Abstract

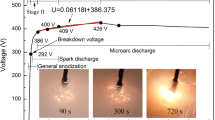

The growth kinetics mechanism of microarc oxidation (MAO) coatings on Ti6Al4V alloy in a magnetic field with a low current density of 2 A/dm2 was studied using scanning electron microscopy, energy dispersive spectroscopy, atomic force microscope, X-ray diffraction, and potentiodynamic polarization. The results show that the magnetohydrodynamics effect increased the electron current density during the MAO process. Then, a higher breakdown voltage of the anodic oxide film, faster growth of the MAO coatings, stronger and more concentrated microarc are obtained. Consequently, thick uneven coatings with high content of co-deposition oxides were obtained on samples rotating at 500 r/min in the magnetic field, resulting in uneven dense layer and poor corrosion resistance of the coating; the thin uniform coatings with a few co-deposition oxides were obtained on samples rotating at 3500 r/min in the magnetic field and also have poor corrosion resistance; both thickness and uniformity of the coatings are improved only for the sample rotating at 1500 r/min, resulting in good corrosion resistance of the coating. The thickness of the MAO coatings obtained on the low-speed rotating samples in the magnetic field increased parabolically with time, whereas that on high-speed rotating samples tends to increase linearly with time.

Similar content being viewed by others

References

B. Ellyson, J. Klemm-Toole, K. Clarke, R. Field, and M. Kaufman: Scripta. Mater., 2021, vol. 194, p. 113641.

S. Liao, C. Chang, C. Chen, C.H. Lee, and W.L. Lin: Surf. Coat. Tech., 2020, vol. 394, p. 125812.

L. Choisez, L. Ding, M. Marteleur, H. Idrissi, T. Pardoen, and P.J. Jacques: Nat. Commun., 2020, vol. 11, p. 2110.

F. Cheng, S. Li, W. Gui, and J. Lin: Prog. Nat. Sci., 2018, vol. 28, pp. 386–90.

Y. Mao, J. Yan, L. Wang, W. Dong, Y. Jia, X. Hu, and X. Wang: Ceram. Int., 2018, vol. 44, pp. 12978–86.

A. Jangde, S. Kumar, and C. Blawert: Corros. Sci., 2019, vol. 157, pp. 220–46.

A. Fattah-alhosseini, M. Molaei, N. Attarzadeh, K. Babaei, and F. Attarzadeh: Ceram. Int., 2020, vol. 46, pp. 20587–607.

B. Mingo, Y. Guo, A. Němcová, A. Gholinia, M. Mohedano, M. Sun, A. Matthews, and A. Yerokhin: Electrochim. Acta., 2019, vol. 299, pp. 772–88.

M. Kaseem and H.C. Choe: Corros. Sci., 2021, vol. 192, p. 109764.

M.J. Hwang, H.R. Choi, H.J. Song, and Y.J. Park: J. Alloys Compd., 2018, vol. 732, pp. 95–106.

C. Demirbas, A. Ayday: Surf. Eng. 2021, vol. 37, pp. 24–31.

Y.J. Chu, P. Liu, Y.X. Chen, and X.Q. Li: Mater. Res-Ibero-Am. J., 2020, vol. 23, p. e20200002.

A. K. Vijh: Corros. Sci., 1971, vol. 11, pp. 0–167.

J. Yahalom: J. Electrochem. Inc., 1973, vol. 10, pp. 503–6.

S. Ikonopisov, A. Girginov, and M. Machkova: Electrochim. Acta., 1977, vol. 22, pp. 1283–6.

J.M. Albella, I. Montero, and J.M. Martinez-Duart: Electrochim. Acta., 1987, vol. 32, pp. 255–8.

G. Mortazavi, J.C. Jiang, and E.I. Meletis: Appl. Surf. Sci., 2019, vol. 488, pp. 370–82.

K. Venkateswarlu, N. Rameshbabu, D. Sreekanth, M. Sandhyarani, A.C. Bose, and V. Muthupandi: Electrochim. Acta., 2015, vol. 105, pp. 468–80.

D. Zhai, K. Feng, and H. Yue: Metall. Mater. Trans. A., 2019, vol. 50, pp. 2507–18.

M. Stern and A.L. Geary: J. Electrochem. Soc., 1957, vol. 104, pp. 56–63.

J. Jang and S.S. Lee: Actuat. A., 2000, vol. 80, pp. 84–9.

S.W. Guan, M. Qi, Y.D. Li, and W.Q. Wang: Surf. Coat. Tech., 2020, vol. 395, p. 125948.

T.W. Clyne and S.C. Troughton: Int. Mater. Rev., 2018, vol. 64, pp. 1–36.

A. Nominé, S.C. Troughton, A.V. Nominé, G. Henrion, and T.W. Clyne: Surf. Coat. Tech., 2015, vol. 269, pp. 125–30.

R.G. Ehl and A.J. Ihde: J. Chem. Educ., 1954, vol. 31, p. 226.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 21, 2021; accepted November 20, 2021.

Rights and permissions

About this article

Cite this article

Zhai, D., Li, X., Shen, J. et al. Mechanism of Microarc Oxidation Treated Ti6Al4V Alloy in a Magnetic Field. Metall Mater Trans A 53, 1200–1207 (2022). https://doi.org/10.1007/s11661-021-06555-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06555-4