Abstract

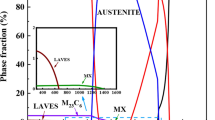

The carbide precipitation, microstructure evolution, and tensile properties of Fe-30Mn-0.14C-7Cr-0.26Ni (in wt pct) steel after cold rolling to 95 pct reduction followed by annealing at temperatures ranging from 600 °C to 900 °C for 1 hour were investigated. The results show that, when the annealing temperature is increased from 600 °C to 900 °C, the grain size increases from 0.65 ± 0.30 to 5.75 ± 3.87 μm. When the annealing temperature is 600 °C, Cr23C6 carbides begin to precipitate. When the annealing temperature is increased from 600 °C to 800 °C, the average size of carbides increases from 39 to 69 nm. When the annealing temperature is increased to 900 °C, no carbides are produced due to the increased solubility of C in the austenite matrix. Ultrafine grains (~ 0.8 ± 0.58 μm) with a large amount of nanoscale carbides (~ 53 ± 21.8 nm) were obtained after annealing at 700 °C, resulting in a good combination of yield strength (679 MPa) and total elongation (38.4 pct). The fraction of deformation twins within the samples under different tensile strains was calculated, and it was revealed that grain refinement can seriously inhibit the generation of deformation twins. In addition, it has been found that grain refinement strengthening, precipitation strengthening, and dislocation strengthening have significant effects on yield strength, while the effects of solution strengthening and lattice friction are relatively weaker.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

O. Grässel, L. Krüger, G. Frommeyer, and L.W. Meyer: Int. J. Plast., 2000, vol. 16, pp. 1391–1409.

C. Haase, S.G. Chowdhury, L.A. Barrales-Mora, D.A. Molodov, and G. Gottstein: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 911–22.

O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, and D. Barbier: Curr. Opin. Solid State Mater. Sci., 2011, vol. 15, pp. 141–68.

Y. Lü, D.A. Molodov, and G. Gottstein: Acta Mater., 2011, vol. 59, pp. 3229–43.

M. Koyama, Y. Shimomura, A. Chiba, E. Akiyama, and K. Tsuzaki: Scripta Mater., 2017, vol. 141, pp. 20–23.

J. Hufenbach, F. Kochta, H. Wendrock, A. Voss, L. Giebeler, S. Oswald, S. Pilz, U. Kühn, A. Lode, M. Gelinsky, and A. Gebert: Mater. Des., 2018, vol. 142, pp. 22–35.

L. Bracke, K. Verbeken, L. Kestens, and J. Penning: Acta Mater., 2009, vol. 57, pp. 1512–24.

H. Li, F. Yin, T. Sawaguchi, K. Ogawa, X. Zhao, and K. Tsuzaki: Mater. Sci. Eng. A, 2008, vol. 49, pp. 4217–26.

V. Shterner, I.B. Timokhina, and H. Beladi: Mater. Sci. Eng. A, 2016, vol. 669, pp. 437–46.

I. Gutierrez-Urrutia and D. Raabe: Acta Mater., 2012, vol. 60, pp. 5791–5802.

K. Renard and P.J. Jacques: Mater. Sci. Eng. A, 2012, vol. 542, pp. 8–14.

H.Z. Wang, P. Yang, W.M. Mao, and F.Y. Lu: J. Alloys Compds., 2013, vol. 558, pp. 26–33.

J.B. Seol, J.E. Jung, Y.W. Jang, and C.G. Park: Acta Mater., 2013, vol. 61, pp. 558–78.

V. Shterner, I.B. Timokhina, and H. Beladi: Adv. Mater. Res., 2014, vol. 922, pp. 676–81.

S. Allain, J.P. Chateau, and O. Bouaziz: Mater. Sci. Eng. A, 2004, vols. 387–389, pp. 143–47.

K.-T. Park, K.G. Jin, S.H. Han. S.W. Hwang, K. Choil, and C.S. Lee: Mater. Sci. Eng. A, 2010, vol. 527, pp. 3651–61.

