Abstract

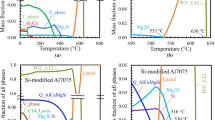

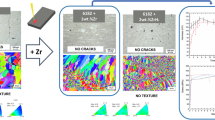

Additive manufacturing (AM) technology for metallic alloys such as laser powder bed fusion (LPBF) brings tremendous opportunities for development of novel alloys specifically designed for AM that would desensitize the inherent process variability and requires a refined understanding of processing–structure–property relationship that would contribute to future alloy development. In this study, two different alloys, Al-6Zn-2Mg and Al-6Zn-2Mg-0.7Sc-0.3Zr in wt. pct, representing traditional and AM-specific novel aluminum alloys, respectively, were manufactured by LPBF technique using pre-alloyed gas atomized powders. The Al-Zn-Mg ternary alloys exhibited cracks at various LPBF processing parameters, primarily along the grain boundaries of the large columnar grains that extended across multiple melt pools. The severity of cracking in LPBF Al-Zn-Mg alloys was process-dependent and could be correlated to the change in alloy composition due to evaporation of Zn and Mg with high vapor pressure. The Scheil–Gulliver non-equilibrium solidification calculations showed that the Al-Zn-Mg alloys with lower Zn and Mg concentrations had smaller solidification range (i.e., ΔT) and steepness values (i.e., \( \left| {{\text{d}}T / {\text{d}}f_{\text{s}}^{1/2} } \right| \) near \( f_{\text{s}}^{1/2} = 1 \)), which corresponded to a lower cracking severity. On the other hand, no cracks were observed in Al-Zn-Mg-Sc-Zr alloys, although their solidification range and steepness values were similar to the ternary Al-Zn-Mg alloys. The microstructure of Al-Zn-Mg-Sc-Zr alloys exhibited a much refined heterogeneous microstructure containing small equiaxed and columnar grains within each melt pool, owing to the heterogeneous nucleation upon primary Al3(Sc,Zr) particles. Process-dependent microstructure was observed as a result of variation in thermal gradient and cooling rate associated with LPBF parameters. Findings from this study provide guidance for the future design of AM-specific aluminum alloys and insights into the microstructural control by LPBF.

Similar content being viewed by others

References

N. T. Aboulkhair, M. Simonelli, L. Parry, I. Ashcroft, C. Tuck and R. Hague, Progress in Materials Science 2019, vol. 106, pp. 1-45.

L. Zhou, A. Mehta, E. Schulz, B. McWilliams, K. Cho and Y. Sohn, Materials Characterization 2018, vol. 143, pp. 5-17.

J. Delahaye, J. T. Tchuindjang, J. Lecomte-Beckers, O. Rigo, A. Habraken and A. Mertens, Acta Materialia 2019, vol. 175, pp. 160-170.

N. T. Aboulkhair, C. Tuck, I. Ashcroft, I. Maskery and N. M. Everitt, Metallurgical and Materials Transactions A 2015, vol. 46, pp. 3337-3341.

D. Koutny, D. Palousek, L. Pantelejev, C. Hoeller, R. Pichler, L. Tesicky and J. Kaiser, Materials 2018, vol. 11, pp. 1-18.

B.A. Fulcher, D.K. Leigh, and T.J. Watt: Proc. Solid Freeform Fabrication (SFF) Symposium. 2014.

P. Skalický, D. Koutný, L. Pantělejev, and D. Palousek: Proc. 58th ICMD 2017. 2017.

T. Qi, H. Zhu, H. Zhang, J. Yin, L. Ke and X. Zeng, Materials & Design 2017, vol. 135, pp. 257-266.

N. Kaufmann, M. Imran, T. Wischeropp, C. Emmelmann, S. Siddique and F. Walther, Physics Procedia 2016, vol. 83, pp. 918-926.

A. Mauduit, S. Pillot and H. Gransac, University Politehnica of Bucharest Scientific Bulletin Series B-Chemistry and Materials Science 2017, vol. 79, pp. 219-238.

L. Zhou, H. Hyer, S. Park, H. Pan, Y. Bai, K. P. Rice and Y. Sohn, Additive Manufacturing 2019, vol. 28, pp. 485-496.

S. Z. Uddin, L. E. Murr, C. A. Terrazas, P. Morton, D. A. Roberson and R. B. Wicker, Additive Manufacturing 2018, vol. 22, pp. 405-415.

