Abstract

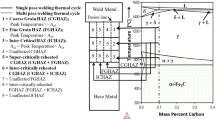

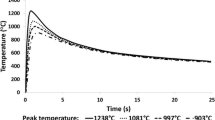

The present work characterized the 9 pct Ni steel heat-affected zone (HAZ). HAZ thermal cycles (peak temperatures—Tp—of 500 °C, 600 °C, 650 °C, 700 °C, 750 °C, 850 °C, 1100 °C, and 1370 °C) were numerically (FEM model) and physically (Gleeble machine) simulated. The simulated HAZ was evaluated through optical microscopy, scanning electron microscopy (SEM), X-ray diffraction (XRD), dilatometry, and Vickers hardness. Tp ≤ 650 °C had microstructure similar to base metal; Tp of 700 °C yielded the partial transformation (Ac1 < Tp < Ac3) and presence of ferrite and martensite; Tp > 750 °C yielded martensite (majority) with maximum hardness (344 HV10) for Tp = 850 °C. The amount of austenite was maximum (3.1 pct) to Tp = 700 °C and decreased to Tp ≥ 750 °C, becoming approximately zero for Tp ≥ 1100 °C. Besides, the austenite quantification methodology (electrolytic polished and 4 pct Picral etching + SEM image analysis) was validated through XRD measurement and used to analyze the roundness and number of austenite particle size of the BM and HAZ subzones. Its roundness and amount remained are close to the BM for Tp ≤ 650 °C, increase in the Tp = 700 °C, and decrease for Tp ≥ 750 °C.

Similar content being viewed by others

References

ASTM A333-16: Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service and other Application Toughness, ASTM International West Conshohocken, PA, USA, 2015.

American Society for Mechanical Engineers (ASME). Boiler and Pressure Vessel Code, Section VIII, Division 1: Design and Fabrication of Pressure Vessels, 2007.

ASTM A553-10 Standard Specification for Pressure Vessel Plates, Alloy Steel, Quenched and Tempered 8 and 9 pct Nickel, (2010) (West Conshohocken, United States).

J.R. Strife and D.E. Passoja: Metall. Mater. Trans. A., 1980, vol. 11A, pp. 1341–50. .

S.S.M. Tavares, C.R. Rodrigues, C.A.S. de Oliveira, C.B. Woyames, and J. Dille: J. Mater. Eng. Perform., 2018, vol. 27, pp. 1530–6. .

S. Hany, B. Duponchel, C. Poupin, A.A. Kais, D. Dewael, J.-B. Vogt, J. Bouquerel, H. Kacem, A. Mouftiex, S. Hariri, M. Milochova, E. Bychkov, and E.A. Aad: Adv. Mater. Res., 2014, vol. 936, pp. 1953–7. .

S.S.M. Tavares, M.L. Laurya, H.N. Farneze, R.V. Landim, J.A.C. Velasco, and J.L.M. Andia: Eng. Fail. Anal., 2019, vol. 104, pp. 331–40. .

Q. Ahsan and A.S.M.A. Haseeb: Compr. Mater. Process., 2014, vol. 6, pp. 135–49. .

A.V. Passos, F.W.C. Farias, V.H.P.M. Oliveira, M.C.G. Rios, and J.C. Payão Filho: Constr. Build. Mater., 2020, vol. 282, p. 122573. .

M. Kappes, M. Iannuzzi, R.B. Rebak, and R.M. Carranza: Corrosion Review., 2014, vol. 32, pp. 101–28. .

Y.H. Yang, Q.W. Cai, D. Tang, and H.B. Wu: Metall. Mater., 2010, vol. 17, pp. 587–95. .

K.J. Kim and L.H. Schwartz: Mater. Sci. Eng., 1978, vol. 33, pp. 5–20. .

E. Nippes and J. Balaguer: Welding Res. Suppl., 1986, vol. 57, pp. 237–43. .

E.J. Barrick and J.D. DuPont: Mater. Sci. Eng. A., 2019, vol. 748, pp. 198–204. .

J.M. Zhang, H. Li, F. Yang, Q. Chi, L.K. Ji, and Y.R. Feng: J. Mater. Eng. Perform., 2013, vol. 22, pp. 3867–71. .

Z. Xi-Qing, P. Tao, W. Qing-Feng, S. Hang, Y. Cai-Fu, and Y. Qing-Xiang: J. Iron Steel Res., 2011, vol. 18, pp. 47–51. .

G.R. Brophy and A.J. Miller: Trans. Am. Soc. Metals., 1948, vol. 41, pp. 1185–202. .

T. Zhang, W. Zhao, Q. Deng, W. Jiang, Y. Wang, Y. Wang, and W. Jiang: Int. J. Hydrogen Energy., 2017, vol. 42, pp. 25102–13. .

V.S. Fernandes, F.W.C. Farias, and J.C. Payão Filho: J. Mater. Res. Technol., 2020, vol. 9, pp. 6305–21. .

W. Liu, F. Lu, R. Yang, X. Tang, and H. Cui: J. Mater. Process. Technol., 2015, vol. 225, pp. 221–8. .

L. Wang, Z. Liu, Z. Cui, C. Du, X. Wang, and X. Li: Corros. Sci., 2014, vol. 85, pp. 401–10. .

L. Lan, C. Qiu, D. Zhao, X. Gao, and L. Du: Mater. Sci. Eng. A., 2011, vol. 529, pp. 192–200. .

G.R. Goodall, J. Gianetto, J. Bowker, and M. Brochu: Can. Metall. Q., 2011, vol. 51, pp. 58–66. .