S. Allain, O. Bouaziz, and J.P. Chateau: Scripta Mater., 2010, vol. 62, pp. 500–03.

S.I. Lee, S. Y. Lee, J. Han, and B. Hwang: Mater. Sci. Eng. A, 2019, vol. 742, pp. 334–43.

K.M. Rahman, V.A. Vorontsov, and D. Dye: Acta Mater., 2015, vol. 89, pp. 247–57.

M. Koyama, T. Sawaguchi, and K. Tsuzaki: Mater. Sci. Eng. A, 2011, vol. 530, pp. 659–63.

I. Gutierrez-Urrutia, S. Zaefferer, and D. Raabe: Mater. Sci. Eng. A, 2010, vol. 527, pp. 3552–60.

S. Kang, J.G. Jung, M. Kang, W. Woo, and Y.K. Lee: Mater. Sci. Eng. A, 2016, vol. 652, pp. 212–20.

B.C. De Cooman, Y. Estrin, and S.K. Kim: Acta Mater., 2018, vol. 142, pp. 283–362.

T. Yang, Y.L. Zhao, Y. Tong, Z.B. Jiao, J. Wei, J.X. Cai, X.D. Han, D. Chen, A. Hu, J. J. Kai, K. Lu, Y. Liu, and C.T. Liu: Science, 2018, vol. 362, pp. 933–37.

K. Zhang, H.Y. Wen, B.B. Zhao, X.P. Dong, and L.T. Zhang: Mater. Charact., 2019, vol. 155, p. 109792.

C. Scott, B. Remy, J.-L. Collet, A. Cael, C. Bao, F. Danoix, B. Malard, and C. Curfs: Int. J. Mater. Res., 2011, vol. 102, pp. 538–49.

H. Kubo, K. Nakamura, S. Farjami, and T. Maruyama: Mater. Sci. Eng. A, 2004, vol. 378, pp. 343–48.

Y. Yazawa, T. Furuhara, and T. Maki: Acta Mater., 2004, vol. 52, pp. 3727–36.

K.H. Han: Mater. Sci. Eng. A, 2000, vol. 279, pp. 1–9.

S. Kajiwara, D.Z. Liu, T. Kikuchi, and N. Shinya: Scripta Mater., 2001, vol. 44, pp. 2809–14.

J. Moon, H.-Y. Ha, S.-J. Park, T.-H. Lee, J.H. Jang, C.-H. Lee, H.N. Han, and H.-U. Hong: J. Alloys Compds., 2019, vol. 775, pp. 1136–46.

Y.S. Zhang, X.M. Zhu, and S.H. Zhong: Corr. Sci., 2004, vol. 46, pp. 853–76.

S.S.M. Tavares, M.L. Laurya, H.N. Farneze, R.V. Landim, J.A.C. Velasco, and J.L.M. Andia: Eng. Fail. Anal., 2019, vol. 104, pp. 331–40.

X.M. Chen, Y.H. Wang, J.C. Xiong, G.Y. Li, Y.Z. Tian, W.Q. Cao, and T.S. Wang: Front. Mater., 2020, vol. 7.

Y.H. Wang, J.M. Kang, Y. Peng, T.S. Wang, N. Hansen, and X.X. Huang: Scripta Mater., 2018, vol. 155, pp. 41–45.

S. Deb, S.K. Panigrahi, and M. Weiss: Mater. Charact., 2019, vol. 154, pp. 80–93.

K. Maruyama, K. Sawada, and J.-I. Koike: ISIJ Int., 2001, vol. 41, pp. 641–53.

M. Roussel, X. Saurage, M. Perez, D. Magné, A. Hauet, A. Steckrneyer, M. Vermont, T. Chaise, and M. Couvrat: Materials, 2018, vol. 4, pp. 331–39.

S.H. Byun, N. Kang, T.H. Lee, S.K. Ahn, H.W. Lee, W.S. Chang, and K.M. Cho: Metall. Mater. Int., 2012, vol. 18, pp. 201–07.

Y.M. He, Y.H. Wang, K. Guo, and T.S. Wang: Mater. Sci. Eng. A, 2017, vol. 708, pp. 248–53.

