Abstract

Additive manufacturing (AM) processes have widely varying thermal environments, which dictate the solidification of alloys during solidification. Here, we use binder jet 3D printing (BJ3DP), electron beam freeform fabrication (EBF3), and direct metal laser sintering (DMLS) to fabricate samples of Inconel 625, displaying the significant differences in microstructure brought about purely by the thermal gradients produced in each manufacturing method. Dislocation density and elastic strain are measured using high-resolution electron backscatter diffraction and the spatial relationship between these features is analyzed with respect to the relative thermal environments of each AM technique, with DMLS exhibiting microstructure typical of high thermal gradients and rapid solidification. Increasing thermal gradient and solidification rate results in a stronger spatial dependence of microscale elastic strain on GND density. Our results also demonstrate the use of statistical techniques to quantify microstructural features in relation to processing, which has potential for informing frameworks which can predict microstructure and material properties of AM components.

Similar content being viewed by others

References

T. Debroy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang: Prog. Mater. Sci. 92, 112–124 (2018). https://doi.org/10.1016/j.pmatsci.2017.10.001.

R. Liu, Z. Wang, T. Sparks, F. Liou, and J. Newkirk: in Laser Additive Manufacturing: Materials, Design, Technologies, and Applications, Elsevier Inc., Amsterdam, 2017, pp. 351–71.

P.D. Enrique, E. Marzbanrad, Y. Mahmoodkhani, Z. Jiao, E. Toyserkani, and N.Y. Zhou: Surf. Coatings Technol., 2019, vol. 362, pp. 141–9.

L.E. Murr, S.M. Gaytan, D.A. Ramirez, E. Martinez, J. Hernandez, K.N. Amato, P.W. Shindo, F.R. Medina, and R.B. Wicker: J. Mater. Sci. Technol., 2012, vol. 28, 1–14.

Y.-L. Hao, S.-J. Li, and R. Yang: Rare Met., 2016, vol. 35, pp. 661–71.

J.J. Lewandowski and M. Seifi: Annu. Rev. Mater. Res., 2016, vol. 46, pp. 151–86.

A. Mostafaei, E.L. Stevens, E.T. Hughes, S.D. Biery, C. Hilla, and M. Chmielus: Mater. Des., 2016, vol. 108, pp. 126–35.

A. Mostafaei, J. Toman, E.L. Stevens, E.T. Hughes, Y.L. Krimer, and M. Chmielus: Acta Mater., 2017, vol. 124, pp. 280–9.

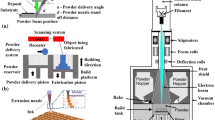

K. Taminger and R. Hafley: Proc. 3rd Annu. Automot. Compos. Conf., 2003, pp. 9–10.

Y. Tian, D. McAllister, H. Colijn, M. Mills, D. Farson, M. Nordin, and S. Babu: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2014, vol. 45A, pp. 4470–83.

X. Zhao, J. Chen, X. Lin, and W. Huang: Mater. Sci. Eng. A, 2008, vol. 478, pp. 119–24.

T.M. Rodgers, J.D. Madison, and V. Tikare: Comput. Mater. Sci., 2017, vol. 135, pp. 78–89.

L.M. Suave, J. Cormier, P. Villechaise, A. Soula, Z. Hervier, D. Bertheau, and J. Laigo: Metall. Mater. Trans. A, 2014, vol. 45, pp. 2963–82.

M.R. Stoudt, E.A. Lass, D.S. Ng, M.E. Williams, F. Zhang, C.E. Campbell, G. Lindwall, and L.E. Levine: Metall. Mater. Trans. A, 2018, vol. 49, pp. 3028–37.

E. Popova, T.M. Rodgers, X. Gong, A. Cecen, J.D. Madison, and S.R. Kalidindi: Integr. Mater. Manuf. Innov., 2017, vol. 6, pp. 54–68.

B. Yuan, G.M. Guss, A.C. Wilson, S.P. Hau‐Riege, P.J. DePond, S. McMains, M.J. Matthews, and B. Giera: Adv. Mater. Technol., 2018, vol. 3, p. 1800136.

P. Nandwana, A.M. Elliott, D. Siddel, A. Merriman, W.H. Peter, and S.S. Babu: Curr. Opin. Solid State Mater. Sci., 2017, 21(4):207–218.

