Abstract

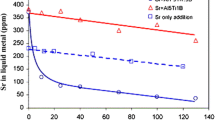

Al-5Ti-1B is the most widely used grain refiner for Al alloys. However, it is not effective for grain refining Al alloys containing more than 3 wt pct Si. This adverse effect of Si is referred to as Si poisoning. In spite of extensive experimental and theoretical investigations in the past decades, the exact mechanism for Si poisoning is still not clear. In this work, the state-of-the-art electron microscopy was performed to investigate the mechanism for Si poisoning. Our experimental results suggest that Si segregates preferably to the TiB2/Al-Si melt interface and the pre-existing Al3Ti 2-dimensional compound (2DC) layer on TiB2 surface dissolves into the Al-Si melt. Based on the experimental results, we have postulated a new mechanism for Si poisoning: interfacial segregation of Si leads to enrichment of Si at the TiB2/Al-Si melt interface, and this in turn makes the pre-existing Al3Ti 2DC on the TiB2 surface unstable and dissolve gradually in the melt, resulting in a loss of TiB2 nucleation potency and hence a decreased total number of potent TiB2 particles available for heterogeneous nucleation and grain initiation and consequently an increased grain size. This mechanism for Si poisoning can explain consistently the experimentally observed phenomenon reported in the literature.

Similar content being viewed by others

References

A. Cibula: J. Inst. Met., 1951–1952, vol. 80, pp 1–16.

D.G. McCartney, Int. Mater. Rev., 1989, vol. 34, pp. 247-260.

M. Easton and D. StJohn, Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1613-1623.

B.S. Murty, S.A. Kori and M. Chakraborty, 2002, Int. Mater. Rev., vol. 47, pp. 3-47.

T.E. Quested, Mater. Sci. Tech., 2004, vol. 20, pp. 1357-1369.

L. Greer: J. Chem. Phys., 2016, vol. 145, pp. 211704.1–211704.14.

M.A. Easton, M. Qian, A. Prasad, and D.H. StJohn, Curr. Opin. Solid State Mater. Sci., 2016, vol. 20, pp. 13-24.

Z. Fan, Y. Wang, Y. Zhang, T. Qin, X.R. Zhou, G.E. Thompson, T. Pennycook and T. Hashimoto, Acta Mater., 2015, vol. 84, pp. 292-304.

G.P. Jones and J. Pearson, Metall. Trans. B, 1976, vol. 7B, pp. 223-234.

A.A. Abdel-Hamid, Z. Metallkd., 1989, vol. 80, pp. 643-647.

M. Johnsson, Z. Metallkd. 1994, vol. 85, pp. 786-789.

J.A. Spittle and S. Sadli, Cast Metals, 1995, vol. 8, pp. 247-253.

A. ArjunaRao, B.S. Murty and M. Chakraborty, Mater. Sci. Technol., 1997, vol. 13, pp. 769-777.

M.A. Kearns, P. Cooper, Mater. Sci. Technol., 1997, vol. 13, pp. 650-654.

M.E.J. Birch, in: C. Baker, P.J. Gregson, S.J. Harris and C.J. Peers (eds.), Aluminium-lithium Alloys III, The Institute of Metals, London, 1986, pp. 152-158.

C.R. Chakravorty and M. Chakraborty, Cast Metals, 1991, vol. 4, pp. 98-100.

A. ArjunaRao, B.S. Murty and M. Chakraborty, Metall. Mater. Trans. A, vol. 27A, pp. 791-800 (1983)

A. ArjunaRao, B.S. Murty and M. Chakraborty, Int. J. Cast Met. Res., 1996, vol. 9, pp. 125-132.

J. A. Spittle, Inter. J Cast Metals Res., 2006, vol. 19, pp. 210-222.

G.K. Sigworth and M.M. Guzowaski, AFS Trans., 1985, vol. 93, pp. 907-912.

