Abstract

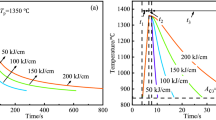

This study is to comprehensively clarify the effect of Nb addition on the particles, austenite grain growth, microstructure evolution, and toughness in the heat-affected zone after high heat input welding at 400 kJ cm−1 for shipbuilding steel plates with Mg deoxidation containing 0.002 and 0.016 wt pct Nb. The Nb addition enhances the dissolution of small particles (< 20 nm) and the coarsening of large particles (> 20 nm) during welding period of T > 1300 °C, because the stability of (Ti, Nb)(C, N) particles is reduced caused by the weaker bonding of Ti–C, Nb–N, and Nb–C. With the temperature above 1300 °C during welding, the austenite grain growth rate increases with Nb addition because the particle pinning force reduces by the small-sized particle dissolution and large-size particle coarsening. Nb addition hinders the ferrite transformation with the transformation temperature decreasing from 700–535 °C to 670–520 °C, due to the increased PAG size. Thus, with Nb addition, the microstructures change from high-temperature fine polygonal ferrite in small prior austenite grains (PAGs) to low-temperature coarse intragranular bainite ferrite in large PAGs, reducing the high-angled grain boundary density from 1.3 to 0.5 μm−1 and increasing the effective grain size from 10.4 to 17.6 μm. Thus, the toughness at − 40 °C decreases from 127 to 58 J.

Similar content being viewed by others

References

J. Yang, L.Y. Xu, K. Zhu, R.Z. Wang, L.J. Zhou, and W.L. Wang: Steel Res. Int., 2015, vol. 86, pp. 619–25.

X.Q. Pan, J. Yang, Q.D. Zhong, Y.L. Qiu, G.G. Cheng, M.Y. Yao, and J.X. Dong: Ironmak. Steelmak., 2020, https://doi.org/10.1080/03019233.2020.1848304.

Y.H. Zhang, J. Yang, D.K. Liu, X.Q. Pan, and L.Y. Xu: Metall. Mater. Trans. A., 2021, vol. 52, pp. 668–79.

X.Q. Pan, J. Yang, and Y.H. Zhang: Steel Res. Int., 2021, https://doi.org/10.1002/srin.202100376.

J. Yang, K. Zhu, R.Z. Wang, and J.G. Shen: Steel Res. Int., 2011, vol. 82, pp. 552–56.

L.Y. Xu, J. Yang, R.Z. Wang, Y.N. Wang, and W.L. Wang: Metall. Mater. Trans. A., 2016, vol. 47, pp. 3354–64.

L.Y. Xu, J. Yang, R.Z. Wang, W.L. Wang, and Y.N. Wang: J. Iron Steel Res. Int., 2018, vol. 25, pp. 433–41.

X.Q. Pan, J.J. Zhi, Z.J. Fan, Y.H. Zhang, and J. Yang: Steel Res. Int., 2021, https://doi.org/10.1002/srin.202100099.

X.Q. Pan, J. Yang, Y.H. Zhang, J. Park, and H. Ono: Mater. Sci. Tech., 2021, vol. 118, p. 409.

L.Y. Xu and J. Yang: Metall. Mater. Trans. A., 2020, vol. 51, pp. 4540–48.

A. Kojima, A. Kiyose, R. Uemori, M. Minagawa, M. Hoshino, T. Nakashima, K. Ishida, and H. Yasui: Nippon Steel Tech. Rep., 2004, vol. 90, pp. 292–413.

G.K. Bansal, V.C. Srivastava, and S.G. Chowdhury: Mater. Sci. Eng. A., 2019, vol. 767, p. 138416.

R.M. Poths, R.L. Higginson, and E.J. Palmiere: Scripta Mater., 2001, vol. 44, pp. 147–51.

T. Gladman: The Physical Metallurgy of Microalloyed Steels, Institute of Materials, London, 1997.

L.M. Fu, H.R. Wang, W. Wang, and A.D. Shan: Mater. Sci. Tech., 2013, vol. 27, pp. 996–1001.

A. Karmakar, S. Kundu, S. Roy, S. Neogy, D. Srivastava, and D. Chakrabarti: Mater. Sci. Tech., 2014, vol. 30, pp. 653–64.

