Abstract

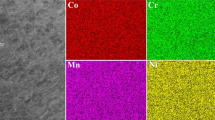

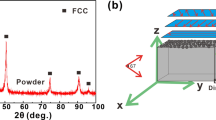

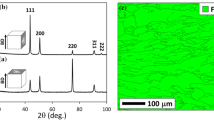

Additive manufacturing of an equimolar CoCrNi medium entropy alloy (MEA) by selective laser melting (SLM) was investigated, emphasizing its microstructure, properties, and metallurgical defects. It was found that SLM sample density exhibited a non-monotonic relation with their volume energy density (VED); the density first increased but then decreased while the input VED was gradually increasing. A maximal relative density of 98.9 pct was accessible at a VED of 83.3 J/mm3. X-ray diffraction indicated that the printed CoCrNi MEA exhibited an FCC single-crystal structure where the lattice constant decreased with the increasing VED owing to the evaporation of the Cr element in the SLM process. The average grain size gradually increased with increasing VED, irrespective of whether viewed from the top or the side of the printed part. Similarly, the residual stress increased with increasing VED, which produced more microcracks and deteriorated the tensile preformation of the printed samples, although the yield strength (630 MPa) showed no apparent difference at different VEDs. Owing to the ultrafine cell structure, the mechanical property of the SLM printed sample was twice that of cast or wrought CoCrNi MEA.

Similar content being viewed by others

References

[1] Y.F. Ye, Q. Wang, J. Lu, C.T. Liu and Y. Yang: Mater Today, 2016, vol. 19, pp. 349-62.

[2] Z. Li, F. Kormann, B. Grabowski, J. Neugebauer and D. Raabe: Acta Mater., 2017, vol. 136, pp. 262-70.

[3] Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw and Z.P. Lu: Prog. Mater. Sci., 2014, vol. 61, pp. 1-93.

[4] C.P. Lee, C.C. Chang, Y.Y. Chen, J.W. Yeh and H.C. Shih: Corros. Sci., 2008, vol. 50, pp. 2053-60.

[5] G. Laplanche, A. Kostka, C. Reinhart, J. Hunfeld, G. Eggeler and E.P. George: Acta Mater., 2017, vol. 128, pp. 292-303.

[6] S. Yoshida, T. Bhattacharjee, Y. Bai and N. Tsuji: Scripta Mater., 2017, vol. 134, pp. 33-36.

[7] Y.L. Zhao, T. Yang, Y. Tong, J. Wang, J.H. Luan, Z.B. Jiao, D. Chen, Y. Yang, A. Hu, C.T. Liu and J.J. Kai: Acta Mater., 2017, vol. 138, pp. 72-82.

[8] J. Miao, C.E. Slone, T.M. Smith, C. Niu, H. Bei, M. Ghazisaeidi, G.M. Pharr and M.J. Mills: Acta Mater., 2017, vol. 132, pp. 35-48.

[9] M.J. Jang, S. Praveen, H.J. Sung, J.W. Bae, J. Moon and H.S. Kim: J. Alloy. Compd, 2018, vol. 730, pp. 242-48.

[10] T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De and W. Zhang: Prog. Mater. Sci., 2018, vol. 92, pp. 112-224.

[11] Y.J Zhang, B. Song, X. Zhang and Y.S. Shi: Nano. Mater. Sci., 2019, vol. 1, pp. 208-214.

[12] H. Rao, S. Giet, K. Yang, X. Wu and C.H.J. Davies: Mater. Design, 2016, vol. 109, pp. 334-46.

[13] Y. Li, K. Zhou, P. Tan, S.B. Tor, C.K. Chua and K.F. Leong: Int. J. Mech. Sci., 2018, vol. 136, pp. 24-35.

[14] X.P. Li, X.J. Wang, M. Saunders, A. Suvorova, L.C. Zhang, Y.J. Liu, M.H. Fang, Z.H. Huang and T.B. Sercombe: Acta Mater., 2015, vol. 95, pp. 74-82.

[15] R. Li, M. Wang, T. Yuan, B. Song, C. Chen, K. Zhou and P. Cao: Powder Technol., 2017, vol. 319, pp. 117-28.

[16] L.B. Li, R.D. Li, T.C. Yuan, C. Chen, Z.J. Zhang and X.F. Li: Mat. Sci. Eng. A.-Struct., 2020, vol. 787, pp. 139492.

[17] B. Song, Z. Wang, Q. Yan, Y. Zhang, J. Zhang, C. Cai, Q. Wei and Y. Shi: Mat. Sci. Eng. A.-Struct., 2017, vol. 707, pp. 478-87.

[18] R. Li, Y. Shi, Z. Wang, L. Wang, J. Liu and W. Jiang: Appl. Surf. Sci., 2010, vol. 256, pp. 4350-56.

[19] H. Azizi, H. Zurob, B. Bose, S.R. Ghiaasiaan, X. Wang, S. Coulson, V. Duz and A.B. Phillion: Addit. Manuf, 2018, vol. 21, pp. 529-35.

[20] E. Tiferet, O. Rivin, M. Ganor, H. Ettedgui, O. Ozeri, E.N. Caspi and O. Yeheskel: Addit. Manuf, 2016, vol. 10, pp. 43-46.

[21] Y. Zhang, J. Zhang, Q. Yan, L. Zhang, M. Wang, B. Song and Y. Shi: Scripta Mater., 2018, vol. 148, pp. 20-23.

[22] D. Ouyang, W. Xing, N. Li, Y. Li and L. Liu: Addit. Manuf, 2018, vol. 23, pp. 246-52.

[23] Y. Brif, M. Thomas and I. Todd: Scripta Mater., 2015, vol. 99, pp. 93-96.

