Abstract

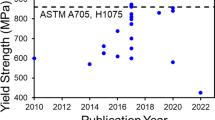

This paper demonstrates how an analytical and experimental method can be used to rapidly define the additive manufacturing settings for a new alloy where the process parameters were previously unknown. A nickel-based superalloy, Haynes 282, was chosen for the analysis. An experimental matrix of focused processing parameters was predicted with a dimensionless number and 100 samples were printed using the Laser Powder Bed Fusion technique. High-throughput measurements validated the predicted process conditions needed to achieve desired density and hardness. The whole process was completed in 16 hours. The new technique was confirmed with analytical processing maps adopted by the metal additive manufacturing community. With the predicted set of process parameters, a low-throughput analyses of conventional microstructural characterizations and tensile testing were used to test the predictions. The resultant as-fabricated microstructures have refined length scales of both microsegregation and secondary phase distributions. The mechanical properties were comparable within the predicted processing window and exhibited high strength and high ductility.

Similar content being viewed by others

References

D. Zhang, S. Sun, D. Qiu, M.A. Gibson, M.S. Dargusch, M. Brandt, M. Qian, and M. Easton: Adv. Eng. Mater., 2018, vol. 20(5), p. 1700952.

W.E. Frazier: J. Mater. Eng. Perform., 2014, vol. 23(6), pp. 1917–28.

T.M. Pollock, A.J. Clarke, and S.S. Babu: Metall. Mater. Trans. A., 2020, vol. 51A(12), pp. 6000–19.

S.S. Babu, N. Raghavan, J. Raplee, S.J. Foster, C. Frederick, M. Haines, R. Dinwiddie, M.K. Kirka, A. Plotkowski, Y. Lee, and R.R. Dehoff: Metall. Mater. Trans. A., 2018, vol. 49A(9), pp. 3764–80.

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang: Prog. Mater Sci., 2018, vol. 92, pp. 112–224.

D. Herzog, V. Seyda, E. Wycisk, and C. Emmelmann: Acta Mater., 2016, vol. 117, pp. 371–92.

D. Bourell, J.P. Kruth, M. Leu, G. Levy, D. Rosen, A.M. Beese, and A. Clare: CIRP Ann., 2017, vol. 66(2), pp. 659–81.

L. Thijs, M.L. Montero Sistiaga, R. Wauthle, Q. Xie, J.-P. Kruth, and J. Van Humbeeck: Acta Mater., 2013, vol. 61(12), pp. 4657–68.

P. Mercelis and J.P. Kruth: Rapid Prototyp. J., 2006, vol. 12(5), pp. 254–65.

K.M. Bertsch, G. Meric de Bellefon, B. Kuehl, and D.J. Thoma: Acta Mater., 2020, vol. 199, pp. 19–33.

K. Tomasz, C. Edward, K. Bogumiła, and R. Jacek: in Proc.SPIE, 2012.

J.L. Tan, C. Tang, and C.H. Wong: Metall. Mater. Trans. A., 2018, vol. 49A(8), pp. 3663–73.

S.-K. Rittinghaus and J. Zielinski: Metall. Mater. Trans. A., 2021, vol. 52A(3), pp. 1106–16.

A. Caggiano, J. Zhang, V. Alfieri, F. Caiazzo, R. Gao, and R. Teti: CIRP Ann., 2019, vol. 68(1), pp. 451–4.

A.K. Agrawal, G. Meric de Bellefon, and D. Thoma: Mater. Sci. Eng. A., 2020, vol. 793, p. 139841.

Yadroitsev, I.: LAP LAMBERT Academic Publishing.

A.I. Saville, S.C. Vogel, A. Creuziger, J.T. Benzing, A.L. Pilchak, P. Nandwana, J. Klemm-Toole, K.D. Clarke, S.L. Semiatin, and A.J. Clarke: Addit. Manuf., 2021, vol. 46, p. 102118.

S.-H. Sun, K. Hagihara, and T. Nakano: Mater. Des., 2018, vol. 140, pp. 307–16.

F. Geiger, K. Kunze, and T. Etter: Mater. Sci. Eng. A., 2016, vol. 661, pp. 240–6.

C.Y. Liu, J.D. Tong, M.G. Jiang, Z.W. Chen, G. Xu, H.B. Liao, P. Wang, X.Y. Wang, M. Xu, and C.S. Lao: Mater. Sci. Eng. A., 2019, vol. 766, p. 138364.