M. Johnsson, Z. Metallk., 1994, vol. 85, pp. 781-785.

M. Johnsson and L. Backerud, Z. Metallk., 1996, vol. 87, pp. 216-220.

P. Hoefs, W. Reif and W. Schneider, Giesserei, 1994, vol. 81, pp. 398-406.

M. Abdel-Reihim, N. Hess, W. Reif and M.E.J. Birch, J. Mater. Sci., vol. 22, pp. 213-218 (1987).

J.A. Spittle, J.M. Keeble, and M. Al Meshhedani: in Light Metals 1997, R. Huglen, ed., TMS, Warrendale PA, 1997, pp. 795–800.

J.E.C. Hutt, D.H. StJohn, L. Hogan and A.K. Dahle, Mater. Sci. Technol., 1999, vol. 15, pp. 495-500.

L. Backerud and M. Johnsson: in Light Metals 1996, W. Hale, ed., TMS, Anaheim CA, 1996, pp. 679–85.

M. Abdel-Reihim, N. Hess, W. Reif and M.E.J. Birch, J. Mater. Sci., 1987, vol. 22, pp. 213-218.

Y.C. Lee, A.K. Dahle, D.H. StJohn and J.E.C. Hutt, Mater. Sci. Eng. A, 1999, vol. 259, pp. 43-52.

Y. Birol, Inter. J. Cast Metals Res., 2013, vol. 26, pp. 22-27.

Y. Birol, Mater. Sci. Technol. 2012, vol. 28, pp. 385-389.

S.A. Kori, B.S. Murty and M. Chakraborty, Mater. Sci. Tech., 1999, vol. 15, pp. 986-992.

S.A. Kori, V. Auradi, B.S. Murty and M. Chakraborty, Mater. Forum, 2005, vol. 29, pp. 387-393.

A. Prasad, S.D. McDonald, H. Yasuda, K. Nogita and D.H. StJohn, J. Cryst. Growth, 2015, vol. 430, pp. 122-137.

D. Qiu, J.A. Taylor, M-X. Zhang and P.M. Kelly, Acta Mater. 2007, vol. 55, pp. 1447-1456.

Y. Wang, C.M. Fang, L. Zhou, T. Hashimoto, X. Zhou, Q.M. Ramasse and Z. Fan, Acta Mater., 2019, vol. 164, pp. 428-439.

P.S. Mohanty and J.E. Gruzleski, Acta Mater., 1996, vol. 44, pp. 3749-3760.

G.S.V. Kumar, B.S. Murty and M. Chakraborty, J. Alloys Compd., 2009, vol. 472, pp. 112-120.

T. Wang, H. Fu, Z. Chen, J. Xu, J. Zhu, F. Cao and T. Li, J. Alloys Compd., 2012, vol. 511, pp. 45-49.

Y. Birol, Mater. Sci. Technol., 2012, vol. 28, pp. 481-486.

S.A. Kori, B.S. Murty and B.S. Chakraborty, Mater. Sci. Eng. A, 2000, vol. 283, pp. 94-104.

L. Yu, X. Liu, Z. Wang and X. Bian, J. Mater. Sci., 2005, vol. 40, pp. 3865-3867.

H. Zhao, H. Bai, J. Wang and S. Guan, Mater. Charact., 2009, vol. 60, pp. 377-383.

P. Li, S. Liu, L. Zhang and X. Liu, Mater. Design, 2013, vol. 47, pp. 522-528.

Y. Birol, J. Alloys Compd. 2012, vol. 513, pp. 150-153.

Y. Birol, Mater. Sci. Tech., 2012, vol. 28, pp. 363-367.

Z. Chen, H. Kang, G. Fan, J. Li, Y. Lu, J. Jie, Y. Zhang, T. Li, X. Jian and T. Wang, Acta Mater., 2016, vol. 120, pp. 168-178.

M. Nowak, L. Bolzoni and N. HariBabu, Mater. Design, 2015, vol. 66, pp. 366-375.

L. Bolzoni, M. Nowak and N. HariBabu, Mater. Design, 2015, vol. 66, pp. 376-383.

L. Bolzoni and N. HariBabu, Metall. Mater. Trans. A, 2019, vol. 50A, pp. 746-756.

M.E.J. Birch, P. Fisher, in: T. Sheppard (ed.), Aluminium Technology 86, The Institute of Metals, London, 1986, pp. 117-124.

