Abstract

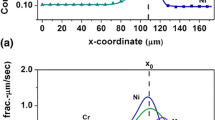

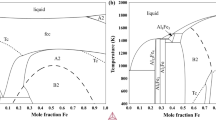

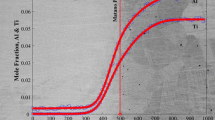

High entropy and sluggish diffusion “core” effects were investigated in an FCC Al-Co-Cr-Fe-Ni alloy by examining the nonequiatomic compositions generated by the concentration profiles within the solid-to-solid diffusion couple, Al48Ni52vs Co25Cr25Fe25Ni25, annealed at 900 °C, 1000 °C, 1100 °C, and 1200 °C. The average effective interdiffusion coefficients of individual components and the maximum solubility limit of Al in nonequiatomic Al-Co-Cr-Fe-Ni alloys were determined as a function of temperature. The magnitudes of the average effective interdiffusion coefficients in Al-Co-Cr-Fe-Ni alloys were compared to the interdiffusion coefficients in relevant ternary and quaternary alloys. The solubility limit of Al in nonequiatomic AlpCoqCrrFesNit alloys was compared to that of Al in equiatomic AlxCoCrFeNi determined from the equilibrium pseudo-binary phase diagram. A reduction in the magnitude of interdiffusion coefficients was not observed for individual components in Al-Co-Cr-Fe-Ni alloys. The maximum solubility of Al in nonequiatomic AlpCoqCrrFesNit alloys was observed to be higher than that in equiatomic AlxCoCrFeNi alloys at a temperature of 1100 °C or above. Correspondingly, the free energy of mixing for nonequiatomic AlpCoqCrrFesNit alloys was determined to be lower than that of equiatomic AlxCoCrFeNi alloys at a temperature of 1100 °C or above. At a temperature of 1100 °C or above, the role of enthalpy of mixing was estimated to be significant in achieving higher thermodynamic stability of the nonequiatomic AlpCoqCrrFesNit alloy than in the equiatomic AlxCoCrFeNi alloy for the compositions corresponding to the highest solubility limit for Al. The compositions of nonequiatomic AlpCoqCrrFesNit alloys were observed to follow the existing empirical rules for the formation of single phase in high entropy alloys (HEAs).

Similar content being viewed by others

References

J.W. Yeh: Ann. Chim. Sci. Mater., 2006, vol. 31, pp. 633–48.

E. Pickering and N. Jones: Int. Mater. Rev., 2016, vol. 61, pp. 183–202.

W.R. Wang, W.L. Wang, S.C. Wang, Y.C. Tsai, C.H. Lai, and J.W. Yeh: Intermetallics, 2012, vol. 26, pp. 44–51.

J. He, W. Liu, H. Wang, Y. Wu, X. Liu, T. Nieh, and Z. Lu: Acta Mater., 2014, vol. 62, pp. 105–13.

Y. Guo, L. Liu, Y. Zhang, J. Qi, B. Wang, Z. Zhao, J. Shang, and J. Xiang: J. Mater. Res., 2018, vol. 33, pp. 3258–65.

F. Zhang, C. Zhang, S.-L. Chen, J. Zhu, W.-S. Cao, and U.R. Kattner: CALPHAD, 2014, vol. 45, pp. 1–10.

F. Otto, Y. Yang, H. Bei, and E.P. George: Acta Mater., 2013, vol. 61, pp. 2628–38.

K.Y. Tsai, M.H. Tsai, and J.W. Yeh: Acta Mater., 2013, vol. 61, pp. 4887–97.

M. Vaidya, S. Trubel, B. Murty, G. Wilde, and S.V. Divinski: J. Alloys Compd., 2016, vol. 688, pp. 994–1001.

M. Vaidya, K. Pradeep, B. Murty, G. Wilde, and S. Divinski: Acta Mater., 2018, vol. 146, pp. 211–24.

M. Vaidya, K. Pradeep, B. Murty, G. Wilde, and S. Divinski: Scient. Rep., 2017, vol. 7, pp. 1–11.

J. Dąbrowa, W. Kucza, G. Cieślak, T. Kulik, M. Danielewski, and J.-W. Yeh: J. Alloys Compd., 2016, vol. 674, pp. 455–62.

D. Beke and G. Erdélyi: Mater. Lett., 2016, vol. 164, pp. 111–13.

T.R. Paul, I.V. Belova, and G.E. Murch: Mater. Chem. Phys., 2018, vol. 210, pp. 301–08.

A. Allnatt, T. Paul, I. Belova, and G. Murch: Phil. Mag., 2016, vol. 96, pp. 2969–85.

K. Kulkarni and G.P.S. Chauhan: AIP Adv., 2015, vol. 5, pp. 1–7.

V. Verma, A. Tripathi, and K.N. Kulkarni: J. Phase Equil. Diffus., 2017, vol. 38, pp. 445–56.

A. Mehta, L. Zhou, E.A. Schulz, D.D. Keiser, J.I. Cole, and Y. Sohn: J. Phase Equil. Diffus., 2018, vol. 39, pp. 246–54.

Y. Park, R. Newell, A. Mehta, D. Keiser, Jr., and Y. Sohn: J. Nucl. Mater., 2018, vol. 502 pp. 42–50.

E.A. Schulz, A. Mehta, I.V. Belova, G.E. Murch, and Y. Sohn: J. Phase Equil. Diffus., 2018, vol. 39, pp. 862–69.

