Abstract

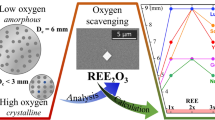

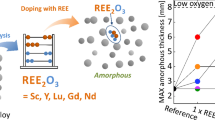

Oxygen sensitiveness of Zr-based bulk metallic glasses (BMGs) is well known and has a huge detrimental effect decreasing the alloy glass-forming ability (GFA) as well as mechanical properties. Addition of rare earth elements has been widely used in attempt to overcome this drawback. Here, we present an effective method to enhance the GFA of Vitreloy 105 along five different oxygen concentrations in the range from 600 to 3000 wppm by stoichiometric Y microalloying to form Y2O3 in samples with 5 and 6 mm diameter rods. Oxygen measurements, light optical microscopy (LOM), scanning electron microscopy (SEM) in backscattered electron (BSE) mode along with energy dispersive spectroscopy (EDS), and Rietveld refinement in synchrotron X-ray diffraction patterns were used to quantitatively demonstrate the effectiveness of the stoichiometric Y microalloying methodology to enhance the GFA in this alloy. This result opens the possibility of using less expensive low-purity raw materials in the production of BMGs with good sizes (5 and 6 mm rods) without the need of extreme cooling rates and clean conditions.

Similar content being viewed by others

References

Z.P. Lu, C.T. Liu and W.D. Porter: Appl. Phys. Lett., 2003, vol. 83, pp. 2581-2583. https://doi.org/10.1063/1.1614833.

F.F. Wu, K.C. Chan, S.-S. Jiang, S.-H. Chen and G. Wang: Sci. Rep., 2014, vol. 4, pp. 5302. https://doi.org/10.1038/srep05302.

A. Inoue, B. Shen and A. Takeuchi: Mater. Trans., 2006, vol. 47, pp. 1275-1285. https://doi.org/10.2320/matertrans.47.1275.

S.F. Guo, K.C. Chan, X.Q. Jiang, H.J. Zhang, D.F. Zhang, J.F. Wang, B. Jiang and F.S. Pan: J. Non. Cryst. Solids, 2013, vol. 379, pp. 107-111. https://doi.org/10.1016/j.jnoncrysol.2013.07.036.

Y. Liu, S. Niu, F. Li, Y. Zhu and Y. He: Powder Technol., 2011, vol. 213, pp. 36-40. https://doi.org/10.1016/j.powtec.2011.06.026.

Y. Fukushima, K. Katsumata, Z. Shengli, X. Guoqiang, M. Niinomi, K. Okada and N. Matsushita: Mater. Trans., 2013, vol. 54, pp. 1343-1346. https://doi.org/10.2320/matertrans.mf201312.

Z. Liu, Y. Yang, R. Li, L. Huang and T. Zhang: Chinese Sci. Bull., 2012, vol. 57, pp. 3931-3936. https://doi.org/10.1007/s11434-012-5293-x.

Y. Yokoyama, K. Fukaura and A. Inoue: Mater. Sci. Eng. A., 2004, vol. 375-377, pp. 427-431. https://doi.org/10.1016/j.msea.2003.10.268.

Q. Hu, M.W. Fu and X.R. Zeng: J. Alloys Compd., 2014, vol. 602, pp. 326-330. https://doi.org/10.1016/j.jallcom.2014.02.160.

J.-L. Cheng, G. Chen, C.-T. Liu and Y. Li: Sci. Rep., 2013, v. 3, pp. 2097. https://doi.org/10.1038/srep02097

C.T.T. Liu, M.F.F. Chisholm and M.K.K. Miller: Intermetallics, 2002, vol. 10,pp. 1105-1112. https://doi.org/10.1016/s0966-9795(02)00131-0.

M. Yan, J. Zou and J. Shen: Acta Mater., 2006, vol. 54, pp. 3627-3635. https://doi.org/10.1016/j.actamat.2006.03.052.

J. Zhu, C. Wang, J. Han, S. Yang, G. Xie, H. Jiang, Y. Chen and X. Liu: Intermetallics, 2018, vol. 92, pp. 55-61. https://doi.org/10.1016/j.intermet.2017.08.018.

M. Yan, J. Shen, T. Zhang and J. Zou: J. Non. Cryst. Solids, 2006, vol. 352, pp. 3109-3112. https://doi.org/10.1016/j.jnoncrysol.2006.02.098.

J. Luo, H. Duan, C. Ma, S. Pang and T. Zhang: Mater. Trans., 2006, vol. 47, pp. 450-453. https://doi.org/10.2320/matertrans.47.450.

N.D. Campos Neto, C. Soares, F.S. Pereira, V. Bergamaschi, S.G. Antonio, M.J. Kaufman and M.F. de Oliveira: J. Non. Cryst. Solids, 2020, 528, 119762. https://doi.org/10.1016/j.jnoncrysol.2019.119762

N.D. Campos Neto, W.M. de Paula, F.S. Pereira, C.J. Parrish and M.F. de Oliveira: Mater. Res., 2018, 21(6): e20171088. https://doi.org/10.1590/1980-5373-mr-2017-1088

R. Mackay, G.J. Miller and H.F. Franzen: J. Alloys Comp., 1994, 204(1-2), 109-118. https://doi.org/10.1016/0925-8388(94)90079-5

N.J. Clark and E. Wu: J. Less-Com. Met., 1990, vol. 163, pp. 227-243. https://doi.org/10.1016/0022-5088(90)90589-C

M.G. Paton and E.N. Maslen: Acta Cryst., 1965, vol.19, pp. 307. https://doi.org/10.1107/S0365110X65003365

Y. Zhang, M.X. Pan, D.Q. Zhao, R.J. Wang and W.H. Wang: Mater. Trans. JIM, 2000, v. 41, n. 11, pp. 1410-1414. https://doi.org/10.2320/matertrans1989.41.1410

W.J. Peng and Y. Zhang: Progr. Nat. Sci. 2011, 21(1), 46-52 https://doi.org/10.1016/S1002-0071(12)60024-0

J.J. Wall, J.D. Almer, S.C. Vogel, P.K. Liaw, H. Choo and C.T. Liu: Scr. Mater., 2009, vol. 61, pp. 293-295. https://doi.org/10.1016/j.scriptamat.2009.04.004

N.D. Campos Neto, F.S. Pereira, S.G. Antonio, Y. Guo, A.J. Clarke, M.J. Kaufman and M.F. de Oliveira: Mater. Charac., 2019, 158, 109932 https://doi.org/10.1016/j.matchar.2019.109932

W.H. Wang, Z. Bian, P. Wen, Y. Zhang, M.X. Pan and D.Q. Zhao: Intermetallics, 2002, v. 10, n. 11–12, pp. 1249-1257. https://doi.org/10.1016/S0966-9795(02)00140-1

Acknowledgments

The authors would like to thank the LNLS for provision of synchrotron radiation facilities and specially Dra. Cristiane Barbieri Rodella for assistance at the XPD beamline. We also thank FAPESP, CNPq, and CAPES for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 6, 2019.

Rights and permissions

About this article

Cite this article

de Campos Neto, N.D., de Carvalho Lopes Rocha, R.F., Pereira, F.S. et al. Effective Method to Enhance the Glass-Forming Ability of Vitreloy 105 Containing High Oxygen Concentrations. Metall Mater Trans A 51, 3518–3525 (2020). https://doi.org/10.1007/s11661-020-05775-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05775-4