[24] J. Joseph, N. Stanford, P. Hodgson and D.M. Fabijanic: Scripta Mater., 2017, vol. 129, pp. 30-34.

[25] J. Joseph, P. Hodgson, T. Jarvis, X. Wu, N. Stanford and D.M. Fabijanic: Materials Science and Engineering: A, 2018, vol. 733, pp. 59-70.

[26] R. Li, P. Niu, T. Yuan, P. Cao, C. Chen and K. Zhou: J. Alloy. Compd, 2018, vol. 746, pp. 125-34.

[27] Z. Xu, H. Zhang, W. Li, A. Mao, L. Wang, G. Song and Y. He: Addit. Manuf, 2019, vol. 28, pp. 766-71.

[28] J. Guo, M. Goh, Z. Zhu, X. Lee, M.L.S. Nai and J. Wei: Mater. Design, 2018, vol. 153, pp. 211-20.

[29] Z. Tong, X. Ren, J. Jiao, W. Zhou, Y. Ren, Y. Ye, E.A. Larson and J. Gu: J. Alloy. Compd, 2019, vol. 785, pp. 1144-59.

[30] P.D. Niu, R.D. Li, T.C. Yuan, S.Y. Zhu, C. Chen, M.B. Wang and L. Huang: Intermetallics, 2019, vol. 104, pp. 24-32.

[31] S. Luo, P. Gao, H. Yu, J. Yang, Z. Wang and X. Zeng: J. Alloy. Compd, 2019, vol. 771, pp. 387-97.

[32] M. Zhang, X. Zhou, D. Wang, W. Zhu, J. Li and Y.F. Zhao: Mat. Sci. Eng. A.-Struct., 2019, vol. 743, pp. 773-84.

[33] T. Fujieda, M. Chen, H. Shiratori, K. Kuwabara, K. Yamanaka, Y. Koizumi, A. Chiba and S. Watanabe: Addit. Manuf, 2019, vol. 25, pp. 412-20.

[34] D. Gu, Y. Hagedorn, W. Meiners, G. Meng, R.J.S. Batista, K. Wissenbach and R. Poprawe: Acta Mater., 2012, vol. 60, pp. 3849-60.

[35] K.G. Prashanth, S. Scudino, T. Maity, J. Das and J. Eckert: Mater Res Lett, 2017, vol. 5, pp. 386-90.

[36] M.J. Matthews, G. Guss, S.A. Khairallah, A.M. Rubenchik, P.J. Depond and W.E. King: Acta Mater., 2016, vol. 114, pp. 33-42.

[37] R. Hu, S. Pang, X. Chen, L. Liang and X. Shao: Int. J. Heat Mass Tran., 2017, vol. 115, pp. 258-63.

[38] Z.G. Zhu, Q.B. Nguyen, F.L. Ng, X.H. An, X.Z. Liao, P.K. Liaw, S.M.L. Nai and J. Wei: Scripta Mater., 2018, vol. 154, pp. 20-24.

[39] P. Nie, O.A. Ojo and Z. Li: Acta Mater., 2014, vol. 77, pp. 85-95.

[40] S.S. Al-Bermani, M.L. Blackmore, W. Zhang and I. Todd: Metall. Mater. Trans. A., 2010, vol. 41A, pp. 3422-34.

[41] J. Wang, H. Yang, H. Huang, J. Ruan and S. Ji: Mater. Lett., 2019, vol. 254, pp. 77-80.

[42] R. Chang, W. Fang, X. Bai, C. Xia, X. Zhang, H. Yu, B. Liu and F. Yin: J. Alloy. Compd, 2019, vol. 790, pp. 732-43.

[44] M. Gaumann, C. Bezencon, P. Canalis and W. Kurz: Acta Mater., 2001, vol. 49, pp. 1051-62.

[45] S. Tammas-Williams, H. Zhao, F. Leonard, F. Derguti, I. Todd and P.B. Prangnell: Mater. Charact., 2015, vol. 102, pp. 47-61.

[46] S. Praveen, J.W. Bae, P. Asghari-Rad, J.M. Park and H.S. Kim: Mat. Sci. Eng. A.-Struct., 2018, vol. 735, pp. 394-97.

[48] M.P. Agustianingrum, S. Yoshida, N. Tsuji and N. Park: J. Alloy. Compd, 2019, vol. 781, pp. 866-72.

[49] J. Wang, H. Yang, H. Huang, J. Ruan and S. Ji: J. Alloy. Compd, 2019, vol. 798, pp. 576-86.

[50] Z. Wu, H. Bei, G.M. Pharr and E.P. George: Acta Mater. 2014, vol. 81, pp. 428-441.

S. Guan, D. Wan, K. Solberg, F. Berto, T. Welo, T.M. Yue and K.C. Chan: Mat. Sci. Eng. A, 2019, vol. 761, pp.

[54] M. Zaiser and E.C. Aifantis: Scripta Mater., 2003, vol. 48, pp. 133-39.

Acknowledgments

The authors acknowledge the National Natural Science Foundation of China (No. 51871249), financial support of the National Key R&D Program of China (No. 2016YFB1100101), Science and Technology Planning Project of Changsha (No. kq1801068), Huxiang Young Talents (No. 2018RS3007), Science Project of Shenzhen (No. JCYJ20180508151903646), and Science Project of Guangxi (No. GuikeAB19050002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 15, 2020; accepted December 3, 2020.

Rights and permissions

About this article

Cite this article

Niu, P., Li, R., Gan, K. et al. Microstructure, Properties, and Metallurgical Defects of an Equimolar CoCrNi Medium Entropy Alloy Additively Manufactured by Selective Laser Melting. Metall Mater Trans A 52, 753–766 (2021). https://doi.org/10.1007/s11661-020-06121-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06121-4