Abstract

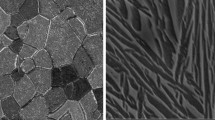

Ti-Nb-based low modulus metastable β-titanium alloys are popular choice for orthopedic implant materials. The performance of these materials could be affected by variation in crystallographic texture developed during processing. In the present study, texture evolution during unidirectional rolling and multi-step cross-rolling of the alloys Ti-34Nb-2Ta-3Zr-0.5O (TNTZO) and Ti-34Nb-2Ta-0.5O (TNTO) (in wt pct) has been studied. In both the alloys, the rolling texture is characterized by the absence of RD∥〈110〉 fiber, and cross-rolling leads to a stronger texture than unidirectional rolling. However, the prominent texture components in the cross-rolled condition are different for the two alloys. The TNTZO alloy shows the formation of a strong γ-fiber (ND∥〈111〉) along with {001}〈110〉 components while in TNTO, the texture is dominated by strong {001}〈110〉 component. These experimental results have been analyzed by simulations using viscoplastic self-consistent model and further validated by microstructural analysis using electron back scattered diffraction (EBSD). The deformation texture evolution has been attributed to a predominantly \( \left\{ {11\overline{2} } \right\}\left\langle {111} \right\rangle \) slip. The simulated texture of Ti-34Nb-2Ta-0.5O alloy shows a minor deviation from the experimental texture, which can be related to the reduced stability of this alloy due to the absence of Zr.

Similar content being viewed by others

References

M. Niinomi: J. Mech. Behav. Biomed., 2008, vol. 1, pp. 30-42.

E. Eisenbarth, D. Velten, M. Müller, R. Thull and J. Breme: Biomaterials, 2004, vol. 25, pp. 5705-5713.

J. Stráský, P. Harcuba, K. Václavová, K. Horváth, M. Landa, O. Srba and M. Janeček, J. Mech. Behav. Biomed, 2017, vol. 71, pp. 329-336.

H. Liu, M. Niinomi, M. Nakai, S. Obara and H. Fujii: Mater. Sci. Eng. A, 2017, vol. 704, pp. 10-17.

S. Acharya, S. Bahl, S.S. Dabas, S. Hassan, V. Gopal, A.G. Panicker, G. Manivasagam, S. Suwas and K. Chatterjee: Mater. Sci. Eng. C, 2019, vol. 103, pp. 109755.

T. Inamura, Y. Kinoshita, J. Kim, H. Kim, H. Hosoda, K. Wakashima, S. Miyazaki: Mater. Sci. Eng. A, 2006, vol. 438, pp. 865-869.

H. Kim, T. Sasaki, K. Okutsu, J. Kim, T. Inamura, H. Hosoda, S. Miyazaki: Acta Mater. 2006, vol. 54, pp. 423-433.

A. Panigrahi, B. Sulkowski, T. Waitz, K. Ozaltin, W. Chrominski, A. Pukenas, J. Horky, M. Lewandowska, W. Skrotzki, M. Zehetbauer: J. Mech. Behav. Biomed., 2016, vol. 62, pp. 93-105.

[9] D. Raabe, K. Lüucke: Mater. Sci Tech., 1993, vol. 9, pp. 302-312.

S. Acharya, A.G. Panicker, D.V. Laxmi, S. Suwas, K. Chatterjee: Mater Des, 2019, vol. 164, pp. 107555.

Y. Yang, G. Li, G. Cheng, H. Wang, M. Zhang, F. Xu, K. Yang: Scr. Mater., 2008, vol. 58 pp. 9-12.

B. Sander, D. Raabe: Mater. Sci. Eng. A, 2008, vol. 479, pp. 236-247.

S. Hanada, T. Yoshio, O. Izumi: T Jpn I Met., 1986, vol. 27, pp. 496-503.

T. Leffers, R. Ray, Progr. Mater. Sci., 2009, vol. 54, pp. 351-396.

S. Mercier, L. Tóth, A. Molinari, Texture, Stress, and Microstructure, 1995, vol. 25, pp. 45-61.

H. Kim, Y. Ikehara, J. Kim, H. Hosoda, S. Miyazaki, Acta Mater., 2006, vol. 54, pp. 2419-2429.

V. Cojocaru, D. Raducanu, T. Gloriant, D. Gordin, I. Cinca: Mater. Sci. Eng. A, 2013, vol. 586, pp. 1-10.

M. Abdel-Hady, K. Hinoshita, H. Fuwa, Y. Murata, M. Morinaga, Mater. Sci. Eng. A, 2008, vol. 480, pp. 167-174.

N.P. Gurao, S. Suwas, Mater. Sci. Eng. A, 2009, vol. 504, pp. 24-35.