K. Kimes, K. Myers, A. Klein, M. Ahlfors, E. Stevens, and M. Chmielus: Microsc. Microanal., 2019, vol. 25, pp. 2600–1.

R. Hafley, K.M.B. Taminger, and R. Bird: AIAA Papers, 2007, pp. 1–9.

S.C. Joshi and A.A. Sheikh: Virtual Phys. Prototyp., 2015, vol. 10, pp. 111–75.

X. Shu, G. Chen, J. Liu, B. Zhang, and J. Feng: Mater. Lett., 2018, vol. 213, pp. 374–7.

J. Xu, J. Zhu, J. Fan, Q. Zhou, Y. Peng, and S. Guo: Vacuum, 2019, vol. 167, pp. 364–73.

K.M. Taminger and R.A. Hafley: NATO/RTOAVT.

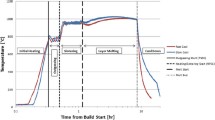

J. Gockel, J. Beuth, and K. Taminger: Addit. Manuf., 2014, vol. 1, pp. 119–26.

L.M. Sochalski-Kolbus, E.A. Payzant, P.A. Cornwell, T.R. Watkins, S.S. Babu, R.R. Dehoff, M. Lorenz, O. Ovchinnikova, and C. Duty: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2015, vol. 46, pp. 1419–32.

A.K. Agrawal, G. Meric de Bellefon, and D. Thoma: Mater. Sci. Eng. A., 2020, vol. 793, 139841. https://doi.org/10.1016/j.msea.2020.139841.

A.E. Patterson, S.L. Messimer, and P.A. Farrington: Technologies, 2017, vol. 5, p. 15.

G. Nicoletto, R. Konečná, M. Frkáň, and E. Riva: Int. J. Fatigue, 2018, vol. 116, pp. 140–8.

D.W. Brown, J.D. Bernardin, J.S. Carpenter, B. Clausen, D. Spernjak, and J.M. Thompson: Mater. Sci. Eng. A, 2016, vol. 678, pp. 291–8.

Z. Wang, E. Denlinger, P. Michaleris, A.D. Stoica, D. Ma, and A.M. Beese: Mater. Des., 2017, vol. 113, pp. 169–77.

P.J. Withers, H.K.D.H. Bhadeshia, P.J. Withers, and H.K.D.H. Bhadeshia: Mater. Sci. Technol., 2001, vol. 17(4), pp. 355–65. https://doi.org/10.1179/026708301101509980.

T.B. Britton and A.J. Wilkinson: Ultramicroscopy, 2011, vol. 111, pp. 1395–404.

A.J. Wilkinson, G. Meaden, and D.J. Dingley: Ultramicroscopy, 2006, vol. 106, pp. 307–13.

K.A. Small, Z. Clayburn, R. DeMott, S. Primig, D. Fullwood, and M.L. Taheri: Mater. Sci. Eng. A, 2020, vol. 785, p. 139380.

K.M. Bertsch, G. Meric de Bellefon, B. Kuehl, and D.J. Thoma: Acta Mater., 2020, vol. 199, pp. 19–33.

Y. Zhong, L. Liu, S. Wikman, D. Cui, and Z. Shen: J. Nucl. Mater., 2016, vol. 470, pp. 170–8.

M.D. Sangid, T.A. Book, D. Naragani, J. Rotella, P. Ravi, A. Finch, P. Kenesei, J.-S. Park, H. Sharma, J. Almer, and X. Xiao: Addit. Manuf., 2018, vol. 22, pp. 479–96.

Y.S.J. Yoo, T.A. Book, M.D. Sangid, and J. Kacher: Mater. Sci. Eng. A, 2018, vol. 724, pp. 444–51.

A. Hadadzadeh, B. Shalchi Amirkhiz, A. Odeshi, J. Li, and M. Mohammadi: Addit. Manuf., 2019, vol. 28, pp. 1–13.

T. Pinomaa, M. Lindroos, M. Walbrühl, N. Provatas, and A. Laukkanen: Acta Mater., 2020, vol. 184, pp. 1–16.

G. Meric de Bellefon, K.M. Bertsch, M.R. Chancey, Y.Q. Wang, and D.J. Thoma: J. Nucl. Mater., 2019, vol. 523, pp. 291–8.

L.E. Murr: Addit. Manuf., 2015, vol. 5, pp. 40–53.

