Abstract

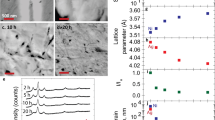

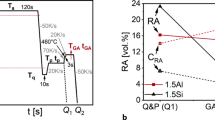

An attempt has been made to estimate the amount and composition of different phases formed during the simulated quenching and nonisothermal partitioning (Q&P) process in a dilatometer by matching the experimental dilation data with empirically determined dilation curve. The result highlights the carbon enrichment of austenite, as well as its partial transformation to secondary martensite and/or bainite, during the partitioning step. Also, an increase in quench temperature (QT) led to enhanced bainite or secondary martensite formation, as a result of reduced carbon enrichment of remaining austenite. Further Q&P experiments on bulk samples were carried out to understand the dependence of carbon diffusion and subsequent microstructure evolution with QT. Although the change in experimentally obtained retained austenite (RA) content with QT corroborates with the existing model predictions, the maximum amount of RA was observed at QT lower than predicted. The half-thickness of RA films increased with increasing QT, which substantiates the theoretical prediction of the diffusion distance of carbon atoms in austenite.

Similar content being viewed by others

References

1. X. Tan, Y. Xu, X. Yang, Z. Liu, and D. Wu: Mater. Sci. Eng. A, 2014, vol. 594, pp. 149-160.

G.A. Thomas: Simulation of hot-rolled advanced high strength sheet steel production using a Gleeble system, MS Thesis, Colorado School of Mines, Golden, Co, 2009.

3. G.A. Thomas, J.G. Speer, and D.K. Matlock: Metall. Mater. Trans. A, 2011, vol. 42, pp. 3652–3659.

4. X.D. Tan, Y.B. Xu, X.L. Yang, Z.P. Hu, F. Peng, X.W. Ju, and D. Wu, Mater. Charact., 2015, vol. 104, pp. 23-30.

5. Y. Li, X.Li, G. Yuan, J. Kang, D. Chen, and G. Wang: Mater. Charact., 2016, vol. 121, pp. 157-165.

6. Y. Li, D. Chen, X.Li, J. Kang, G.Yuan, R.D.K. Misra, and G.Wang: Steel Res. Int., 2018, vol. 89, pp. 1-11.

7. G.K. Bansal, V. Rajinikanth, C. Ghosh, V.C. Srivastava, S. Kundu, and S.G. Chowdhury: Metall. Mater. Trans. A, 2018, vol. 49, pp. 3501-3514.

8. Y.J. Li, J. Kang, W.N. Zhang, D. Liu, X.H. Wang, G. Yuan, R.D.K. Misra, and G.D. Wang: Mater. Sci. Eng. A, 2018, vol. 710, pp. 181-191.

K. Jian, W. Chao, L. Yunjie, Y. Guo, W. Guodong: J. Wuhan Univ. Technol., 2016, vol. 31, pp. 178-185.

10. Y. J. Li, D. Chen, D. Liu, J. Kang, G. Yuan, Q. J. Mao, R.D.K. Misra, and G. D. Wang: Mater. Sci. Eng. A, 2018, vol. 732, pp. 298-310.

11. D.V. Edmonds and R.C. Cochrane: Metall. Trans. A, 1990, vol. 21, pp. 1527-1540.

12. R. Ranjan and S.B. Singh: Metall. Mater. Trans. A, 2018, vol. 49, pp. 88-93.

13. L.C.D. Fielding: Mater. Sci. Technol., 2013, vol. 29, pp. 383-399.

S.B. Singh: in Phase Transformations in Steels: Fundamentals and Diffusion-Controlled Transformations, E. Pereloma, D.V. Edmonds, eds., Woodhead Publishing Limited, Cambridge, 2012.

15. H.K.D.H. Bhadeshia and R.W.K. Honeycombe: Steels: Microstructure and Properties, Butterworth-Heinemann, Elsevier, Oxford, 2006.

16. F.G. Caballero, M.K. Miller, C. Garcia-Mateo, and J. Cornide: J. Alloys Compd., 2013, vol. 577, pp. S626-S630.

17. F.G. Caballero, M.K. Miller, C. Garcia-Mateo, J. Cornide, and M.J. Santofimia: Scripta Mater., 2012, vol. 67, pp. 846-849.

18. S.M.C. van Bohemen, M.J. Santofimia, and J. Sietsma: Scr. Mater., 2008, vol. 58, pp. 488-491.

19. S. Samanta, P. Biswas, S. Giri, S.B. Singh, and S. Kundu: Acta Mater., 2016, vol. 105, pp. 390-403.

20. S. Samanta, S. Das, D. Chakrabarti, I. Samajdar, S.B. Singh, and A. Haldar: Metall. Mater. Trans. A, 2013, vol. 44, pp. 5653-5664.