K. Kaneko, T. Fukunaga, K. Yamada, N. Nakada, M. Kikuchi, Z. Saghi, J.S. Barnard, and P.A. Midgley: Scripta Mater., 2011, vol. 65, pp. 509–12.

Y.H. Wang, B.D. Shi, Y.M. He, H.W. Zhang, Y. Peng, and T.S. Wang: Materials, 2018, vol. 11, pp. 253–61.

Y.H. Wang, J.M. Kang, Y. Peng, T.S. Wang, N. Hansen, and X.X. Huang: J. Mater. Sci. Technol., 2018, vol. 34, pp. 229–33.

S. Curtze, V.T. Kuokkala, A. Oikari, J. Tälonen, and H. Hänninen: Acta Mater., 2011, vol. 59, pp. 1068–76.

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and N. Guelton: Mater. Sci. Eng. A, 2004, vol. 387, pp. 158–62.

O. Bouaziz and N. Guelton: Mater. Sci. Eng. A, 2001, vols. 319–321, pp. 246–49.

P.J. Brofman and G.S. Ansell: Metall. Mater. Trans. A, 1978, vol. 9A, pp. 879–80.

W.S. Yang and C.M. Wan: J. Mater. Sci., 1990, vol. 25, pp. 1821–23.

L. Lin, T.Y. Hsu, and Y Zu: Calphad, 1997, vol. 21, pp. 443–48.

A.S. Hamada, L.P. Karjalainen, and M.C. Somani: Mater. Sci. Eng. A, 2007, vol. 467, pp. 114–24.

P. Kusakin, A. Belyakov, C. Haase, R. Kaibyshev, and D.A. Molodov: Mater. Sci. Eng. A, 2014, vol. 617, pp. 52–60.

J.P. Chateau, A. Dumay, S. Allain, and A.J. Jacques: JPCS, 2010, vol. 240, p. 012023.

X. Wang, H.S. Zurob, J.D. Embury, X. Ren, and I. Yakubtsov: Mater. Sci. Eng. A, 2010, vol. 527, pp. 3785–91.

H. Wu, S. Huang, C.Y. Zhu, H.G. Zhu, and Z.H. Xie: Prog. Nat. Sci. Mater., 2020, vol. 30, pp. 239–45.

X.J. Wang, X.J. Sun, C. Song, H. Chen, W. Han, and F. Pana: Mater. Sci. Eng. A, 2017, vol. 698, pp. 110–16.

X.Z. Zhang, T.J. Chen, and Y.H. Qin: Mater. Des., 2016, vol. 99, pp. 182–92.

Environmental Chemistry, J.K. Barbalace Inc., 1995, https://environmentalchemistry.com/yogi/perioc, Accessed 22 Oct 1995.

H.H. Zhi, C. Zhang, S. Antonov, H.Y. Yu, T. Guo, and Y.J. Su: Acta Mater., 2020, vol. 195, pp. 371–82.

M. Sauzay and L.P. Kubin: Progr. Mater. Sci., 2011, vol. 56, pp. 725–84.

N. Gao and T.N. Baker: ISIJ, 1988, vol. 38, pp. 144–51.

P. Kusakin, A. Belyakov, D.A. Molodov, and R. Kaibyshev: Mater. Sci. Eng. A, 2017, vol. 687, pp. 82–84.

Acknowledgments

The authors gratefully acknowledge the support from the National Nature Science Foundation of China (Grant Nos. 51871194 and 52001274) and the National Natural Foundation of Hebei Province, China (Grant No. E2018203312). One of the authors (YZ) acknowledges the support from the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation programme (Grant Agreement No 788567, M4D).

Data Availability

The data sets generated for this study are available upon request from the corresponding author.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 20, 2021; accepted May 30, 2021.

Rights and permissions

About this article

Cite this article

Chen, X., Zhang, J., Xiong, J. et al. Microstructure Evolution and Tensile Properties of Cold-Rolled and Annealed Fe-30Mn-0.14C-7Cr-0.26Ni Steel. Metall Mater Trans A 52, 3839–3848 (2021). https://doi.org/10.1007/s11661-021-06345-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06345-y