Y. Han, R.J. Griffiths, H.Z. Yu, and Y. Zhu: J. Mater. Res., 2020, vol. 35, pp. 1936–48.

S.S. Razvi, S. Feng, A. Narayanan, Y.T.T. Lee, and P. Witherell: in Proceedings of the ASME Design Engineering Technical Conference, vol. 1, 2019.

C. Herriott and A.D. Spear: Comput. Mater. Sci., 2020, vol. 175, p. 109599.

H. Chandler, ed.: Heat Treater’s Guide: Practices and Procedures for Nonferrous Alloys, ASM International, Materials Park, OH, 1996.

E.A. Lass, M.R. Stoudt, M.E. Williams, M.B. Katz, L.E. Levine, T.Q. Phan, T.H. Gnaeupel-Herold, and D.S. Ng: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2017, vol. 48, pp. 5547–58.

S. Qin, T.C. Novak, M.K. Vailhe, Z.-K. Liu, and A.M. Beese: Mater. Sci. Eng. A, 2021, vol. 806, p. 140808.

G. Marchese, S. Parizia, M. Rashidi, A. Saboori, D. Manfredi, D. Ugues, M. Lombardi, E. Hryha, and S. Biamino: Mater. Sci. Eng. A, 2020, vol. 769, p. 138500.

M. Godec, S. Zaefferer, B. Podgornik, M. Šinko, and E. Tchernychova: Mater. Charact., 2020, vol. 160, p. 110074.

C. Li, R. White, X.Y. Fang, M. Weaver, and Y.B. Guo: Mater. Sci. Eng. A, 2017, vol. 705, pp. 20–31.

S.K. Nayak, S.K. Mishra, A.N. Jinoop, C.P. Paul, and K.S. Bindra: J. Mater. Eng. Perform., 2020, vol. 29, pp. 7636–47.

BYU – OpenXY: https://github.com/BYU-MicrostructureOfMaterials/OpenXY.

T.B. Britton and A.J. Wilkinson: Ultramicroscopy, 2012, vol. 114, pp. 82–95.

A.C. Leff, C.R. Weinberger, and M.L. Taheri: Ultramicroscopy, 2015, vol. 153, pp. 9–21.

A. Shivanandan, A. Radenovic, and I.F. Sbalzarini: BMC Bioinformatics, 2013, vol. 14, p. 349.

N.H. Paulson, M.W. Priddy, D.L. McDowell, and S.R. Kalidindi: Acta Mater., 2017, vol. 129, pp. 428–38.

C. Xu, S. Gao, and M. Li: Comput. Mater. Sci., 2017, vol. 130, pp. 39–49.

A. Gupta, A. Cecen, S. Goyal, A.K. Singh, and S.R. Kalidindi: Acta Mater., 2015, vol. 91, pp. 239–54.

J. Ling, M. Hutchinson, E. Antono, B. DeCost, E.A. Holm, and B. Meredig: Mater. Discov., 2017, vol. 10, pp. 19–28.

S. Keshavarz and S. Ghosh: Int. J. Solids Struct., 2015, vol. 55, pp. 17–31.

G. Fleury, F. Schubert, and H. Nickel: Comput. Mater. Sci., 1996, vol. 7, pp. 187–93.

H. Mughrabi: Acta Metall., 1983, vol. 31, pp. 1367–79.

C. Herriott, X. Li, N. Kouraytem, V. Tari, W. Tan, B. Anglin, A.D. Rollett, and A.D. Spear: Model. Simul. Mater. Sci. Eng., 2019, vol. 27, p. 025009.

A. Mostafaei, P. Rodriguez De Vecchis, I. Nettleship, and M. Chmielus: Mater. Des., 2019, vol. 162, pp. 375–83.

A. Lal, R.G. Iacocca, and R.M. German: J. Mater. Sci., 2000, vol. 35, pp. 4507–18.

R.M. German: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 1997, vol. 28, pp. 1553–67.

H.L. Wei, G.L. Knapp, T. Mukherjee, and T. Debroy: Addit. Manuf., 2018, vol. 25, pp. 448–59.

A. Panin, M. Kazachenok, O. Perevalova, S. Martynov, A. Panina, and E. Sklyarova: Metals (Basel), 2019, vol. 9(6), p. 699. https://doi.org/10.3390/met9060699.

