Abstract

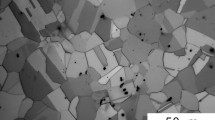

Hydrogen embrittlement can occur in steels with metastable phases, due to activation of the hydrogen-enhanced decohesion mechanism upon transformation. Meanwhile, recent investigations suggest that alloys undergoing ε-martensite transformation may exhibit resistance to hydrogen embrittlement. To better understand hydrogen effects in these alloys, we investigate the hydrogen-induced microstructural transformations in a metastable Fe45Mn35Co10Cr10 alloy. To this end, we electrochemically charge unstrained samples, quantify the hydrogen evolution by thermal desorption spectroscopy, and observe microstructural transformations by scanning electron microscopy techniques. Through these analyses, we find that the hydrogen-induced ε-martensite formation is dependent on the crystallographic orientation of the austenite grains, and takes place preferentially along Σ3 boundaries. Further charging of hydrogen induces extension twinning within the martensite. We examine the microstructural factors influencing these transformations to better understand the hydrogen-microstructure interactions.

Graphical Abstract

reproduced from Ref. [43] with permission of the author (Figure 1(c) is reproduced with permission from Plastic strain-induced sequential martensitic transformation by S.L. Wei et. al. published in Scripta Materialia, vol.185 (2020), Ref. [43].). (d) Experimental TDS curve for a sample H charged for 106 hours, along with deconvoluted peaks (dashed lines) corresponding H release at increasing energies: (1) diffusible hydrogen, (2) thermal ε-γ transformation, (3) Σ3 twin boundaries

Similar content being viewed by others

References

S.K. Dwivedi and M. Vishwakarma: Int. J. Hydrogen Energy., 2019, vol. 44, pp. 28007–30.

S. Lynch: Corros. Rev., 2012, vol. 30, pp. 105–23.

M. Nagumo: Fundamentals of Hydrogen Embrittlement, Springer Singapore, Singapore, 2016.

R.M. McMEEKING and A.G. EVANS: J. Am. Ceram. Soc. https://doi.org/10.1111/j.1151-2916.1982.tb10426.x.

S.K. Hann and J.D. Gates: J. Mater. Sci. https://doi.org/10.1023/A:1018544204267.

S.D. Antolovich and B. Singh: Metall. Mater. Trans. B., 1971, vol. 2, pp. 2135–41.

J.H. Ryu, Y.S. Chun, C.S. Lee, H.K.D.H. Bhadeshia, and D.W. Suh: Acta Mater., 2012, vol. 60, pp. 4085–92.

S.D. Pu, A. Turk, S. Lenka, and S.W. Ooi: Mater. Sci. Eng. A., 2019, vol. 754, pp. 628–35.

M. Koyama, D. Yamasaki, T. Nagashima, C.C. Tasan, and K. Tsuzaki: Scr. Mater., 2017, vol. 129, pp. 48–51.

A. Laureys, T. Depover, R. Petrov, and K. Verbeken: in International Journal of Hydrogen Energy, 2015.

Y.D. Park, I.S. Maroef, A. Landau, and D.L. Olson: Weld. Res., 2002, pp. 27–35.

K.G. Solheim, J.K. Solberg, J. Walmsley, F. Rosenqvist, and T.H. Bjørnå: Eng. Fail. Anal., 2013, vol. 34, pp. 140–9.

B.C. Cameron, M. Koyama, and C.C. Tasan: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2019, vol. 50, pp. 29–34.

A. Inoue, Y. Hosoya, and T. Masumoto: Trans Iron Steel Inst Jpn., 1979, vol. 19, pp. 170–8.

M. Koyama, C.C. Tasan, and K. Tsuzaki: Eng. Fract. Mech., 2019, vol. 214, pp. 123–33.

M. Koyama, C.C. Tasan, T. Nagashima, E. Akiyama, D. Raabe, and K. Tsuzaki: Philos. Mag. Lett., 2016, vol. 96, pp. 9–18.

M. Koyama, T. Eguchi, K. Ichii, C.C. Tasan, and K. Tsuzaki: Procedia Struct. Integr., 2018, vol. 13, pp. 292–7.

G.S. Mogilny, S.M. Teus, V.N. Shyvanyuk, and V.G. Gavriljuk: Mater. Sci. Eng. A., 2015, vol. 648, pp. 260–4.

