 K)) | ε | turbulent kinetic energy dissipation rate (m2/s3) |

\(\vec{J}\) | induced current density vector (A/m2) | Φ | generalized dependent variable |

k | turbulent kinetic energy (m2/s2) | ΓΦ | diffusion coefficient associated with Φ |

L | latent heat (kJ/kg) | S Φ | Source term associated with Φ |

P | pressure (Pa) | ||

P K | production term in turbulent kinetic energy equation | ||

Subscripts | |||

Q | joule heat (W/m3) | air | Air |

Q ave | mean joule heat (W/m3) | cast | Cast |

Re | Reynolds number | con | contact |

r e | hydraulic radius of the nozzle (m) | en | environment |

R T | turbulent Reynolds number based on the turbulent quantities | film | Film |

i, j, k | coordinate direction | ||

S T | turbulence intensity | inlet | inlet |

T | temperature (K) | l | liquid |

T P | period of the varying current (s) | oulet | oulet |

t | time (s) | pour | pouring |

U | velocity at wide direction (m/s) | ref | reference |

V | velocity at thickness direction (m/s) | s | solid |

W | velocity at vertical direction (m/s) | ||

Rights and permissions

About this article

Cite this article

Duan, W., Bao, J., Liu, W. et al. 3-D Mathematical Modeling of the Effect of Shunt Plate Hole Distribution and Magnetic Field on Transport Phenomena Within DC Casting of Magnesium Alloy Slab. Metall Mater Trans A 53, 2018–2039 (2022). https://doi.org/10.1007/s11661-022-06645-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06645-x