Abstract

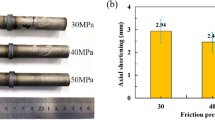

An elementary analysis is proposed to quantify the effects of ultrasonic vibrations during friction stir welding (FSW) of AA6061-T6 to AZ31B Mg alloy. In the present context, the ultrasonic vibrations are applied in the stirred zone (SZ) via a specially designed welding tool. The influence of ultrasonic vibration has been analyzed for a wide range of welding and rotation speeds. The acoustic addition has proven beneficial to enhance joint strength. Significant diminutions in axial downward force, tool torque, and tool input power equal to ~ 38, 38.7, and 38.75 pct, respectively, have been observed during the ultrasonic addition. Melioration in interfacial bonding, enhanced material mixing, and an improvement in weldment surface quality are observed for ultrasonic joints. For conventional joints, the intermetallic phases βAl3Mg2 and γAl12Mg17 have been found in the SZ and are fragmented under the acoustic influence. The microstructural analysis of the fracture surface shows a ductile fracture mechanism at ultrasonically treated surfaces. A noteworthy grain refinement cum recrystallization is observed in the SZ as well as the immediate deformation zone. The maximum ultrasonic effects are apparent at the weld center and gradually diminish as they move ahead from it.

Similar content being viewed by others

References

L. Liu, D. Ren, and F. Liu: Materials (Basel), 2014, vol. 7, pp. 3735–57.

S. Kumar and C.S. Wu: J. Harbin Inst. Technol. (New Ed.), 2017, vol. 24, pp. 1–37.

P. Liu, Y. Li, H. Geng, and J. Wang: Mater. Lett., 2007, vol. 61, pp. 1288–91.

Y. Zhao, Z. Lu, K. Yan, and L. Huang: Mater. Des., 2015, vol. 65, pp. 675–81.

J. Wang, J.C. Feng, and Y.X. Wang: Mater. Sci. Technol., 2008, vol. 24, pp. 827–31.

B. Meyghani, M.B. Awang, S. Emamian, and E.T. Akinlabi: Materwiss. Werksttech., 2018, vol. 49, pp. 427–34.

V. Buchibabu, G.M. Reddy, D. Kulkarni, and A. De: J. Mater. Eng. Perform., 2016, vol. 25, pp. 1163–71.

S. Kumar, W. Ding, Z. Sun, and C.S. Wu: Int. J. Adv. Manuf. Technol., 2018, vol. 97, pp. 1269–84.

Y.C. Chen and K. Nakata: Scripta Mater., 2008, vol. 58, pp. 433–36.

X.Q. Lv, C.S. Wu, C.L. Yang, and G.K. Padhy: J. Mater. Process. Technol., 2018, vol. 254, pp. 145–57.

J. Peng, Z. Zhang, J. Huang, P. Guo, Y. Li, W. Zhou, and Y. Wu: J. Alloys Compd., 2019, vol. 792, pp. 16–24.

A. Dorbane, B. Mansoor, G. Ayoub, V.C. Shunmugasamy, and A. Imad: Mater. Sci. Eng. A, 2016, vol. 651, pp. 720–33.

M. Czechowski: J. Mater. Process. Technol., 2005, vol. 164, pp. 1001–06.

V. Firouzdor and S. Kou: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 2914–35.

M. Simoncini and A. Forcellese: Mater. Des., 2012, vol. 41, pp. 50–60.

J. Verma, R.V. Taiwade, C. Reddy, and R.K. Khatirkar: Mater. Manuf. Process., 2018, vol. 33, pp. 308–14.

L. Giraud, H. Robe, C. Claudin, C. Desrayaud, P. Bocher, and E. Feulvarch: J. Mater. Process. Technol., 2016, vol. 235, pp. 220–30.

A. Kostka, R.S. Coelho, J. dos Santos, and A.R. Pyzalla: Scripta Mater., 2009, vol. 60, pp. 953–56.

U.F.H. Suhuddin, V. Fischer, and J.F. Dos Santos: Scripta Mater., 2013, vol. 68, pp. 87–90.

Y.S. Sato, S.H.C. Park, M. Michiuchi, and H. Kokawa: Scripta Mater., 2004, vol. 50, pp. 1233–36.

M.A. Mofid, A. Abdollah-Zadeh, and C.H. Gür: Int. J. Adv. Manuf. Technol., 2014, vol. 71, pp. 1493–99.

S. Ji, R. Huang, X. Meng, L. Zhang, and Y. Huang: J. Mater. Eng. Perform., 2017, vol. 26, pp. 2359–67.

S. Benfer, B. Straß, G. Wagner, and W. Fürbeth: Surf. Interface Anal., 2016, vol. 48, pp. 843–52.

B. Strass, G. Wagner, C. Conrad, B. Wolter, S. Benfer, and W. Fürbeth: Adv. Mater. Res., 2014, vols. 966–967, pp. 521–35.

K. Park: Development and Analysis of Ultrasonic Assisted Friction Stir Welding Process. PhD Dissertation, 2009.

S. Kumar: Arch. Civ. Mech. Eng., 2016, vol. 16, pp. 473–84.

S. Kumar, C.S. Wu, Z. Sun, and W. Ding: Int. J. Adv. Manuf. Technol., 2019, vol. 100, pp. 1787–99.

S. Kumar and C.S. Wu: Mater. Today Proc., 2018, vol. 5, pp. 18142–18151.

S. Kumar and C. Wu: J. Alloys Compd., 2020. https://doi.org/10.1016/j.jallcom.2020.154343.

F. Ning, H. Wang, W. Cong, and P.K.S.C. Fernando: Ultrasonics, 2017, vol. 76, pp. 44–51.

P.K.S.C. Fernando, M. Zhang, and Z. Pei: Mach. Sci. Technol., 2019, vol. 23, pp. 595–611.