J.N. Zalameda, E.R. Burke, R.A. Hafley, K.M. Taminger, C.S. Domack, A. Brewer, and R.E. Martin: Thermosense Therm. Infrared Appl. XXXV, 2013, vol. 8705, p. 87050M.

L.E. Criales and T. Özel: Prog. Addit. Manuf., 2017, vol. 2, pp. 169–77.

N. Li, S. Huang, G. Zhang, R. Qin, W. Liu, H. Xiong, G. Shi, and J. Blackburn: J. Mater. Sci. Technol., 2019, vol. 35, pp. 242–69.

M. Chmielus, E. Stevens, A. Mostafaei, P. Rodriguez De Vecchis, R. Rodriguez De Vecchis, A. Acierno, K. Kimes, and J. Toman: in The 6th International Conference on Ferromagnetic Shape Memory Alloys, 2019, pp. 46–47.

F. Pyczak, B. Devrient, and H. Mughrabi: Superalloys, 2004, pp. 827–36.

K.M. Taminger and R.A. Hafley: Electron Beam Freeform Fabrication for Cost Effective Near-Net Shape Manufacturing, in NATO/RTOAVT-139 Specialists’ Meeting on Cost Effective Manufacture via Net Shape Processing, Amsterdam, The Netherlands, NATO.

R.K. Bird and J. Hibberd: Tensile properties and microstructure of Inconel 718 fabricated with electron beam freeform fabrication, in NASA Technical Memorandum TM-2009-215929, 2009.

M. Huo, L. Liu, W. Yang, Y. Li, S. Hu, H. Su, J. Zhang, and H. Fu: J. Mater. Res., 2019, vol. 34, pp. 251–60.

R. Willnecker, D.M. Herlach, and B. Feuerbacher: Phys. Rev. Lett., 1989, vol. 62, pp. 2707–10.

N. Raghavan, R. Dehoff, S. Pannala, S. Simunovic, M. Kirka, J. Turner, N. Carlson, and S.S. Babu: Acta Mater., 2016, vol. 112, pp. 303–14.

V. Thampy, A.Y. Fong, N.P. Calta, J. Wang, A.A. Martin, P.J. Depond, A.M. Kiss, G. Guss, Q. Xing, R.T. Ott, A. van Buuren, M.F. Toney, J.N. Weker, M.J. Kramer, M.J. Matthews, C.J. Tassone, and K.H. Stone: Sci. Rep., 2020, vol. 10, p. 1981.

K.N. Amato, S.M. Gaytan, L.E. Murr, E. Martinez, P.W. Shindo, J. Hernandez, S. Collins, and F. Medina: Acta Mater., 2012, vol. 60, pp. 2229–39.

E. Chlebus, K. Gruber, B. Kuznicka, J. Kurzac, and T. Kurzynowski: Mater. Sci. Eng. A, 2015, vol. 639, pp. 647–55.

P.J. Withers and H.K.D.H. Bhadeshia: Mater. Sci. Technol., 2001, vol. 17, pp. 366–75.

A.T. Polonsky, N. Raghavan, M.P. Echlin, W.C. Lenthe, M.M. Kirka, R.R. Dehoff, and T.M. Pollock: Microsc. Microanal, 2019, vol. 25, p. 2019.

Q. Wu, T. Mukherjee, C. Liu, J. Lu, and T. Debroy: Addit. Manuf., 2019, vol. 29, 100808. https://doi.org/10.1016/j.addma.2019.100808.

R. Jiang, A. Mostafaei, Z. Wu, A. Choi, P.-W. Guan, M. Chmielus, and A.D. Rollett: Addit. Manuf., 2020, vol. 35, p. 101282.

Acknowledgments

The authors would like to acknowledge the team at Hoeganaes Corp. in Cinnaminson, N.J., particularly Alex Zwiren and George Bernhard, for fabrication of the BJ3DP sample, Jacob Hochhalter at NASA Langley Research Center in Hampton, VA, for fabrication of the EBF3 sample, and Matthew Clemente and Elias Jelis at Army ARDEC at Picatinny Arsenal, N.J., for DMLS manufacturing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 30, 2020; accepted March 26, 2021.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Small, K.A., Taheri, M.L. Role of Processing in Microstructural Evolution in Inconel 625: A Comparison of Three Additive Manufacturing Techniques. Metall Mater Trans A 52, 2811–2820 (2021). https://doi.org/10.1007/s11661-021-06273-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06273-x