B.J. McKay: PhD Thesis, University of Oxford, Oxford, UK, 2001.

B.J. McKay, P. Cizek, P. Schumacher and K.A.Q. O’Reilly, Mater. Sci. Eng. A, 2001, vol. 304-306, pp. 240-244.

P. Schumacher and B. J. McKay, J. Non-Cryst. Solids, 2003, vol. 317, pp. 123-128.

T.E. Quested, A.T. Dinsdale and A.L. Greer, Mater. Sci. Tech., 2006, vol. 22, pp. 1126-1134.

P.S. Cooper, A. Hardman, D. Boot and E. Burhop, in: P. Crepeau (ed.), Light Metals 2003, TMS, Warrendale PA, 2003, pp. 923-928.

T.E. Quested, A.T. Dinsdale and A.L. Greer, Acta Mater., 2005, vol. 53, pp. 1323-1334.

M. Johnsson, Thermochim. Acta, 1995, vol. 256, pp. 107-121.

J.E.C. Hutt, A.K. Dahle, Y.C. Lee and D.H. StJohn, in: C.E. Eckert (ed.), Light Metals 1999, TMS, Warrendale PA, 1999, pp. 685-692.

W. Khalifa, F. H. Samuel and J. E. Gruzleski, Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3233-3250.

M.A. Easton, A. Prasad and D.H. StJohn, Mater. Sci. Forum, 2014, vol. 794-796, pp. 161-166.

Standard Test Procedure for Aluminum Alloy Grain Refiners (TP-1), The Aluminum Association, Washington, DC, 1990.

Z. Fan, Y. Wang, M. Xia and S. Arumuganathar, Acta Mater., 2009, vol. 57, pp. 4891-4901.

Y. Wang, Z. Fan, X. Zhou and G.E. Thompson, Phil. Mag. Lett., 2011, vol. 91, pp. 516-529.

A.L. Greer, A.M. Bunn, A. Tronche, P.V. Evans and D.J. Bristow, Acta Mater., 2000, vol. 48, pp. 2823-2835.

P. Schumacher and A.L. Greer, Mater. Sci. Eng. A, 1994, vol. A178, pp. 309-313.

P. Schumacher and A.L. Greer, Mater. Sci. Eng. A, 1994, vol. A181/A182, pp. 1335-1339.

H. Men and Z. Fan, Metall. Mater. Trans. A, 2018, vol. 49, pp. 2766-2777.

L. Wang and R.J. Arsenault, Metall. Trans. A, 1991, vol. 22A, pp. 3013-3018.

E. Hondros, M. Seah, S. Hofmann and P. Lejcek, in: R. Cahn, P. Haasen (eds.), Physical Metallurgy, North-Holland, Amsterdam, 1996, pp. 1201-1289.

J.W. Christian, The Theory of Transformations in Metals and Alloys, 3rd ed., Pergamon, Oxford, 2002.

B. Cantor, Philos. Trans. R. Soc. London. A, 2003, vol. 361, pp. 409-417.

Z. Fan, Metall. Mater. Trans. A, 2013, vol. 44A, pp. 1409-1418.

H. Men and Z. Fan, Metall. Mater. Trans. A, 2014, vol. 45A, pp. 5508-5516.

W.B. Pearson, A Handbook of Lattice Spacings and Structures of Metals and Alloys, Pergamon Press, London 1958, p. 382.

Acknowledgments

The EPSRC is gratefully acknowledged for providing financial support under grant number EP/N007638 /1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 24, 2020.

Rights and permissions

About this article

Cite this article

Wang, Y., Que, Z., Hashimoto, T. et al. Mechanism for Si Poisoning of Al-Ti-B Grain Refiners in Al Alloys. Metall Mater Trans A 51, 5743–5757 (2020). https://doi.org/10.1007/s11661-020-05950-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05950-7