I. Raffeis, F. Adjei-Kyeremeh, U. Vroomen, P. Suwanpinij, S. Ewald and A. Bührig-Polazcek, JOM 2019, pp. 1-11.

M. L. M. Sistiaga, R. Mertens, B. Vrancken, X. Wang, B. Van Hooreweder, J.-P. Kruth and J. Van Humbeeck, Journal of Materials Processing Technology 2016, vol. 238, pp. 437-445.

H. Zhang, H. Zhu, X. Nie, J. Yin, Z. Hu and X. Zeng, Scripta Materialia 2017, vol. 134, pp. 6-10.

X. Nie, H. Zhang, H. Zhu, Z. Hu, L. Ke and X. Zeng, Journal of Alloys and Compounds 2018, vol. 764, pp. 977-986.

J. H. Martin, B. D. Yahata, J. M. Hundley, J. A. Mayer, T. A. Schaedler and T. M. Pollock, Nature 2017, vol. 549, pp. 365-369.

A. Spierings, K. Dawson, T. Heeling, P. Uggowitzer, R. Schäublin, F. Palm and K. Wegener, Materials & Design 2017, vol. 115, pp. 52-63.

A. B. Spierings, K. Dawson, M. Voegtlin, F. Palm and P. J. Uggowitzer, CIRP Annals-Manufacturing Technology 2016, vol. 65, pp. 213-216.

L. Zhou, H. Pan, H. Hyer, S. Park, Y. Bai, B. McWilliams, K. Cho and Y. Sohn, Scripta Materialia 2019, vol. 158, pp. 24-28.

J. R. Croteau, S. Griffiths, M. D. Rossell, C. Leinenbach, C. Kenel, V. Jansen, D. N. Seidman, D. C. Dunand and N. Q. Vo, Acta Materialia 2018, vol. 153, pp. 35-44.

Q. Jia, P. Rometsch, P. Kürnsteiner, Q. Chao, A. Huang, M. Weyland, L. Bourgeois and X. Wu, Acta Materialia 2019, vol. 171, pp. 108-118.

T. Kimura and T. Nakamoto, Materials & Design 2016, vol. 89, pp. 1294-1301.

C. Galy, E. Le Guen, E. Lacoste and C. Arvieu, Additive Manufacturing 2018, vol. 22, pp. 165-175.

S. A. Khairallah, A. T. Anderson, A. Rubenchik and W. E. King, Acta Materialia 2016, vol. 108, pp. 36-45.

W. E. King, H. D. Barth, V. M. Castillo, G. F. Gallegos, J. W. Gibbs, D. E. Hahn, C. Kamath and A. M. Rubenchik, Journal of Materials Processing Technology 2014, vol. 214, pp. 2915-2925.

R. Xiao and X. Zhang, Journal of Manufacturing Processes 2014, vol. 16, pp. 166-175.

K. V. Yang, Y. Shi, F. Palm, X. Wu and P. Rometsch, Scripta Materialia 2018, vol. 145, pp. 113-117.

N. Coniglio, C. E. Cross, T. Michael and M. Lammers, Welding Journal 2008, vol. 87, pp. 237s-247s.

S. Kou, Acta Materialia 2015, vol. 88, pp. 366-374.

S. Liu, H. Zhu, G. Peng, J. Yin and X. Zeng, Materials & Design 2018, vol. 142, pp. 319-328.

P. Promoppatum, S.-C. Yao, P. C. Pistorius and A. D. Rollett, Engineering 2017, vol. 3, pp. 685-694.

Y. Lee and W. Zhang, Additive Manufacturing 2016, vol. 12, pp. 178-188.

D. Rosenthal, Welding journal 1941, vol. 20, pp. 220-234.

S. Kou, Welding Metallurgy, 2nd edn. (John Wiley & Sons, 2003)

Acknowledgment

This research was sponsored by the CCDC Army Research Laboratory under a cooperate agreement contract, W911NF1720172. The views, opinions, and conclusions made in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the CCDC Army Research Laboratory or the US Government. The US Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation herein. The authors would also like to thank Katherine P. Rice at CAMECA Instruments Inc. for assistance with EBSD data acquisition.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 11, 2019.

Rights and permissions

About this article

Cite this article

Zhou, L., Hyer, H., Thapliyal, S. et al. Process-Dependent Composition, Microstructure, and Printability of Al-Zn-Mg and Al-Zn-Mg-Sc-Zr Alloys Manufactured by Laser Powder Bed Fusion. Metall Mater Trans A 51, 3215–3227 (2020). https://doi.org/10.1007/s11661-020-05768-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05768-3