Abstract

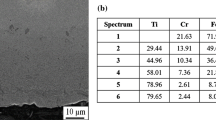

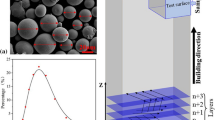

In this study, the effect of the microstructure of a titanium alloy substrate fabricated using selective layer melting (SLM) on a microarc oxidation (MAO) film was studied by comparing it with a forging substrate. The microstructure, thickness, and composition of the MAO coating obtained on the different substrates were detected by scanning electron microscopy, a coating thickness meter, energy-dispersive spectroscopy, and X-ray diffraction, respectively. The corrosion behavior of the MAO coating was evaluated using potentiodynamic polarization tests. The results showed that the SLM substrate presented a dense microstructure composed of fine acicular martensite α′ and coarse α phases, which included many defects such as dislocations, twins, and grain boundaries. The microstructure supplied many discharge channels, allowing electrons and anions to pass easily, thus reducing the breakdown voltage of the anode oxide film. It also significantly improved the voltage increase rate of the MAO film in the range of 600 to 1800 seconds and decreased the difficulty of microarc nucleation. The SLM-MAO film was thicker than the Forging-MAO film, and the TiO2 amorphous region of the SLM-MAO film was uniform. Moreover, many P elements were present in the SLM-MAO film. After MAO treatment, the SLM-MAO film exhibited better corrosion resistance.

Similar content being viewed by others

References

W.F. Xu, J. Ma, Y.X. Luo, and Y.X. Fang: Trans. Nonferrous Met. Soc. China., 2020, vol. 30, pp. 160–70. .

A. Gao, R.Q. Hang, L. Bai, B. Tang, and P.K. Chu: Electrochim. Acta., 2018, vol. 271, pp. 699–718. .

T.T. Oliveir and A.C. Reis: J. Prosthet. Dent., 2019, vol. 122, pp. 270–4. .

D. Leordean, S.A. Radu, D. Frăţilă, and P. Berce: Int. J. Adv. Manuf. Technol., 2015, vol. 79, pp. 905–20. .

P. Kürnsteiner, M.B. Wilms, A. Weisheit, P. Barriobero-Vila, B. Gault, E. Aimé Jägle, and D. Raabe: J. Microsc. Soc. Am., 2017, vol. 23(S1), pp. 694–5. .

F. Lv, H.X. Liang, D.Q. Xie, Y.Y. Mao, C.J. Wang, L.D. Shen, and Z.J. Tian: J. Alloys Compd., 2021, vol. 854, p. 156688. .

H.W. Zhang, C. Man, C.F. Dong, L.W. Wang, W. Li, D.C. Kong, L. Wang, and X. Wang: Corros. Sci., 2021, vol. 179, p. 109097. .

A. Sharma, M.C. Oh, J.T. Kim, A.K. Srivastava, and B. Ahn: J. Alloys Compd., 2020, vol. 830, p. 154620. .

S. Pal, G. Lojen, R. Hudak, V. Rajtukova, T. Brajlih, V. Kokol, and I. Drstvenšeka: Addit. Manuf., 2020, vol. 33, p. 101147. .

S.F. Liu, S. Han, L. Zhang, L.Y. Chen, L.Q. Wang, L. Zhang, Y.J. Tang, J. Liu, H.P. Tang, and L.C. Zhang: Compos. B., 2020, vol. 200, p. 108358. .

N. Hafeez, J. Liu, L.Q. Wang, D.X. Wei, Y.J. Tang, W.J. Lua, and L.C. Zhang: Addit. Manuf., 2020, vol. 34, p. 101264. .

S. Dadbakhsh, R. Mertens, L. Hao, J. Van Humbeeck, and J.P. Kruth: Adv. Eng. Mater., 2019, vol. 21, p. 180124. .

M. Qadir, Y.C. Li, K. Munir, and C.E. Wen: Crit. Rev. Solid State Mater. Sci., 2018, vol. 43, pp. 392–416. .

L.Y. Cui, S.D. Gao, P.P. Li, R.C. Zeng, F. Zhang, S.Q. Li, and E.H. Han: Corros. Sci., 2017, vol. 118, pp. 84–95. .

C. Marinescu, M.B. Ali, A. Hamdi, Y. Cherifi, A. Barras, Y. Coffinier, S. Somacescu, V. Raditoiu, S. Szunerits, and R. Boukherroubb: Chem. Eng. J., 2018, vol. 336, pp. 465–75. .