A. Kudzal, B. McWilliams, C. Hofmeister, F. Kellogg, J. Yu, J. Taggart-Scarff, and J. Liang: Mater. Des., 2017, vol. 133, pp. 205–15.

X. Zhao, S. Dong, S. Yan, X. Liu, Y. Liu, D. Xia, Y. Lv, P. He, B. Xu, and H. Han: Mater. Sci. Eng. A., 2020, vol. 771, p. 138557.

B. Rankouhi, D.J. Thoma, and K. Suresh, Manufacturing in the Era of 4th Industrial Revolution, World Scientific, 2020, pp. 9–40.

L. Cheng, X. Liang, J. Bai, Q. Chen, J. Lemon, and A. To: Addit. Manuf., 2019, vol. 27, pp. 290–304.

A. Bandyopadhyay and K.D. Traxel: Addit. Manuf., 2018, vol. 22, pp. 758–74.

K.H. Leitz, P. Singer, A. Plankensteiner, B. Tabernig, H. Kestler, and L.S. Sigl: Met. Powder Rep., 2017, vol. 72(5), pp. 331–8.

B. Rankouhi, A.K. Agrawal, F.E. Pfefferkorn, and D.J. Thoma: Manuf. Lett., 2021, vol. 27, pp. 13–7.

N.K. Terrett, M. Gardner, D.W. Gordon, R.J. Kobylecki, and J. Steele: Tetrahedron., 1995, vol. 51(30), pp. 8135–73.

P.P. Pescarmona, J.C. van der Waal, I.E. Maxwell, and T. Maschmeyer: Catal. Lett., 1999, vol. 63(1), pp. 1–11.

L.A. Thompson and J.A. Ellman: Chem. Rev., 1996, vol. 96(1), pp. 555–600.

Y. Zhao, N. Sargent, K. Li, and W. Xiong: Materialia., 2020, vol. 13, p. 100835.

J.W. Pegues, M.A. Melia, R. Puckett, S.R. Whetten, N. Argibay, and A.B. Kustas: Addit. Manuf., 2021, vol. 37, p. 101598.

K. Huang, C. Kain, N. Diaz-Vallejo, Y. Sohn, and L. Zhou: J. Manuf. Process., 2021, vol. 66, pp. 494–505.

D. Kong, C. Dong, X. Ni, L. Zhang, C. Man, J. Yao, Y. Ji, Y. Ying, K. Xiao, X. Cheng, and X. Li: J. Alloys Compd., 2019, vol. 785, pp. 826–37.

M.A. Melia, S.R. Whetten, R. Puckett, M. Jones, M.J. Heiden, N. Argibay, and A.B. Kustas: Appl. Mater. Today., 2020, vol. 19, p. 100560.

M.L. Green, I. Takeuchi, and J.R. Hattrick-Simpers: J. Appl. Phys., 2013, vol. 113(23), p. 231101.

S. Liu, A.P. Stebner, B.B. Kappes, and X. Zhang: Addit. Manuf., 2021, vol. 39, p. 101877.

D.B. Miracle, M. Li, Z. Zhang, R. Mishra, and K.M. Flores: Annu. Rev. Mater. Res., 2021, vol. 51(1), pp. 131–64.

K.L. Kruger: Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants, A. Di Gianfrancesco, ed., Woodhead Publishing, 2017, pp. 511–545.

L.M. Pike: ASME Turbo Expo 2006: Power for Land, Sea, and Air, 2006.

M.C. Hardy, M. Detrois, E.T. McDevitt, C. Argyrakis, V. Saraf, P.D. Jablonski, J.A. Hawk, R.C. Buckingham, H.S. Kitaguchi, and S. Tin: Metall. Mater. Trans. A., 2020, vol. 51A(6), pp. 2626–50.

K. Moussaoui, W. Rubio, M. Mousseigne, T. Sultan, and F. Rezai: Mater. Sci. Eng. A., 2018, vol. 735, pp. 182–90.

A. Deshpande, S. Deb Nath, S. Atre, and K. Hsu: Metals., 2020, vol. 10(5), p. 629.

M. Balbaa, S. Mekhiel, M. Elbestawi, and J. McIsaac: Mater. Des., 2020, vol. 193, p. 108818.

R. Otto, V. Brøtan, A.S. Azar, and O. Åsebø: TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings, Springer International Publishing, Cham, 2019.