S. Wronski, M. Wrobel, A. Baczmanski, K. Wierzbanowski: Mater. Charact., 2013, vol. 77 pp. 116-126.

S. Suwas, N. Gurao, Comprehensive Materials Processing, 2014, vol. 3, pp. 81-106.

R. Lebensohn, C. Tomé, Los Alamos National Laboratory, 2007.

Q. Chen, A. Ngan, B. Duggan, Proc. Royal Soc. A, 2003, vol. 459, pp. 1661-1685.

C. Tome, G. Canova, U. Kocks, N. Christodoulou, J. Jonas, Acta metal., 1984, vol. 32, pp. 1637-1653.

Y. Yang, S. Wu, G. Li, Y. Li, Y. Lu, K. Yang, P. Ge, Acta Mater., 2010, vol. 58, pp. 2778-2787.

R. Talling, R. Dashwood, M. Jackson, D. Dye, Acta Mater. 2009, vol. 57, pp. 1188-1198.

T. Yano, Y. Murakami, D. Shindo, S. Kuramoto, Acta Mater., 2009, vol. 57, pp. 628-633.

[28] M. Besse, P. Castany, T. Gloriant, Acta Mater, 2011, vol. 59, pp. 5982-5988.

A.O. Hayama, J.F. Lopes, M.J.G. Da Silva, H.F. Abreu, R. Caram, Mater Des, 2014, vol. 60 pp. 653-660.

S. Acharya, A.G. Panicker, V. Gopal, S.S. Dabas, G. Manivasagam, S. Suwas and K. Chatterjee: Mater. Sci. Eng. C, 2020, vol. 110, pp. 110729.

M. Huh, O. Engler, D. Raabe, Texture, Stress, and Microstructure, 1995, vol. 24, pp. 225-237.

Q. Chen, M. Quadir, B. Duggan, Philos. mag., 2006, vol. 86, pp. 3633-3646.

A. Malin, M. Hatherly, Met. Sci., 1979, vol. 13, pp. 463-472.

P. Jackson, Scr. metall., 1983, vol. 17, pp. 199-202.

B. Bay, N. Hansen, D. Hughes, D. Kuhlmann-Wilsdorf, Acta metal. mater., 1992, vol. 40, pp. 205-219.

I. Dillamore, J. Roberts, A. Bush, Met. Sci., 1979, vol. 13, pp. 73-77.

[37] S. Mahesh, Acta Mater. 2006, vol. 54, pp. 4565-4574.

S. Acharya, S. Bahl, K. Chatterjee, S. Suwas, Materialia, 2018, vol. 4, pp. 20-32.

J. Luster, M. Morris, Metall. Mater. Trans. A, 1995, vol. 26, pp. 1745-1756.

T. Bieler, P. Eisenlohr, F. Roters, D. Kumar, D. Mason, M. Crimp, D. Raabe, Int. J Plasticity, 2009, vol. 25, pp. 1655-1683.

M. Takenaka, N. Fujita, Y. Hayakawa, N. Tsuji, Acta Mater., 2018, vol. 157, pp. 196-208.

S. Hanada, M. Ozeki, O. Izumi, Metall. Trans A, 1985, vol. 16, pp. 789-795.

H. Tobe, H.Y. Kim, T. Inamura, H. Hosoda, S. Miyazaki, Acta Mater., 2014, 64: 345-355.

S. Suwas, R. Ray, Metall. Mater. Trans. A, 2000, vol. 31 pp. 2339-2350.

D. Raabe, K. Lücke, Z Metalkd, 1994, vol. 85, pp. 302-306.

P. Welch, G. Davies, Texture, Stress, and Microstructure, 1983, vol. 6, pp. 21-37.

R. Ray, J.J. Jonas, R. Hook, Int. mater. rev., 1994, vol. 39, pp. 129-172.

L. Toth, A. Molinari, D. Raabe, Metall. Mater. Trans. A, 1997, vol. 28, 2343-2351.

E. Pang, E. Pickering, S.-I. Baik, D.N. Seidman, N.G. Jones, Acta Mater, 2018, vol. 153, pp. 62-70.

Y. Hao, S. Li, S. Sun, R. Yang, Mater. Sci. Eng. A, 2006, vol. 441, pp. 112-118.

H. Xing, J. Sun, Appl. Phys. Lett., 2008, vol. 93, pp. 031908.

M.J. Lai, T. Li, D. Raabe, Acta Mater., 2018, vol. 151, 67-77.

Y. Yang, G. P. Li, G. M. Cheng, Y. L. Li, K. Yang, Appl. Phys. Lett., 2009, vol. 94, 061901.

A. Böcker, H. Klein, H. Bunge, Texture, Stress, and Microstructure, 1990, vol. 12, pp. 103-123.

Acknowledgments

The authors acknowledge the Department of Science and Technology (DST-SERB), India, for funding this work. The authors would also like to thank Dr. Amit Bhattacharya, Scientist, Defence Metallurgical Research Laboratory, Hyderabad, India, for his crucial support towards this work through many useful discussions. Authors gratefully acknowledge Dr. C.N. Tome and Dr. R.A. Lebensohn for providing VPSC7 code. SA acknowledges the contribution of Hritwik Kumar, summer intern at IISc Bangalore and undergraduate student at IIEST Shibpur, India, in preparation of samples for characterization. The extensive use of microscopes at the Advanced Facility of Microscopy and Microanalysis (AFMM) facility and XRD at the Institute X-ray facility, Indian Institute of Science, Bangalore, is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 15, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Acharya, S., Mishra, S., Yazar, K.U. et al. Evolution of Deformation Texture in Low Modulus β Ti-34Nb-2Ta-(0, 3)Zr-0.5O Alloys. Metall Mater Trans A 51, 4045–4058 (2020). https://doi.org/10.1007/s11661-020-05850-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05850-w