Abstract

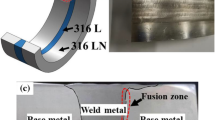

Ethylene pyrolysis furnace tubes are subjected to a variety of failure mechanisms such as creep, oxidation, carburization, and thermal shock. Therefore, proper selection of filler metal and welding process is important in their repair process. In this work, the effect of UTP 2535 Nb and UTP 3545 Nb filler metals on the microstructure, creep behavior, and oxidation resistance of Gas Tungsten Arc WeldedET45 Micro alloy tube is investigated. Based on the results, the microstructure of the joint welded with UTP 2535 Nb filler metal is composed of Chromium and Niobium carbides deposited along the dendritic grain boundaries of the austenitic matrix. The joint welded with UTP 3545Nb filler showed a similar structure, except for denser and more continuous carbides. Compared to the base metal, the weld zone of both samples showed higher hardness values which can be explained by the finer grain size and continuous carbide networks. Also, the higher Chromium content of UTP 3545 Nb filler metal resulted in higher carbide content and higher hardness than the joint welded with UTP 2535 Nb. Tension test results showed that in both specimens, fracture occurred in the base metal. Both samples delivered the same properties in terms of elongation, yield strength, and tensile strength, which were dictated by the mechanical properties of the base metal. In all temperatures, the joint welded with UTP 2535 Nb filler metal exhibited higher rupture time and creep resistance than the specimen welded with UTP 3545 Nb filler metal. It can be attributed to the continuous inter-dendritic carbides in the weld zone of the latter sample; cracks are prone to propagate along the carbides/dendrites interface during the creep test. Based on the oxidation test results, the joint welded with UTP 3545 Nb filler metal showed lower mass gain (3.6 mg cm−2) and oxide thickness (11 µm) compared to the joint welded with UTP 2535 Nb filler (4.3 mg cm−2 and 20 µm, respectively).

Graphical abstract

Similar content being viewed by others

References

Z. Zhao, K. Chong, J. Jiang, K. Wilson, X. Zhang, and F. Wang: Renew. Sustain. Energy Rev., 2018, vol. 97, pp. 580–91.

A. Chauhan, M. Anwar, K. Montero, H. White, and W. Si: J. Phase Equilib. Diffus., 2006, vol. 27, pp. 684–90.

ΗΜ Τawancy: Eng. Fail. Anal., 2009, vol. 16, pp. 2171–78.

B. Hu, X. Chen, C. Liu, X. Lian, and T. Chen: Mater. High Temp., 2019, vol. 36, pp. 489–98.

A. Sharma, S. Kumar, Z. Duriagina: Engineering Steels and High Entropy-Alloys. BoD–Books on Demand, 2020.

S. Borjali, S.R. Allahkaram, and H. Khosravi: Mater. Des., 2012, vol. 34, pp. 65–73.

J. Guo, T. Cao, C. Cheng, X. Meng, and J. Zhao: Eng. Fail. Anal., 2020, 104610.

M.N. Ilman: Eng. Fail. Anal., 2014, vol. 42, pp. 100–08.

S.H. Khodamorad, D.H. Fatmehsari, H. Rezaie, and A. Sadeghipour: Eng. Fail. Anal., 2012, vol. 21, pp. 1–8.

K. Shiga, Y. Hara, E. Yamamoto: in: ASME Pressure Vessels and Piping Conference, 2008, vol. 48302, pp. 433–38.

K.D. Ramkumar, N. Arivazhagan, and S. Narayanan: Mater. Des., 2012, vol. 40, pp. 70–79.

A. Reihani, S.A. Razavi, E. Abbasi, and A.R. Etemadi: J. Fail. Anal. Prev., 2013, vol. 13, pp. 658–65.

J. Guo, C. Cheng, H. Li, J. Zhao, and X. Min: Eng. Fail. Anal., 2017, vol. 79, pp. 625–33.

C. Liu, X. Chen, T. Chen, D. Nie, and L. Wang: Mater. High Temp., 2016, vol. 33, pp. 98–104.

J. Sun, W. Ren, P. Nie, J. Huang, K. Zhang, and Z. Li: Mater. Design., 2019, vol. 175, p. 107823.

J. Guo, W. Liu, C. Li, and X. Zhang: Metall. Res. Technol., 2020, vol. 117, pp. 612–20.

J. Guo, T. Cao, C. Cheng, X. Meng, and J. Zhao: Sci. Technol. Weld. Join., 2018, vol. 23, pp. 449–53.

A. Reihani and R.D. Haghighi: Eng. Fail. Anal., 2015, vol. 52, pp. 97–108.

S.R. Allahkaram, S. Borjali, and H. Khosravi: Mater. Des., 2012, vol. 33, pp. 476–84.