L. Lan and G. Shao: Micron., 2020, vol. 131, p. 102828. .

P.S. Myers, O.A. Uyehara, and G.L. Borman: Fundamentals of heat flow in welding. Welding Research Council, New York, 1967.

L.-E. Lindgren: J. Therm. Stress., 2006, vol. 24, pp. 141–92. .

A. Anca, A. Cardona, J. Risso, and V.D. Fachinotti: Appl. Math. Model., 2011, vol. 35, pp. 688–707. .

G. Genchev, O. Dreibati, R. Ossenbrink, N. Doynov, and V. Michailov: Mater. Sci. Forum., 2013, vol. 762, pp. 544–50. .

J. Goldak, M. Bibby, J. Moore, R. House, and B. Patel: Metall. Trans. B., 1986, vol. 17B, pp. 587–600. .

W. Hackenhaar, A.R. Gonzalez, I.G. Machado, and J.A.E. Mazzaferro: Int. J. Adv. Manuf. Technol., 2018, vol. 94, pp. 497–507. .

J.A. Siefert, B.M. Leister, and J.N. DuPont: Mater. Sci. Technol., 2015, vol. 31, pp. 651–60. .

American Society for Testing and Materials (ASTM). A1033-10: Standard Practice for Quantitative Measurement and Reporting of Hypoeutectoid Carbon and Low-alloy Steel Phase Transformations. West Conshohocken, Philadelphia, 2011.

American Society for Testing and Materials (ASTM). E112-13: Standard Test Methods for Determining Average Grain Size, ASTM International, West Conshohocken, Philadelphia, 2013.

H.M. Rietveld: J. Appl. Crystallogr., 1969, vol. 2, pp. 65–71. .

American Society for Testing and Materials (ASTM). E92: Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials, ASTM International, West Conshohocken, Philadelphia, 2017.

R.R. Mohanty, O.A. Girina, and N.M. Fonstein: Metall. Mater. Trans. A., 2011, vol. 42A, pp. 3680–90. .

K.A. AlOgab, D.K. Matlock, J.G. Speer, and H.J. Kleebe: ISIJ Int., 2007, vol. 47, pp. 1034–41. .

T. Pan, J. Zhu, and C.F. Yang: Rare Met., 2015, vol. 34, pp. 776–82. .

A. Ebrahimian and S.S.G. Banadkouki: J. Alloys Compd., 2017, vol. 708, pp. 43–54. .

H.K.D.H. Bhadeshia, L.-E. Svensson: Modelling the evolution of microstructure of steel weld metal. Mathematical Modelling of Weld Phenomena, eds. H. Cerjak, K.E. Easterling, Institute of Materials, London, 1993.

G. Jahrsengene, M. Wenn, M. Karlsen, I. Westermann, O.M. Akselsen, J. Hjelen: EBSD quantification of retained austenite in 9 pct Ni steel related to thermal treatments. International Society of Offshore and Polar Engineers, Trondheim, Norway, unpublished research, 2015.

J.B. Leblond and J. Devaux: Acta Metall., 1984, vol. 32, pp. 137–46. .

H.K.D.H. Bhadeshia, E. Keehan, L. Karlsson, and H.O. Andrén: Trans. Indian Inst. Met., 2006, vol. 59, pp. 689–94. .

E. Keehan, L. Karlsson, H.O. Andrén, H.K.D.H. Bhadeshia: Understanding mechanical properties of novel high strength steel weld metals through high-resolution microstructural investigations. in International Conference: Trends in Welding Research. Atlanta, Georgia, USA: ASM International, 2005.

M. Shome, O.P. Gupta, and O.N. Mohanty: Metall. Mater. Trans. A., 2004, vol. 35, pp. 985–96. .

K. Tsuzaki, K. Fujiwara, and T. Maki: Mater. Trans., 1991, vol. 32, pp. 667–78. .

B. Fultz, C.K. Syn, and J.W. Morris: Metall. Mater. Trans. A., 1985, vol. 16A, pp. 2251–6. .

L. Reimer: Scanning Electron Microscopy. 2nd ed. Springer, New York, 1998.

M. Hayakawa, S. Matsuoka, and K. Tsuzaki: Mater. Trans., 2002, vol. 43, pp. 1758–66. .

Acknowledgments

The authors thank Vallourec Soluções Tubulares do Brasil S. A. (Vallourec) for their donation of the 9 pct Ni steel pipe and the Brazilian Nanotechnology National Laboratory (LNNano) and the National Institute of Technology (INT) for the X-ray diffraction and scanning electron microscopy analyses, respectively.

Author Contributions

MCGR: conceptualization, methodology, validation, investigation, and writing—original draft. JCPF: methodology, investigation, writing—review and editing, and supervision. FWCF: conceptualization, methodology, validation, investigation, writing—original draft. VHPMO: conceptualization, software, methodology, and validation. AVP: conceptualization, methodology, and investigation.

Funding

This work was funded by Shell Brasil Petróleo Ltda. (Shell Brasil), formerly British Gas (BG Group), and Empresa Brasileira de Pesquisa e Inovação Industrial (Embrapii), Grants (TO821) and PCCOP1512.0004, respectively, and was supported by the Agência Nacional de Petróleo, Gás Natural e Biocombustíveis (ANP).

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted January 14, 2021, accepted August 21, 2021.

Rights and permissions

About this article

Cite this article

Rios, M.C.G., Payão Filho, J.C., Farias, F.W.C. et al. Microstructural Characterization of the Simulated Heat-Affected Zone of 9 Pct Ni Steel. Metall Mater Trans A 52, 5016–5031 (2021). https://doi.org/10.1007/s11661-021-06446-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06446-8