C. Pan, W.Y. Chu, Z.B. Li, D.T. Liang, Y.J. Su, K.W. Gao, and L.J. Qiao: Mater. Sci. Eng. A., 2003, vol. 351, pp. 293–8.

Q. Yang, L.J. Qiao, S. Chiovelli, and J.L. Luo: Scr. Mater., 1999, vol. 40, pp. 1209–14.

N. Narita, C.J. Altstetter, and H.K. Birnbaum: Metall. Trans. A Phys. Metall. Mater. Sci., 1982, vol. 13 A, pp. 1355–65.

S. Tähtinen, P. Nenonen, and H. Hänninen: Chemistry and Physics of Fracture, Springer, Netherlands, 1987, pp. 568–73.

M.L. Holzworth and M.R. Louthan: Corrosion., 1968, vol. 24, pp. 110–24.

A. Röhsler, O. Sobol, G. Nolze, W.E.S. Unger, and T. Böllinghaus: J. Vac. Sci. Technol. B, Nanotechnol. Microelectron. Mater. Process. Meas. Phenom., 2018, vol. 36, p. 03F103.

A. Głowacka, M.J. Woźniak, G. Nolze, and W.A. Świątnicki: in Solid State Phenomena, vol. 112, 2006, pp. 133–40.

J.M. Rigsbee: Metallography., 1978, vol. 11, pp. 493–8.

S.M. Teus, V.N. Shyvanyuk, and V.G. Gavriljuk: Mater. Sci. Eng. A., 2008, vol. 497, pp. 290–4.

S. Tähtinen, P. Nenonen, and H. Hänninen: Scr. Metall., 1986, vol. 20, pp. 153–7.

V.N. Shivanyuk, J. Foct, and V.G. Gavriljuk: Scr. Mater., 2003, vol. 49, pp. 601–6.

S. Pu: MPhil Thesis, University of Cambridge, 2018.

M. Koyama, N. Terao, and K. Tsuzaki: Mater. Lett., 2019, vol. 249, pp. 197–200.

J.A. Venables: Philos. Mag., 1962, vol. 7, pp. 35–44.

Q. Yang and J.L. Luo: Mater. Sci. Eng. A., 2000, vol. 288, pp. 75–83.

L. Claeys, T. Depover, I. DeGraeve, and K. Verbeken: Corrosion, 2018, p. 2959.

M. Tanino, H. Komatsu, and S. Funaki: in Journal de Physique (Paris), Colloque, vol. 43, EDP Sciences, 1982, pp. C4-503-C4-508.

A. Röhsler, O. Sobol, W.E.S. Unger, and T. Böllinghaus: Int. J. Hydrogen Energy., 2019, vol. 44, pp. 12228–38.

R.P. Frohmberg, W.J. Barnett, and A.R. Troiano: ASM Trans., 1955, vol. 47, pp. 892–925.

M.B. WHITEMAN and A.R. Troiano: Phys. Status solidi.

A.E. Pontini and J.D. Hermida: Scr. Mater., 1997, vol. 37, pp. 1831–7.

P.J. Ferreira, I.M. Robertson, and H.K. Birnbaum: Mater. Sci. Forum., 1996, vol. 207–209, pp. 93–6.

J.D. Hermida and A. Roviglione: Scr. Mater., 1998, vol. 39, pp. 1145–9.

M. Koyama, K. Hirata, Y. Abe, A. Mitsuda, S. Iikubo, and K. Tsuzaki: Sci. Rep., 2018, vol. 8, pp. 1–8.

S. Wei, J. Kim, J.L. Cann, R. Gholizadeh, N. Tsuji, and C.C. Tasan: Scr. Mater., 2020, vol. 185, pp. 36–41.

S. Wei, M. Jiang, and C.C. Tasan: Metall. Mater. Trans. A., 2019, vol. 50, pp. 3985–91.

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan: Nature., 2016, vol. 534, pp. 227–30.

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka, and D. Raabe: Acta Mater., 2015, vol. 94, pp. 124–33.

H. Yan, J. Kim, and C.C. Tasan: Acta Mater. 2021, submitted.

M. Koyama, A. Bashir, M. Rohwerder, S.V. Merzlikin, E. Akiyama, K. Tsuzaki, and D. Raabe: J. Electrochem. Soc., 2015, vol. 162, pp. C638–47.

M. Koyama and K. Tsuzaki: ISIJ Int., 2015, vol. 55, pp. 2269–71.

S. Takagi, K. Kamijo, T. Usuda, H. Kawachi, and K. Hanaki: 18th IMEKO World Congr. 2006 Metrol. a Sustain. Dev., 2006, vol. 1, pp. 813–7.