L. Onsager: Ann. New York Acad. Sci., 1945, vol. 46, pp. 241–65.

M. Dayananda and C. Kim: Metall. Mater. Trans. A, 1979, vol. 10A, pp. 1333–39.

J.S. Kirkaldy: Can. J. Phys., 1957, vol. 35, pp. 435–40.

M. Dayananda and Y. Sohn: Scripta Mater., 1996, vol. 35, pp. 683–88.

D. Liu, L. Zhang, Y. Du, H. Xu, and Z. Jin: J. Alloys Compd., 2013, vol. 566, pp. 156–63.

K. Cheng, D. Liu, L. Zhang, Y. Du, S. Liu, and C. Tang: J. Alloys Compd., 2013, vol. 579, pp. 124–31.

Q. He, Y. Ye, and Y. Yang: J. Appl. Phys., 2016, vol. 120, pp. 1–10.

Q. He, Y. Ye, and Y. Yang: J. Phase Equil. Diffus., 2017, vol. 38, pp. 416–25.

H. Bakker: Enthalpies in Alloys: Miedema’s Semi-Empirical Model, Enfield Publishing & Distribution Company, Enfield, NH, 1998.

A. Takeuchi and A. Inoue: Mater. Trans., 2005, vol. 46, pp. 2817–29.

I. Ford: Statistical Physics: An Entropic Approach, 1st ed., John Wiley & Sons, Hoboken, NJ, 2013.

S. Fang, X. Xiao, L. Xia, W. Li, and Y. Dong: J. Non-Cryst. Solids, 2013, vol. 321, pp. 120–25.

A. Takeuchi and A. Inoue: Mater. Trans., JIM, 2000, vol. 41, pp. 1372–78.

X. Yang and Y. Zhang: Mater. Chem. Phys., 2012, vol. 132, pp. 233–38.

U. Mizutani: Hume-Rothery Rules for Structurally Complex Alloy Phases, CRC Press, Boca Raton, FL, 2016.

S. Guo, C. Ng, J. Lu, and C. Liu: J. Appl. Phys., 2011, vol. 109, pp. 1–5.

J.G. Duh and M.A. Dayananda: Diffus. Def. Data, 1985, vol. 39, pp. 1–50.

Y.F. Kao, T.J. Chen, S.K. Chen, and J.W. Yeh: J. Alloys Compd., 2009, vol. 488, pp. 57–64.

M. Komarasamy, T. Wang, K. Liu, L. Reza-Nieto, and R.S. Mishra: Scripta Mater., 2019, vol. 162, pp. 38–43.

S. Guo, Q. Hu, C. Ng, and C. Liu: Intermetallics, 2013, vol. 41, pp. 96–103.

M. Poletti and L. Battezzati: Acta Mater., 2014, vol. 75, pp. 297–306.

X. Yang, S. Chen, J. Cotton, and Y. Zhang: JOM, 2014, vol. 66, pp. 2009–20.

Y. Dong, Y. Lu, L. Jiang, T. Wang, and T. Li: Intermetallics, 2014, vol. 52, pp. 105–09.

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw: Adv. Eng. Mater., 2008, vol. 10, pp. 534–38.

M.X. Ren, B.S. Li, and H.Z. Fu: Trans. Nonferr. Met. Soc. China, 2013, vol. 23, pp. 991–95.

A. Takeuchi, K. Amiya, T. Wada, K. Yubuta, W. Zhang, and A. Makino: Entropy, 2013, vol. 15, pp. 3810–21.

L. Jiang, Y. Lu, H. Jiang, T. Wang, B. Wei, Z. Cao, and T. Li: Mater. Sci. Technol., 2016, vol. 32, pp. 588–92.

D. Miracle and O. Senkov: Acta Mater., 2017, vol. 122, pp. 448–511.

A.K. Singh, N. Kumar, A. Dwivedi, and A. Subramaniam: Intermetallics, 2014, vol. 53, pp. 112–19.

Y. Ye, Q. Wang, J. Lu, C. Liu, and Y. Yang: Scripta Mater., 2015, vol. 104, pp. 53–55.

D. King, S. Middleburgh, A. McGregor, and M. Cortie: Acta Mater., 2016, vol. 104, pp. 172–79.

Z. Wang, Y. Huang, Y. Yang, J. Wang, and C. Liu: Scripta Mater., 2015, vol. 94, pp. 28–31.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 10, 2019.

Rights and permissions

About this article

Cite this article

Mehta, A., Sohn, Y. Interdiffusion, Solubility Limit, and Role of Entropy in FCC Al-Co-Cr-Fe-Ni Alloys. Metall Mater Trans A 51, 3142–3153 (2020). https://doi.org/10.1007/s11661-020-05742-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05742-z