Abstract

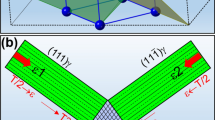

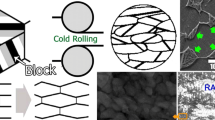

The present work investigates the effect of double-pass deformation and annealing on the evolution of NbC precipitates during hot deformation of a Fe-30Ni-Nb microalloyed model steel. The investigation has been performed using transmission electron microscopy. NbC precipitation mainly took place on the periodic dense dislocation networks constituting the microband (MB) walls that largely maintained their crystallographic alignment up to large strains. The double-pass deformation has markedly reduced the precipitate size compared to the equivalent single-pass straining despite twice as long post-deformation annealing time. This has largely been attributed to relocation of the precipitates at the second pass to solute-richer areas, which shifts the precipitation process back to the nucleation and growth stage, and to particle rotations that disrupt their (semi-)coherency with austenite and thus restrict their growth due to increased misfit stresses. The extended holding after two-pass deformation did not increase the precipitate size due to widespread dislocation annihilation through recovery processes, leading to coarsening and disintegration of the MB wall dislocation networks. This resulted in decreased efficacy of the pipe diffusion and complete loss of access to this type of diffusion for a large fraction of precipitates, which markedly hindered the precipitation growth and coarsening processes.

Similar content being viewed by others

References

I. Tamura, H. Sekine, T. Tanaka, and C. Ouchi: Thermomechanical Processing of High Strength Low Alloy Steels. Butterworth-Heinemann, London, 1988.

T. Gladman: The Physical Metallurgy of Microalloyed Steels. Maney Materials Science, London, 2002.

A.J. DeArdo, M.J. Hua, K.G. Cho, and C.I. Garcia: Mater. Sci. Technol., 2009, vol. 25, pp. 1074–82.

D.Q. Bai, S. Yue, W.P. Sun, and J.J. Jonas: Metall. Mater. Trans. A., 1993, vol. 24A, pp. 2151–9.

G. Li, T.M. Maccagno, D.Q. Bai, and J.J. Jonas: ISIJ Int., 1996, vol. 36, pp. 1479–85.

K.B. Kang, O. Kwon, W.B. Lee, and C.G. Park: Scr. Mater., 1997, vol. 36, pp. 1303–8.

S.F. Medina, A. Quispe, P. Valles, and J.L. Baños: ISIJ Int., 1999, vol. 39, pp. 913–22.

S.F. Medina and A. Quispe: Mater. Sci. Technol., 2000, vol. 16, pp. 635–42.

R. Abad, A.I. Fernández, B. López, and J.M. Rodriguez-Ibabe: ISIJ Int., 2001, vol. 41, pp. 1373–82.

H.S. Zurob, Y. Brechet, and G. Purdy: Acta Mater., 2000, vol. 49, pp. 4183–90.

H.S. Zurob, C.R. Hutchinson, Y. Brechet, and G. Purdy: Acta Mater., 2002, vol. 50, pp. 3075–92.

H.S. Zurob, C.R. Hutchinson, Y. Brechet, and G. Purdy: Mater. Sci. Eng. A., 2004, vol. 382, pp. 64–81.

C. Klinkenberg, K. Hulka, and W. Bleck: Steel Res., 2004, vol. 75, pp. 744–52.

S. Vervynckt: Control of the non-recrystallization temperature in high strength low alloy (HSLA) steels, PhD thesis, Ghent University, Gent, Belgium, 2010.

S. Vervynckt, K. Verbeken, P. Thibaux, and Y. Houbaert: Mater. Sci. Eng. A., 2011, vol. 528, pp. 5519–28.

S. Vervynckt, K. Verbeken, B. Lopez, and J.J. Jonas: Int. Mater Rev., 2012, vol. 57, pp. 187–207.

B. Dutta and C.M. Sellars: Mater. Sci. Technol., 1987, vol. 3, pp. 197–206.

B. Dutta, E. Valdes, and C.M. Sellars: Acta Metall. Mater., 1992, vol. 40, pp. 653–62.

B. Dutta, E.J. Palmiere, and C.M. Sellars: Acta Mater., 2001, vol. 49, pp. 785–94.

W.M. Rainforth, M.P. Black, R.L. Higginson, E.J. Palmiere, C.M. Sellars, I. Prabst, P. Warbichler, and F. Hofer: Acta Mater., 2002, vol. 50, pp. 735–47.

E.J. Palmiere, P. Cizek, F. Bai, R.M. Poth, J. Turner, B.P. Wynne, and W.M. Rainforth: Mater. Manuf. Process., 2011, vol. 26, pp. 127–31.

Z. Guo and A.P. Miodownik: Mater. Sci. Forum., 2011, vol. 706–709, pp. 2728–33.

Y. Luo, J. Zhang, and C. Xiao: Steel Res. Int., 2012, vol. 83, pp. 238–43.

C.M. Sellars and E.J. Palmiere: Mater. Sci. Forum., 2005, vol. 500–501, pp. 3–14.

V. Nagarajan, E.J. Palmiere, and C.M. Sellars: Mater. Sci. Technol., 2009, vol. 25, pp. 1168–74.

P. Cizek, F. Bai, E.J. Palmiere, and W.M. Rainforth: J. Microsc., 2005, vol. 217, pp. 138–51.

H. Beladi, P. Cizek, and P.D. Hodgson: Metall. Mater. Trans., 2009, vol. 40A, pp. 1175–89.

H. Beladi, P. Cizek, and P.D. Hodgson: Acta Mater., 2010, vol. 58, pp. 3531–41.

A.S. Taylor, P. Cizek, and P.D. Hodgson: Acta Mater., 2011, vol. 59, pp. 5832–44.

A.S. Taylor, P. Cizek, and P.D. Hodgson: Acta Mater., 2012, vol. 60, pp. 1548–69.

D. Poddar, P. Cizek, H. Beladi, and P.D. Hodgson: Metall. Mater. Trans. A., 2015, vol. 46A, pp. 5933–51.

D. Poddar, P. Cizek, H. Beladi, and P.D. Hodgson: Mater. Charact., 2016, vol. 118, pp. 382–96.

D. Poddar, P. Cizek, H. Beladi, and P.D. Hodgson: Acta Mater., 2014, vol. 80, pp. 1–15.

D. Poddar, P. Cizek, H. Beladi, and P.D. Hodgson: Acta Mater., 2015, vol. 99, pp. 347–62.

D. Poddar, Interaction between Precipitation and Dislocation Substructure in a Model Microalloyed Steel, PhD Thesis, Deakin University, 2015.

D.B. Williams and C.B. Carter: Transmission Electron Microscopy—A Textbook for Materials Science. Springer, New York, 2009.

Acknowledgments

Financial support provided by the Australian Research Council is gratefully acknowledged. The Deakin University’s Advanced Characterisation Facility is thanked for provision of the research facilities used in the present work. DP would like to thank Tata Steel Ltd. (R&D) for the encouragement to publish this work.

Conflict of interest

No conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 8, 2021; accepted July 6, 2021.

Rights and permissions

About this article

Cite this article

Poddar, D., Cizek, P., Beladi, H. et al. The Effect of Strain and Annealing on the Growth of NbC Precipitates During Two-Pass Hot Deformation of a Fe-30Ni-Nb Model Microalloyed Steel. Metall Mater Trans A 52, 4357–4367 (2021). https://doi.org/10.1007/s11661-021-06388-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06388-1