Z. Hua, B. An, T. Iijima, C. Gu, and J. Zheng: Scr. Mater., 2017, vol. 131, pp. 47–50.

J. Li, A. Oudriss, A. Metsue, J. Bouhattate, and X. Feaugas: Sci. Rep., 2017, vol. 7, pp. 1–9.

J. Song and W.A. Curtin: Acta Mater., 2014, vol. 68, pp. 61–9.

R. Oriani: Acta Metall., 1970, vol. 18, pp. 147–57.

S. Kajiwara: Metall. Mater. Trans. A., 1986, vol. 17, pp. 1693–702.

Y.A. Du, L. Ismer, J. Rogal, T. Hickel, J. Neugebauer, and R. Drautz: Phys. Rev. B, 2011, vol. 84, pp. 1–13.

A. Tehranchi and W.A. Curtin: J. Mech. Phys. Solids., 2017, vol. 101, pp. 150–65.

G.B. Olson and M. Cohen: Metall. Trans. A., 1976, vol. 7, pp. 1905–14.

J.B. Cohen and J. Weertman: Acta Metall., 1963, vol. 11, pp. 996–8.

Y.F. Guo, S. Xu, X.Z. Tang, Y.S. Wang, and S. Yip: J. Appl. Phys. https://doi.org/10.1063/1.4881756.

J.T. Czernuszka, N.J. Long, E.D. Boyes, and P.B. Hirsch: Philos. Mag. Lett. https://doi.org/10.1080/09500839008215127.

D. Ilin: Université de Bordeaux, 2014.

K. Hirata, S. Iikubo, M. Koyama, K. Tsuzaki, and H. Ohtani: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2018, vol. 49, pp. 5015–22.

A.F. Bower: Applied Mechanics of Solids , Taylor & Francis, 2012.

M. Koyama, S.M. Taheri-Mousavi, H. Yan, J. Kim, B.C. Cameron, S.S. Moeini-Ardakani, J. Li, and C.C. Tasan: Sci. Adv., 2020, vol. 6, p. eaaz1187.

W. Pantleon: Scr. Mater., 2008, vol. 58, pp. 994–7.

Y. Matsuoka, T. Iwasaki, N. Nakada, T. Tsuchiyama, and S. Takaki: ISIJ Int., 2013, vol. 53, pp. 1224–30.

Z. Xie, Y. Wang, C. Lu, and L. Dai: Mater. Today Commun., 2021, vol. 26, p. 101902.

G.B. Olson and M. Cohen: Metall. Trans. A., 1976, vol. 7, pp. 1897–904.

I.M. Robertson: Eng. Fract. Mech., 1999, vol. 64, pp. 649–73.

G. Xu, C. Wang, J.I. Beltrán, J. Llorca, and Y. Cui: Comput. Mater. Sci., 2016, vol. 118, pp. 103–11.

S. Dash and N. Brown: Acta Metall., 1966, vol. 14, pp. 595–603.

M. Koyama, E. Akiyama, Y.K. Lee, D. Raabe, and K. Tsuzaki: Int. J. Hydrogen Energy., 2017, vol. 42, pp. 12706–23.

M. Ueda, H.Y. Yasuda, and Y. Umakoshi: Acta Mater., 2003, vol. 51, pp. 1007–17.

T. Song and B.C. De Cooman: ISIJ Int., 2014, vol. 54, pp. 2394–403.

X. Zhu, W. Li, H. Zhao, L. Wang, and X. Jin: https://doi.org/10.1016/j.ijhydene.2014.06.079.

J. Takahashi, K. Kawakami, Y. Kobayashi, and T. Tarui: Scr. Mater., 2010, vol. 63, pp. 261–4.

Y.S. Chen, P.A.J. Bagot, M.P. Moody, and D. Haley: Int. J. Hydrogen Energy., 2019, vol. 44, pp. 32280–91.

J. Takahashi, K. Kawakami, and T. Tarui: Scr. Mater., 2012, vol. 67, pp. 213–6.

S. Mahajan and G.Y. Chin: Acta Metall., 1973, vol. 21, pp. 173–9.

J.W. Christian and S. Mahajan: Prog. Mater. Sci., 1995, vol. 39, pp. 1–157.

I.J. Beyerlein, X. Zhang, and A. Misra: Annu. Rev. Mater. Res., 2014, vol. 44, pp. 329–63.

A. Serra and D.J. Bacon: Philos. Mag. A, 1996, vol. 73, pp. 333–43.

S. Jiang, Z. Jiang, and Q. Chen: Sci. Rep., 2019, vol. 9, pp. 1–5.

M.H. Yoo and J.K. Lee: Philos. Mag. A Phys. Condens. Matter, Struct. Defects Mech. Prop., 1991, vol. 63, pp. 987–1000.