21. M.J. Santofimia, L. Zhao, R. Petrov, C. Kwakernaak, W.G. Sloof, and J. Sietsma: Acta Mater., 2011, vol. 59, pp. 6059-6068.

22. F. HajyAkbary, J. Sietsma, G. Miyamoto, T. Furuhara, and M.J. Santofimia: Acta Mater., 2016, vol. 104, pp. 72-83.

23. J. Dearden and H. O’Neill: Trans. Inst. Weld, 1940, vol. 3, pp. 203-214.

24. K.W. Andrews: J. Iron Steel Inst., 1965, vol. 203, pp. 721-727.

25. J.G. Speer, A.M. Streicher, D.K. Matlock, F. Rizzo, and G. Krauss: Austenite formation and decomposition, Warrendale, TMS/ISS, 2003, pp. 505-522.

26. K.O. Findley, J. Hidalgo, R.M. Huizenga, and M.J. Santofimia: Mater. Des., 2017, vol. 117, pp. 248-256.

Y-J Yang, J-X Fu, R-J Zhao, and Y-X Wu: Dilatometric Analysis of Phase Fractions during Austenite Decomposition in Pipeline Steel, Proceedings of the 3rd International Conference on Material, Mechanical and Manufacturing Engineering (IC3ME), 2015, pp. 1974–78.

28. H.K.D.H. Bhadeshia, S.A. David, J.M. Vitek, and R. W. Reed: Mater. Sci. Technol., 1991, vol. 7, pp. 686-698.

29. D. J. Dyson and B. Holmes: J. Iron Steel Inst., 1970, vol. 208, pp. 469-474.

30. R. Wei, M. Enomoto, R. Hadian, H.S. Zurob, and G.R. Purdy: Acta Mater., 2013, vol. 61, pp. 697-707.

31. Y. Lu, H. Yu, and R.D. Sisson Jr, Mater. Sci. Eng. A, 2017, vol. 700, pp. 592-597.

32. J. Speer, D.K. Matlock, B.C. De Cooman, and J.G. Schroth: Acta Mater., 2003, vol. 51, pp. 2611-2622.

33. W. Stevens and A.J. Haynes: J. Iron Steel Inst., 1956, vol. 183, pp. 349-359.

34. H-S Yang and H.K.D.H. Bhadeshia: Mater. Sci. Technol., 2007, vol. 23, pp. 556-560.

35. D. Koistinen and R. Marburger: Acta Metall., 1959, vol. 7, pp. 59-60.

36. G.K. Bansal, M. Pradeep, C. Ghosh, V. Rajinikanth, V.C. Srivastava, A.N. Bhagat, and S. Kundu: Metall. Mater. Trans. A Comm., 2019, vol. 50, pp. 547-55.

37. S. Nagakura: J. Phys. Soc. Jpn., 1959, vol. 14, pp. 186-195.

38. S. Naseema, G.K. Bansal, M. Ghosh, G. Das, V.C. Srivatsava, K.S. Rao, and K.G. Krishna, Adv. Mater. Res., 2018, vol. 1148, pp. 75-81.

39. G.K. Bansal, V.C. Srivastava, and S. Ghosh Chowdhury, Mater. Sci. Eng. A, 2019, vol. 767, art. no. 138419.

40. M. Kizilyalli, J. Corish, and R. Metsellar: Pure Appl. Chem., 1999, vol. 71, pp. 1307-1325.

41. M.J. Santofimia, L. Zhaoa, and J. Sietsma: Scr. Mater., 2008, vol. 59, pp. 159-162.

42. M.J. Santofimia, J.G. Speer, A.J. Clarke, L. Zhao, and J. Sietsma: Acta Mater., 2009, vol. 57, pp. 4548–4557.

D. De Knijf, M. J. Santofimia, H. Shi, V. Bliznuk, C. Föjer, R. Petrova, and W. Xu: Acta Mater., 2015, vol. 90, pp. 161-168.

Acknowledgments

This work was financially supported by Tata Steel Ltd., Jamshedpur. The authors wish to thank the Director, CSIR-NML and Tata Steel management for their kind encouragement and permission to publish this work. The authors also acknowledge the help rendered by Prof. Javad Mola, Hochschule Osanabrück, Germany, in carrying out the dilatometry. The authors are also thankful to Dr. Saurav Kundu, TATA Steel for his suggestions during technical discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 30, 2019.

Rights and permissions

About this article

Cite this article

Bansal, G.K., Junior, L.P., Ghosh, C. et al. Quench Temperature-Dependent Phase Transformations During Nonisothermal Partitioning. Metall Mater Trans A 51, 3410–3424 (2020). https://doi.org/10.1007/s11661-020-05779-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05779-0