M. Maalekian, R. Radis, M. Militzer, A. Moreau, and W. Poole: Acta Mater., 2012, vol. 60, pp. 1015–26.

X.Q. Pan, J. Yang, Y.H. Zhang, L.Y. Xu, and R.B. Li: Ironmak. Steelmak., 2021, vol. 48, pp. 417–27.

H. Kejian and T.N. Baker: Mater. Sci. Eng. A., 1993, vol. 169, pp. 53–65.

J. Moon, S. Kim, H. Jeong, J. Lee, and C. Lee: Mater. Sci. Eng. A., 2007, vol. 454–455, pp. 648–53.

Y. Chen, D.T. Zhang, Y.C. Liu, H.J. Li, and D.K. Xu: Mater. Charact., 2013, vol. 84, pp. 232–39.

X.Q. Yuan, Z.Y. Liu, S.H. Jiao, L.Q. Ma, and G.D. Wang: ISIJ Int., 2006, vol. 46, pp. 579–85.

G.I. Rees, J. Perdrix, T. Maurickx, and H.K.D.H. Bhadeshia: Mater. Sci. Eng. A., 1995, vol. 194, pp. 179–86.

T. Jia and M. Militzer: Metall. Mater. Trans. A., 2015, vol. 46, pp. 614–21.

X.P. Ma, L.J. Wang, C.M. Liu, and S.V. Subramanian: Mater. Sci. Eng. A., 2011, vol. 528, pp. 6812–18.

K. Hausmann, D. Krizan, K. Spiradek-Hahn, A. Pichler, and E. Werner: Mater. Sci. Eng. A., 2013, vol. 588, pp. 142–50.

X.W. Chen, G.Y. Qiao, X.L. Han, X. Wang, F.R. Xiao, and B. Liao: Mater. Des., 2014, vol. 53, pp. 888–901.

X.L. Wang, Z.Q. Wang, L.L. Dong, C.J. Shang, X.P. Ma, and S.V. Subramanian: Mater. Sci. Eng. A., 2017, vol. 704, pp. 448–58.

A.J. Craven, K. He, L.A.J. Garvie, and T.N. Baker: Acta Mater., 2000, vol. 48, pp. 3857–68.

A.J. Craven, K. He, L.A.J. Garvie, and T.N. Baker: Acta Mater., 2000, vol. 48, pp. 3869–78.

Y. Li and T.N. Baker: Mater. Sci. Tech., 2010, vol. 26, pp. 1029–40.

C.L. Davis and J.E. King: Metall. Mater. Trans. A., 1994, vol. 25, pp. 563–73.

R.A. Farrar, Z. Zhang, S.R. Bannister, and G.S. Barritte: J. Mater. Sci., 1993, vol. 28, pp. 1385–90.

R.C. Sharma, V.K. Lakshmanan, and J.S. Kirkaldy: Metall. Trans. A., 1984, vol. 15, pp. 545–53.

K. Balasubramanian and J.S. Kirkaldy: Calphad., 1986, vol. 10, pp. 187–202.

D.A. Porter and K.E. Easterling: Phase Transformations in Metals and Alloys, Chapman and Hall, London, 1992.

J. Moon, C. Lee, S. Uhm, and J. Lee: Acta Mater., 2006, vol. 54, pp. 1053–61.

I.M. Lifshitz and V.V. Slyozov: J. Phys. Chem. Solids., 1961, vol. 19, pp. 35–50.

W.F. Gale and T.C. Totemeier: Smithells Metals Reference Book, 8th ed., Elsevier Butterworth-Heinemann, Amsterdam, 2004, pp. 6–23, 24.

G. Mao, R. Cao, J. Chen, X. Guo, and Y. Jiang: J. Iron Steel Res. Int., 2017, vol. 24, pp. 1206–14.

H. Zhao, B.P. Wynne, and E.J. Palmiere: J. Mater. Sci., 2018, vol. 53, pp. 3785–3804.

Y. Shen, B. Chen, and C. Wang: Metall. Mater. Trans. A., 2021, vol. 52, pp. 14–19.

Acknowledgments

The authors gratefully acknowledge financial support by the National Natural Science Foundation of China (Grant No. U1960202).

Conflict of interest

The authors declare that they have no conflict of interest

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, X., Yang, J. & Zhang, Y. Microstructure Evolution in Heat-Affected Zone of Shipbuilding Steel Plates with Mg Deoxidation Containing Different Nb Contents. Metall Mater Trans A 53, 1512–1528 (2022). https://doi.org/10.1007/s11661-022-06617-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06617-1