M.S. Vasilyeva, V.S. Rudnev, A.A. Zvereva, A.Y. Ustinov, O.D. Arefieva, V.G. Kuryavyi, and G.A. Zverev: J. Photochem. Photobiol. A., 2018, vol. 356, pp. 38–45. .

X.P. Lu, M. Mohedano, C. Blawert, E. Matykina, R. Arrabal, K.U. Kainer, and M.L. Zheludkevich: Surf. Coat. Technol., 2016, vol. 307, pp. 1165–82. .

J.H. Yao, Y. Wang, G.L. Wu, M. Sun, M. Wang, and Q.L. Zhang: Appl. Surf. Sci., 2019, vol. 479, pp. 727–37. .

X.C. Yan, C.Y. Chen, R. Bolof, W.Y. Ma, C.M. Deng, J. Wang, Z.M. Ren, H.L. Liao, and M. Liu: Mater. Res. Express., 2019, vol. 6, p. 096509. .

B. Ren, Y. Wan, C. Liu, H.W. Wang, M.Z. Yu, X. Zhang, and Y. Huang: Mater. Sci. Eng. C., 2021, vol. 118, p. 111505. .

G.B. Darband, M. Aliofkhazraei, P. Hamghalam, and N. Valizade: J. Magnes. Alloys., 2017, vol. 5, pp. 74–132. .

H. Sharifi, M. Aliofkhazraei, G.B. Darband, and S. Shrestha: Surf. Rev. Lett., 2018, vol. 25, p. 1830004. .

L.Y. An, Y. Ma, Y.P. Liu, L. Sun, S. Wang, and Z.Y. Wang: Surf. Coat. Technol., 2018, vol. 354, pp. 226–35. .

Z. Husaain, A. Ahmed, O.M. Irfan, and F. Al-Mufadi: Int. J. Eng. Technol., 2017, vol. 9, pp. 426–31. .

D.Y. Wang, Q. Dong, C.Z. Chen, and T.Q. Lei: Guisuanyan Xuebao., 2005, vol. 33, pp. 1133–8. .

L.E. Murr, S.A. Quinones, S.M. Gaytan, M.I. Lopez, A. Rodela, E.Y. Martinez, D.H. Hernandez, E. Martinez, F. Medina, and R.B. Wicker: J. Mech. Behav. Biomed. Mater., 2009, vol. 58, pp. 20–32. .

A. Matthias, W. Mirwaes, B. Christian, K. Kristian, W. Gerd, B.V. Pere, R. Guillermo, B. Ulrike, and F. Gerald: J. Synchrotron Radiat., 2016, vol. 23, pp. 579–89. .

L. Thijs, F. Verhaeghe, T. Craeghs, J.V. Humbeeck, and J.P. Kruth: Acta Mater., 2010, vol. 58, pp. 3303–12. .

M. Stern and A.L. Geary: J. Electrochem. Soc., 1957, vol. 104, pp. 56–63. .

A.L. Yerokhin, X. Nie, A. Leyland, and A. Matthews: Surf. Coat. Technol., 2000, vol. 130, pp. 195–206. .

R.O. Hussein, X. Nie, D.O. Northwood, A. Yerokhin, and A. Matthews: J. Phys. D: Appl. Phys., 2010, vol. 43, pp. 105203–16. .

S.C. Troughton, A. Nomine, J. Dean, and T.W. Clyne: Appl. Surf. Sci., 2016, vol. 389, pp. 260–9. .

L. Yerokhin, L.O. Snizhko, N.L. Gurevina, A. Leyland, A. Pilkington, and A. Matthews: J. Phys. D: Appl. Phys., 2003, vol. 36, pp. 2110–20. .

S. Fatimah, H.W. Yang, M.P. Kamil, and Y.G. Ko: Appl. Surf. Sci., 2019, vol. 477, pp. 60–70. .

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 14, 2021; accepted July 29, 2021.

Rights and permissions

About this article

Cite this article

Wang, H., Zhai, D. & Feng, K. Effect of the Microstructure of a Titanium Alloy Fabricated Using Selective Laser Melting on Microarc Oxidation Film. Metall Mater Trans A 52, 4691–4702 (2021). https://doi.org/10.1007/s11661-021-06421-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06421-3