S.L. Jeng and Y.H. Chang: Mater. Sci. Eng. A., 2012, vol. 555, pp. 1–2.

N. Taheri, H. Naffakh-Moosavy, and F.M. Ghaini: Opt. Laser Technol., 2017, vol. 91, pp. 71–79.

K. Nomura, K. Kubushiro, H. Nakagawa, and Y. Murata: Mater. Trans., 2016, vol. 57, pp. 2097–2103.

A.K. Lakshminarayanan, K. Shanmugam, and V. Balasubramanian: J. Iron. Steel Res. Int., 2009, vol. 16, pp. 62–68.

Y.C. Lin, L. Li, D.G. He, M.S. Chen, and G.Q. Liu: Mater. Sci. Eng. A., 2017, vol. 679, pp. 401–09.

Z. Li, Z. Wen, S. Gu, H. Pei, H. Gao, and Q. Mao: J. Alloy. Compd., 2019, vol. 793, pp. 65–76.

L. Cao, G. Xie, Z. Han, F. Zhuang: Effect of Carburization on Creep Performance of Cr35Ni45Nb Heat Resistant Alloy, Vessels and Piping Conference American Society of Mechanical Engineers, 2018, pp. 51678.

L. Cui, H. Su, J. Yu, J. Liu, T. Jin, and X. Sun: Mater. Sci. Eng. A., 2017, vol. 707, pp. 383–91.

W.Z. Wang, F.Z. Xuan, Z.D. Wang, B. Wang, and C.J. Liu: Mater. Des., 2011, vol. 32, pp. 4010–16.

A.R. Andrade, C. Bolfarini, L.A. Ferreira, C.D. Souza Filho, and L.H. Bonazzi: Mater. Sci. Eng. A., 2015, vol. 636, pp. 48–52.

Y. Li, X. Fan, H. Cui, F. Lu, and X. Tang: The correlated mechanism of creep fracture and microstructure evolution for precipitated Nimonic 263 superalloy welding joint. Sci. Technol. Weld. Join., 2020, vol. 26, pp. 37–46.

T. Dudziak, K. Jura, A. Polkowska, V. Deodeshmukh, M. Warmuzek, M. Witkowska, W. Ratuszek, and K. Chruściel: Oxid. Met., 2018, vol. 89, pp. 755–79.

R. Song and S. Wu: Eng. Fail. Anal., 2018, vol. 88, pp. 63–72.

P. Berthod and E. Conrath: Mater. Des., 2016, vol. 104, pp. 27–36.

M.A. Razmjoo-Khollari, M.K. Azar, M. Esmaeili, N. Malekpour, S.M. Hosseini-Hosseinabad, R.S. Moakhar, A. Dolati, and S. Ramakrishna: ACS Appl. Energy Mater., 2021, vol. 4, p. 5304.

A. Bakhshi-Zadeh, S. Salmani, M.A. Faghihi-Sani, H. Abdoli, and N. Jalili: Oxid. Met., 2020, vol. 93, pp. 1–5.

A.A. Kaya, P. Krauklis, and D.J. Young: Mater. Charact., 2002, vol. 49, pp. 11–21.

E. Bahmani, A. Zakeri, and A.S. Aghdam: Surf. Interfaces., 2021, vol. 26, p. 101288.

S. Guo, D. Xu, N. Wei, Y. Wang, G. Chen, and S. Wang: Ind. Eng. Chem. Res., 2020, vol. 59, pp. 10278–88.

Y. Nishiyama, N. Otsuka, and T. Nishizawa: Corrosion., 2003, vol. 59, pp. 688–700.

Acknowledgments

The authors thank the support from Islamic Azad University for providing the funding for this research.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 22, 2021; accepted January 5, 2022.

Rights and permissions

About this article

Cite this article

Ahmadizadeh, E., Derakhshandeh-Haghighi, R., Rabiezadeh, A. et al. Creep and Oxidation Behavior of GTAW Welded ET45 Micro Alloy Tube. Metall Mater Trans A 53, 1361–1378 (2022). https://doi.org/10.1007/s11661-022-06595-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06595-4