Abstract

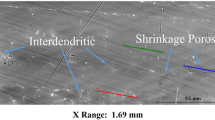

We studied the morphological and crystallographic properties of Ni-based single-crystal superalloys, addressing their surface and near-surface structural evolutions upon robotic hammer peening (RHP) by employing surface profiling, X-ray diffraction, scanning electron microscopy, and electron backscatter diffraction. By varying the diameter (DHH) of the spherical hammer head and the driving pressure (PRHP), we found that the RHP process with the increased DHH and PRHP tends to improve the surface smoothness and, meanwhile, reduce the RHP-induced step height at the boundary between the peened and unpeened areas, especially on the surface with a deformed layer caused by wire electrical discharge machining (EDM). The surface step height can also be reduced by removing the EDM-deformed layer before the RHP process. Straight and crosshatching DSTs were observed in the transition zones surrounding the peened area, where none or minor crystal reorientations occurred. In comparison, the RHP-induced crystal reorientation is much more significant in the peened area and the reorientation direction is associated with the surface normal direction, i.e., the compression loading axis of the RHP process. The RHP-induced crystal reorientations are discussed and attributed to the non-Schmid behavior associated with multiple cross-slips of superalloys under dynamic compressive loadings.

Similar content being viewed by others

References

A. Azhari, S. Sulaiman, and A.K.P. Rao: IOP Conf. Ser.: Mater. Sci. Eng., 2016, vol. 114, pp. 012002-1–012002-10.

S.-H. Han, J.-W. Han, Y.-Y. Nan, and I.-H. Cho: Fatig. Fract. Eng. Mater. Struct., 2009, vol. 32, pp. 573–79.

F. Bleicher, C. Lechner, C. Habersohn, E. Kozeschnik, B. Adjassoho, and H. Kaminski: CIRP Annals, 2012, vol. 61, pp. 375–78.

V. Schulze, F. Bleicher, P. Groche, Y.B. Guo, and Y.S. Pyun: CIRP Annals, 2016, vol. 65, pp. 809–32.

C. Kanger, H. Hadidi, S. Akula, C. Sandman, J. Quint, M. Alsunni, R. Underwood, C. Slafter, J. Sonderup, M. Spilinek, J. Casias, P. Rao, and M.P. Sealy: Effect of Process Parameters and Shot Peening on Mechanical Behavior of ABS Parts Manufactured by Fused Filament Fabrication (FFF), 2017, pp. 444–58.

W. Guo, R. Sun, B. Song, Y. Zhu, F. Li, Z. Che, B. Li, C. Guo, L. Liu, and P. Peng: Surf. Coat. Technol., 2018, vol. 349, pp. 503–10.

R. Sun, L. Li, Y. Zhu, W. Guo, P. Peng, B. Cong, J. Sun, Z. Che, B. Li, C. Guo, and L. Liu: J. Alloys Compd., 2018, vol. 747, pp. 255–65.

B. AlMangour and J.-M. Yang: Mater. Des., 2016, vol. 110, pp. 914–24.

N.E. Uzan, S. Ramati, R. Shneck, N. Frage, and O. Yeheskel: Addit. Manufact., 2018, vol. 21, pp. 458–64.

D. Thibault, R. Simoneau, J. Lanteigne, and J.-L. Fihey: Mater. Sci. Forum, 2005, vols. 490–491, pp. 352–57.

B. Hazel, J. Côté, Y. Laroche, and P. Mongenot: In-Situ Robotic Interventions in Hydraulic Turbines, 2010, pp. 1–6.

B. Hazel, J. Côté, Y. Laroche, and P. Mongenot: J. Field Robotics, 2012, vol. 29, pp. 102–22.

M. Segersäll: Research Thesis, Linköping University, Linköping, Sweden, 2013.

R. Hashizume, A. Yoshinari, T. Kiyono, Y. Murata, and M. Morinaga: Energy Mater., 2007, vol. 2, pp. 5–12.

A. Morancais, M. Fevre, M. Francois, N. Guel, S. Kruch, P. Kanoute, and A. Longuet: J. Appl. Crystallogr., 2015, vol. 48, pp. 1761–76.

G.X. Lu, J.D. Liu, H.C. Qiao, Y.Z. Zhou, T. Jin, X.F. Sun, and Z.Q. Hu: J. Alloys Compd., 2016, vol. 658, pp. 721–25.

C. Yang: J. Mech. Sci. Technol., 2005, vol. 19, pp. 802–10.

R.L. Fleischer: J. Mech. Phys. Solids, 1958, vol. 6, pp. 301–06.

Z. Liu, H. Zhong, Y. Wang, S. Li, and H. Fu: J. Mater. Res., 2018, vol. 33, pp. 2796–2805.

E.F. Westbrooke, L.E. Forero, and F. Ebrahimi: Acta Mater., 2005, vol. 53, pp. 2137–47.

P. Zhang, Y. Yuan, B. Li, S.W. Guo, G.X. Yang, and X.L. Song: Mater. Sci. Eng.: A, 2016, vol. 655, pp. 152–59.

R.V. Miner, T.P. Gabb, J. Gayda, and K. Hemker: Metall. Mater. Trans. A, 1986, vol. 17A, pp. 507–12.

A. Nitz, U. Lagerpusch, and E. Nembach: Acta Mater., 1998, vol. 46, pp. 4769–79.

Y. Chen and C. Jiang: Mater. Trans., 2013, vol. 54, pp. 1894–97.

A. Morancais, M. Fevre, M. François, P. Kanoute, S. Kruch, and A. Longuet: Adv. Mater. Res., 2014, vol. 996, pp. 70–75.

R. Pippan and A. Hohenwarter: Fatig. Fract. Eng. Mater. Struct., 2017, vol. 40, pp. 471–95.

A. Wang, P.F. Thomson, and P.D. Hodgson: J. Mater. Process. Technol., 1996, vol. 60, pp. 95–102.

B. Zhao, Y. Lv, Y. Ding, L. Wang, and W. Lu: Mater. Charact., 2018, vol. 144, pp. 77–85.

M. Guagliano: J. Mater. Processing Technol., 2001, vol. 110, pp. 277–86.

D. Bettge and W. Österle: Scripta Mater., 1999, vol. 40, pp. 389–95.

H. Gao and Y. Huang: Scripta Mater., 2003, vol. 48, pp. 113–18.

G. Winther: Acta Mater., 2008, vol. 56, pp. 1919–32.

B. Liu, D. Raabe, F. Roters, and A. Arsenlis: Acta Mater., 2014, vol. 79, pp. 216–33.

J. Jiang, T. Zhang, F.P.E. Dunne, and T.B. Britton: Proc. R. Soc. A: Mathem., Phys. Eng. Sci., 2016, vol. 472, pp. 20150690-1–20150690-24.

H. Chen, J.W. Kysar, and Y.L. Yao: J. Appl. Mech., 2004, vol. 71, pp. 713–23.

D.P. Pope and S.S. Ezz: Int. Met. Rev., 1984, vol. 29, pp. 136–67.

Acknowledgments

This work was supported by an A*STAR RIE2020 advanced manufacturing and engineering (AME) programmatic grant through the structural metal alloys program (SMAP, Grant No. A18B1b0061).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted on December 16, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, H., Tan, C.K.I., Cheng, W.S. et al. Effects of Robotic Hammer Peening on Structural Properties of Ni-Based Single-Crystal Superalloy: Dislocation Slip Traces and Crystallographic Reorientations. Metall Mater Trans A 51, 3180–3193 (2020). https://doi.org/10.1007/s11661-020-05734-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05734-z