C. Xu, G. Sheng, X. Cao, and X. Yuan: J. Mater. Sci. Technol., 2016, vol. 32, pp. 1253–59.

S. Ji, X. Meng, Z. Liu, R. Huang, and Z. Li: Mater. Lett., 2017, vol. 201, pp. 173–76.

S. Kumar, C.S. Wu, and G.K. Padhy: 7th Int. Conf. on Welding Science and Engineering (WSE 2017) in Conjunction with 3rd International Symposium on Computer-Aided Welding Engineering (CAWE 2017), Shandong University, Jinan, China, 2017, pp. 272–76.

A. Banik, J.D. Barma, and S.C. Saha: Iran J. Sci. Technol. Trans. Mech. Eng., https://doi.org/10.1007/s40997-019-00289-w.

P. Venkateswaran, Z.H. Xu, X. Li, and A.P. Reynolds: J. Mater. Sci., 2009, vol. 44, pp. 4140–47.

R. Fonda, J. Bingert, and K. Colligan: Scripta Mater., 2004, vol. 51, pp. 243–48.

T. McNelley, S. Swaminathan, and J. Su: Scripta Mater., 2008, vol. 58, pp. 349–54.

W. Xunhong and W. Kuaishe: Mater. Sci. Eng. A, 2006, vol. 431, pp. 114–17.

G.K. Padhy, C.S. Wu, and S. Gao: Mater. Des., 2017, vol. 116, pp. 207–18.

G.K. Padhy, C.S. Wu, S. Gao, and L. Shi: Mater. Des., 2016, vol. 92, pp. 710–23.

Y.S. Sato, M. Urata, H. Kokawa, and K. Ikeda: Mater. Sci. Eng. A, 2003, vol. 354, pp. 298–305.

M. Ahmadnia, A. Seidanloo, R. Teimouri, Y. Rostamiyan, and K.G. Titrashi: Int. J. Adv. Manuf. Technol., 2015, vol. 78, pp. 2009–24.

X.C. Liu, C.S. Wu, and G.K. Padhy: Sci. Technol. Weld. Join., 2015, vol. 20, pp. 345–52.

L. Shi, C.S. Wu, and X.C. Liu: J. Mater. Process. Technol., 2015, vol. 222, pp. 91–102.

V. Firouzdor and S. Kou: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 3238–51.

J. Philibert: Mater. Sci. Forum, 1994, vols. 155–156, pp. 15–30.

Y. Chen and K. Nakata: Mater. Des., 2009, vol. 30, pp. 469–74.

S. Malarvizhi and V. Balasubramanian: Mater. Des., 2012, vol. 40, pp. 453–60.

A.C. Somasekharan and L.E. Murr: J. Mater. Sci., 2006, vol. 41, pp. 5365–70.

S.H. Chowdhury, D.L. Chen, S.D. Bhole, X. Cao, and P. Wanjara: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 323–36.

R. Nandan, G.G. Roy, T. Debroy, and I. Introduction: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1247–59.

N.Z. Khan, A.N. Siddiquee, Z.A. Khan, and A.K. Mukhopadhyay: J. Alloys Compd., 2017, vol. 695, pp. 2902–08.

A. Kouadri-Henni and L. Barrallier: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 4983–96.

S.H. Chowdhury, D.L. Chen, S.D. Bhole, X. Cao, and P. Wanjara: Mater. Sci. Eng. A, 2012, vol. 556, pp. 500–09.

K.-J. Lee and E.-P. Kwon: Trans. Nonferrous Met. Soc. China, 2014, vol. 24, pp. 2374–79.

S.H.C. Park, Y.S. Sato, and H. Kokawa: Scripta Mater., 2003, vol. 49, pp. 161–66.

I. Dinaharan and N. Murugan: Mater. Sci. Eng. A, 2012, vol. 543, pp. 257–66.

S. Alireza Askariani, H. Pishbin, and M. Moshref-Javadi: J. Alloys Compd., 2017, vol. 724, pp. 859–68.

X.C. Liu and C.S. Wu: J. Mater. Process. Technol., 2015, vol. 225, pp. 32–44.

S. Kumar, C.S. Wu, G.K. Padhy, and W. Ding: J. Manuf. Process., 2017, vol. 26, pp. 295–322.

X.C. Liu, C.S. Wu, and G.K. Padhy: Scripta Mater., 2015, vol. 102, pp. 95–98.

V. Gaur, M. Enoki, T. Okada, and S. Yomogida: Int. J. Fatigue, 2018, vol. 107, pp. 119–29.

T. Wen, L. Wei, X. Chen, and C.L. Pei: Int. J. Miner. Metall. Mater., 2011, vol. 18, pp. 70–76.

S. Kumar and C.S. Wu: 5th Int. Symp. on Visualization in Joining & Welding Science through Advanced Measurements and Simulation and 8th Int. Conf. of Welding Science and Engineering, Osaka, Japan, 2019.

Acknowledgment

The authors acknowledge the financial support from the Key R&D Program of Shandong Province in China (Grant No. 2018GGX103001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 1, 2019.

Rights and permissions

About this article

Cite this article

Kumar, S., Wu, C. & Gao, S. Process Parametric Dependency of Axial Downward Force and Macro- and Microstructural Morphologies in Ultrasonically Assisted Friction Stir Welding of Al/Mg Alloys. Metall Mater Trans A 51, 2863–2881 (2020). https://doi.org/10.1007/s11661-020-05716-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05716-1