J. Boswell, J. Jones, N. Barnard, D. Clark, M. Whittaker, and R. Lancaster: Mater. Des., 2021, vol. 205, p. 109725.

E. Liverani, S. Toschi, L. Ceschini, and A. Fortunato: J. Mater. Process. Technol., 2017, vol. 249, pp. 255–63.

C.A. Schneider, W.S. Rasband, and K.W. Eliceiri: Nat. Methods., 2012, vol. 9(7), pp. 671–5.

B. Kappes, S. Moorthy, D. Drake, H. Geerlings, and A. Stebner, Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications, Springer International Publishing, Cham, 2018.

S.W. Hughes: Phys. Educ., 2005, vol. 40(5), pp. 468–74.

International, A., ASTM, 2013.

M. Tang, P.C. Pistorius, and J.L. Beuth: Addit. Manuf., 2017, vol. 14, pp. 39–48.

W.E. King, H.D. Barth, V.M. Castillo, G.F. Gallegos, J.W. Gibbs, D.E. Hahn, C. Kamath, and A.M. Rubenchik: J. Mater. Process. Technol., 2014, vol. 214(12), pp. 2915–25.

J. Risse and C. Broeckmann: Lehrstuhl für Lasertechnik, 2019.

J. Zhang, D. Gu, Y. Yang, H. Zhang, H. Chen, D. Dai, and K. Lin: Engineering., 2019, vol. 5(4), pp. 736–45.

C.D. Boley, S.A. Khairallah, and A.M. Rubenchik: Appl. Opt., 2015, vol. 54(9), pp. 2477–82.

U. Scipioni Bertoli, A.J. Wolfer, M.J. Matthews, J.-P.R. Delplanque, and J.M. Schoenung: Mater. Des., 2017, vol. 113, pp. 331–40.

X. Wang, L.N. Carter, B. Pang, M.M. Attallah, and M.H. Loretto: Acta Mater., 2017, vol. 128, pp. 87–95.

P. Promoppatum, S.-C. Yao, P.C. Pistorius, and A.D. Rollett: Engineering., 2017, vol. 3(5), pp. 685–94.

J. Xu, H. Gruber, R. Boyd, S. Jiang, R.L. Peng, and J.J. Moverare: Materialia., 2020, vol. 10, p. 100657.

K. Amato, J. Hernandez, L. Murr, E. Martinez, S. Gaytan, P. Shindo, and S. Collins: J. Mater. Sci. Res., 2012, vol. 1(2), p. 3.

L.O. Osoba, R.G. Ding, and O.A. Ojo: Mater. Charact., 2012, vol. 65, pp. 93–9.

G.E. Bean, T.D. McLouth, D.B. Witkin, S.D. Sitzman, P.M. Adams, and R.J. Zaldivar: J. Mater. Eng. Perform., 2019, vol. 28(4), pp. 1942–9.

Y.T. Tang, C. Panwisawas, J.N. Ghoussoub, Y. Gong, J.W.G. Clark, A.A.N. Németh, D.G. McCartney, and R.C. Reed: Acta Mater., 2021, vol. 202, pp. 417–36.

B. Zhang, P. Wang, Y. Chew, Y. Wen, M. Zhang, P. Wang, G. Bi, and J. Wei: Mater. Sci. Eng. A., 2020, vol. 794, p. 139941.

Acknowledgments

Support from DOE/EERE Advanced Manufacturing Office under award DE-EE0009138 is gratefully acknowledged. Support from the University of Wisconsin-Madison UW2020 program for the EOS M290 is also acknowledged. The electron microscopy was carried out using facilities and instrumentation that are partially supported by the NSF through the Materials Research Science and Engineering Center (DMR-1720415).

Author Contributions

ZI: Methodology, Data curation, Writing—original draft. AKA: Methodology, Writing—review and editing. BR: Methodology, Writing—review and editing. CM: mechanical testing. MHA: Supervision, Mechanical testing. FEP: Supervision, Methodology, Writing—review and editing. DJT: Conceptualization, Methodology, Supervision, Resources, Funding acquisition, Project administration, Writing—original draft, review and editing.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted June 27, 2021; accepted October 25, 2021.

Rights and permissions

About this article

Cite this article

Islam, Z., Agrawal, A.K., Rankouhi, B. et al. A High-Throughput Method to Define Additive Manufacturing Process Parameters: Application to Haynes 282. Metall Mater Trans A 53, 250–263 (2022). https://doi.org/10.1007/s11661-021-06517-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06517-w