Abstract

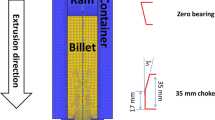

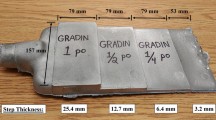

Porthole die extrusion is used to produce complex hollow aluminum cross-sections for automotive applications. In a porthole die, the material is first divided into multiple streams which are separated by a bridge, before rejoining in the weld chamber and finally passing through the die orifice. The rejoining of the material in the weld chamber produces lines known as weld lines in the final extruded product. The microstructure along the weld line and its associated quality are strongly influenced by the thermal-mechanical history the material experiences as it passes through the portholes, the weld chamber, and the die orifice, which can be altered by die design and, in particular, the bridge geometry. To study the influence of bridge geometry on weld line microstructure and final quality, a series of porthole die extrusion experiments was conducted using an Al–Mg–Si–Mn–Cr alloy and two different types of bridge geometry (streamlined and flat). The experimental results showed that bridge geometry had a significant effect on the local microstructure and crystallographic texture at the weld line. Specifically, EBSD analysis indicated that the weld line texture associated with a streamlined bridge geometry consisted of a deformation texture (mainly the copper component), while the local texture produced by a flat bridge was a recrystallization texture consisting of Cube, Goss, and CubeRD texture components. Simulation of the extrusion process, using DEFORM 3D, indicated that the weld line produced using a flat bridge experienced a slightly higher temperature, but much higher equivalent strains than the streamlined case. Material away from the weld line was very similar for both cases, indicating that the effect of the die bridge geometry is localized to the region close to the weld line.

Similar content being viewed by others

References

B. Lynn and J. Joe, Aluminum Extrusion Aids Auto Lightweighting. (Design News, 2015), https://cdn.ymaws.com/sites/aec.site-ym.com/resource/resmgr/PDFs/AlExtAidsAutoLtwtng_DN115289.pdf, Accessed 23 Sept 2020.

2.Y. Abe, T. Kato and K. Mori: J. Mater. Process. Technol., 2009, vol. 209, pp. 3914-3922.

3.S. Kaya: Int. J. Adv. Manuf. Technol., 2014, vol. 77, pp. 807-817.

4.J. Yu, G. Zhao and L. Chen: J. Mater. Process. Technol., 2016, vol. 230, pp. 153-166.

5.Y.A. Khan, H.S. Valberg and B.O.T. Jacobsen: Int. J. Mater. Form., 2010, vol. 3, pp. 379-382.

6.F. Gagliardi, M. Schwane, T. Citrea, M. Haase, N.B. Khalifa and A.E. Tekkaya: Key Eng. Mater., 2014, vol. 622-623, pp. 87-94.

7.F. Gagliardi, I. Alfaro, G. Ambrogio, L. Filice and E. Cueto: J. Mech. Sci. Technol., 2013, vol. 27, pp. 1089-1095.

8.F. Gagliardi, G. Ambrogio and L. Filice: Cirp Ann-Manuf. Technol., 2012, vol. 61, pp. 231-234.

9.D. Tang, W. Fang, X. Fan, T. Zou, Z. Li, H. Wang, D. Li, Y. Peng and P. Wu: Materials, 2018, vol. 12, p. 16.

J. Yu, G. Zhao, C. Zhang and L. Chen: Mater. Sci. Eng. A, 2017, vol. 682, pp. 679-690.

11.G.J. Chen, L. Chen, G.Q. Zhao, C.S. Zhang and W.C. Cui: J. Alloys Compd., 2017, vol. 710, pp. 80-91.

K. Zhang, K. Marthinsen, B. Holmedal, T. Aukrust and A. Segatori: Mater. Sci. Eng. A, 2018, vol. 722, pp. 20-29.

13.L. Chen, G. Chen, J. Tang, G. Zhao and C. Zhang: Mater. Charact., 2019, vol. 158, p. 109953.

14.D. Tang, X.H. Fan, W.L. Fang, D.Y. Li, Y.H. Peng and H.M. Wang: Mater. Charact., 2018, vol. 142, pp. 449-457.

15.X. Xu, G. Zhao, Y. Wang, X. Chen and C. Zhang: Vacuum, 2019, vol. 167, pp. 28-39.