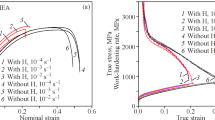

J. Kim, E. Plancher, and C.C. Tasan: Acta Mater., 2020, vol. 188, pp. 686–96.

H. Pfeiffer and H. Peisl: Phys. Lett. A., 1977, vol. 60, pp. 363–4.

M.E. Armacanqui and R.A. Oriani: Mater. Sci. Eng., 1987, vol. 92, pp. 127–32.

M. Gong, J.P. Hirth, Y. Liu, Y. Shen, and J. Wang: Mater. Res. Lett., 2017, vol. 5, pp. 449–64.

B. Li and E. Ma: Acta Mater., 2009, vol. 57, pp. 1734–43.

E.G. Astafurova, G.G. Zakharova, and H.J. Maier: Scr. Mater., 2010, vol. 63, pp. 1189–92.

I. V. Kireeva, Y.I. Chumlyakov, A. V. Tverskov, and H. Maier: Tech. Phys. Lett. https://doi.org/10.1134/S1063785011060071.

C. Hwang and I.M. Bernstein: Scr. Metall., 1982, vol. 16, pp. 85–90.

K. Lublinska, A. Szummer, and K.J. Kurzydlowski: in NATO Science for Peace and Security Series C: Environmental Security, vol. PartF2, Springer Verlag, 2008, pp. 757–64.

K. Lublinska, A. Szummer, and K.J. Kurzydlowski: Int. J. Nucl. Hydrog. Prod. Appl., 2008, vol. 1, p. 324.

H. Luo, Z. Li, and D. Raabe: Sci. Rep., 2017, vol. 7, p. 9892.

J.M. Rigsbee and R.B. Benson: J. Mater. Sci., 1977.

J. Yamabe, T. Matsumoto, S. Matsuoka, and Y. Murakami: Int. J. Fract., 2012, vol. 177, pp. 141–62.

R. Kirchheim and A. Pundt: in Physical Metallurgy: Fifth Edition, vol. 1, Elsevier Inc., 2014, pp. 2597–2705.

D. Ikuta, E. Ohtani, A. Sano-Furukawa, Y. Shibazaki, H. Terasaki, L. Yuan, and T. Hattori. https://doi.org/10.1038/s41598-019-43601-z.

Acknowledgments

The authors acknowledge the financial support by the U.S. Department of Energy’s Hydrogen and Fuel Cell Technologies Office within the Office of Energy Efficiency and Renewable Energy under award number DE-EE0008830, and the Department of the Navy, Office of Naval Research under ONR award number N00014-18-1-2284. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the Office of Naval Research. The authors would like to thank Shaolou Wei and Gaoming Zhu for their contributions.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 23, 2021, accepted October 10, 2021.

Appendix

Appendix

Grain boundary map of the sample before H charging, corresponding to the H charged sample in Fig. 5. Grain boundaries were mapped by EBSD. Σ3 boundaries are highlighted in blue, and high-angle GBs in cyan. Other CSL boundaries were non-existent except for the single Σ5 boundary shown in purple, which did not correspond to any martensite formation. Points colored black are not indexed due to low image quality in these regions

EBSD phase maps of a single sample (a) after 15 pct pre-strain, and (b) after 55 hours of H charging. (c) and (d) are EBSD twin parent-daughter maps of the same sample region after 55 hours of H charging, where (d) is an enlarged region from (c). Black pixels represent points of the EBSD scan with a confidence index lower than 0.02

EBSD inverse pole figure maps of a single sample, (a) before H charging, (b) after 55 hours H charging, and (c) after H desorption at room temperature for 180 days. (d) Orientation change after desorption measured at the 10 locations labeled in (a), which are points where twinning occurred in (b), i.e. 10 twin instances. Red data points in the graph mark orientation changes comparing (c) to (a), i.e., the change in orientation from the original material state to the desorbed state. Blue data points mark the orientation difference between (c) and (b), i.e., the orientation change from just after H is added to the material to the desorbed state

Rights and permissions

About this article

Cite this article

Ronchi, M.R., Yan, H. & Tasan, C.C. Hydrogen-Induced Martensitic Transformation and Twinning in Fe45Mn35Cr10Co10. Metall Mater Trans A 53, 432–448 (2022). https://doi.org/10.1007/s11661-021-06498-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06498-w