C.L. Liu, X. Wang, N.C. Parson, and W.J. Poole: Mater. Sci. Eng. A, 2020, p. 140605.

17.W. Fang, D. Tang, H. Wang, D. Li and Y. Peng: J. Mater. Process. Technol., 2020, vol. 277, p. 116418.

C. Zhang, G. Zhao, Z. Chen, H. Chen and F. Kou: Mater. Sci. Eng. B, 2012, vol. 177, pp. 1691-1697.

19.M. Schikorra, L. Donati, L. Tomesani and A.E. Tekkaya: J. Mater. Process. Technol., 2008, vol. 201, pp. 156-162.

20.C.S. Zhang, G.Q. Zhao, Y.J. Guan, A.J. Gao, L.J. Wang and P. Li: Int. J. Adv. Manuf. Technol., 2015, vol. 78, pp. 927-937.

21.M. Schikorra, L. Donati, L. Tomesani and A.E. Tekkaya: J. Mech. Sci. Technol., 2007, vol. 21, pp. 1445-1451.

C. Jowett, Y. Mahmoodkhani, N.C. Parson, and G. Garza: Proceedings of Eleventh International Aluminum Extrusion Technology Seminar and Exposition, 2016, Chicago

23.X. Duan and T. Sheppard: Metall. Mater. Trans. A, 2003, vol. 351, pp. 282-292.

24.C.M. Sellars and W.J. McTegart: Acta Metall., 1966, vol. 14, pp. 1136-1138.

X. Qian, N. Parson and X.G. Chen: Mater. Sci. Eng. A, 2019, vol. 764, p. 138253.

26.C. Sellars and W.M. Tegart: Int. Metall. Rev., 1972, vol. 17, pp. 1-24.

27.T. Sheppard and D. Wright: Met. Technol., 1979, vol. 6, pp. 215-223.

28.S.M. Lou, Y.X. Wang, C.X. Liu, S. Lu, S.J. Liu and C.J. Su: J. Mater. Eng. Perform., 2017, vol. 26, pp. 4121-4130.

29.C. Zhang, M. Wen, G. Zhao, L. Chen, W. Sun and K. Bai: Thin Wall Struct., 2019, vol. 135, pp. 65-77.

30.T. Sheppard and A. Jackson: Mater. Sci. Technol., 1997, vol. 13, pp. 203-209.

31.Y. Liu, C. Geng, Q. Lin, Y. Xiao, J. Xu and W. Kang: J. Alloys Compd., 2017, vol. 713, pp. 212-221.

32.Y. Mahmoodkhani, J. Chen, M.A. Wells, W.J. Poole and N.C. Parson: Metall. Mater. Trans. A, 2019, vol. 50, pp. 5324-5335.

33.Y. Mahmoodkhani, M.A. Wells, N. Parson and W.J. Poole: J. Mater. Process. Technol., 2014, vol. 214, pp. 688-700.

34.N. Nanninga, C. White, O. Mills and J. Lukowski: Int. J. Fatigue, 2010, vol. 32, pp. 238-246.

35.A.J. den Bakker, X. Wu, L. Katgerman and S. van der Zwaag: Mater. Sci. Technol., 2015, vol. 31, pp. 94-104.

36.X.H. Fan, D. Tang, W.L. Fang, D.Y. Li and Y.H. Peng: Mater. Charact., 2016, vol. 118, pp. 468-480.

Z.J. Wang, L. Zhai, M. Ma, H. Yuan and W.C. Liu: Mater. Sci. Eng. A, 2015, vol. 644, pp. 194-203.

38.G. Liu, J. Zhou and J. Duszczyk: J. Mater. Process. Technol., 2008, vol. 200, pp. 185-198.

Acknowledgments

This work was undertaken, in part, thanks to funding from the Canada Research Chair program (Poole). Additional support was provided by Rio Tinto Aluminum, the Ford Motor Company, and NSERC Canada.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 18, 2020; accepted April 30, 2021.

Rights and permissions

About this article

Cite this article

Wang, Y., Zang, A., Mahmoodkhani, Y. et al. The Effect of Bridge Geometry on Microstructure and Texture Evolution During Porthole Die Extrusion of an Al–Mg–Si–Mn–Cr Alloy. Metall Mater Trans A 52, 3503–3516 (2021). https://doi.org/10.1007/s11661-021-06322-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06322-5