Abstract

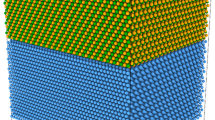

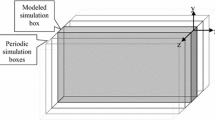

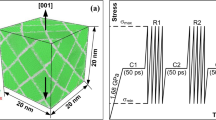

Molecular dynamics (MD) is employed to simulate the mechanical response of Al/Fe interface under compression at extreme conditions of seven temperatures and four strain rates ranging between 150 K and 900 K and 5.0 × 107 s−1 and 1.0 × 1010 s−1, respectively. Stress–strain histories show two distinct yield stress points for simulations at temperatures below 500 K, which tend to merge into one as the temperature increases. Microstructural simulations show nucleation of dislocations, which occur in the bulk of the aluminum region, is associated with the first yield point. In the iron region, dislocations nucleate at the Al/Fe interface and are associated with the second yield point. The incoherent interface employed in these simulations contributes to the heterogeneous nucleation in iron by creating a defected area favorable for this nucleation from the aluminum side. MD generated data show that the two yield stresses and the consequent flow stress decrease with increasing temperature for all strain rates and fit a thermally activated model function of strain rate. The competing mechanisms between dislocation motion and phonon drag driven deformation are also simulated and modeled. The flow stress of the interface was found to fall midway between Zerilli–Armstrong models of the two materials constituting it, whereas the relaxation in Fe followed similar trend to what is reported in the literature.

Similar content being viewed by others

References

B. Gurrutxaga-Lerma, M.A. Shehadeh, D.S. Balint, D. Dini, L. Chen, and D.E. Eakins: Int. J. Plast., 2017, vol. 96, pp. 135–55.

A.P. Gerlich, L. Yue, P.F. Mendez, and H. Zhang: Acta Mater., 2010, vol. 58, pp. 2176–85.

P. Gupta and N. Yedla: Procedia Eng., 2017, vol. 184, pp. 631–6.

A. Dutta: Acta Mater., 2017, vol. 125, pp. 219–30.

M. Yaghoobi and G.Z. Voyiadjis: Acta Mater., 2018, vol. 151, pp. 1–10.

G. Sainath, B.K. Choudhary, and T. Jayakumar: Comput. Mater. Sci., 2015, vol. 104, pp. 76–83.

G. Sainath and B.K. Choudhary: Mater. Sci. Eng. A, 2015, vol. 640, pp. 98–105.

G. Sainath and B.K. Choudhary: Comput. Mater. Sci., 2016, vol. 111, pp. 406–15.

M. Tang and J. Marian: Acta Mater., 2014, vol. 70, pp. 123–9.

P. El Ters and M.A. Shehadeh: Int. J. Plast., 2019, vol. 112, pp. 257–77.

R.F. Smith, J.H. Eggert, R.E. Rudd, D.C. Swift, C.A. Bolme, and G.W. Collins: J. Appl. Phys., 2011, vol. 110, pp. 123515.

B.A. Remington, P. Allen, E.M. Bringa, J. Hawreliak, D. Ho, K.T. Lorenz, H. Lorenzana, J.M. McNaney, M.A. Meyers, S.W. Pollaine, K. Rosolankova, B. Sadik, M.S. Schneider, D. Swift, J. Wark, and B. Yaakobi: Mater. Sci. Technol., 2006, vol. 22, pp. 474–88.

T. De Rességuier and M. Hallouin: J. Appl. Phys., 1998, vol. 84, pp. 1932–8.

R. Becker, A. Arsenlis, G. Hommes, J. Marian, M. Rhee, and L.H. Yang: A Tantalum Strength Model Using a Multiscale Approach : Version 2, Livermore, CA, 2009.

H. Shu, X. Huang, H. Pan, J. Ye, F. Zhang, G. Jia, Z. Fang, Y. Tu, Z. Xie, and S. Fu: Int. J. Fract., 2017, vol. 206, pp. 81–93.

R.W. Armstrong, W. Arnold, and F.J. Zerilli: J. Appl. Phys., 2009, vol. 105, pp. 1–8.

Z. El Chlouk, W. Kassem, M. Shehadeh and R. Hamade, American University of Beirut, Beirut, Unpublished research, 2020.

I.N. Mastorakos, A. Bellou, D.F. Bahr, and H.M. Zbib: J. Mater. Res., 2011, vol. 26, pp. 1179–87.

R. Kohlhaas, P. Dunner, and N. Schmitz-Pranghe: Zeitschrift fur Angew. Phys., 1967, vol. 23, pp. 245–9.

W. Witt: Zeitschrift fur Naturforsch. - Sect. A J. Phys. Sci., 1967, vol. 22, pp. 92–5.

S. Shao and S.N. Medyanik: Mech. Res. Commun., 2010, vol. 37, pp. 315–9.

M.I. Mendelev, D.J. Srolovitz, G.J. Ackland, and S. Han: J. Mater. Res., 2005, vol. 20, pp. 208–18.

R.G. Hoagland, J.P. Hirth, and A. Misra: Philos. Mag., 2006, vol. 86, pp. 3537–58.

J. Vallin, M. Mongy, K. Salama, and O. Beckman: J. Appl. Phys., 1964, vol. 35, pp. 1825–6.

E. Goens and E. Schmid: Zeitschrift für Elektrochemie und Angew. Phys. Chemie, 1931, vol. 37, pp. 539–40.

S. Queyreau, J. Marian, M.R. Gilbert, and B.D. Wirth: Phys. Rev. B - Condens. Matter Mater. Phys., 2011, vol. 84, pp. 1–7.

L. Liu, Q. Deng, M. Su, M. An, and R. Wang: Superlattices Microstruct., 2019, vol. 135, p. 106272.

T. Zhu, J. Li, A. Samanta, A. Leach, and K. Gall: Phys. Rev. Lett., 2008, vol. 100, pp. 1–4.

D. Caillard and J.L. Martin: Thermally Activated Mechanisms in Crystal Plasticity, 1st edn., Elsevier Science, Oxford, UK, 2003, pp. 23-26.

R.W. Armstrong and Q. Li: Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2015, vol. 46, pp. 4438–53.

J.W. Swegle and D.E. Grady: J. Appl. Phys., 1985, vol. 58, pp. 692–701.

J.C. Crowhurst, M.R. Armstrong, K.B. Knight, J.M. Zaug, and E.M. Behymer: Phys. Rev. Lett., 2011, vol. 107, pp. 1–5.

F.J. Zerilli and R.W. Armstrong: J. Appl. Phys., 1987, vol. 61, pp. 1816–25.

G.T. Gray, S.R. Chen, W. Wright, and M.F. Lopez: New Mex. los Alamos Natl. Lab., 1994, pp. 21–8.

Acknowledgments

The authors wish to acknowledge the financial support of the university research board (URB) of the American University of Beirut.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 06, 2019.

Rights and permissions

About this article

Cite this article

El Chlouk, Z.G., Shehadeh, M.A. & Hamade, R.F. The Effect of Strain Rate and Temperature on the Mechanical Behavior of Al/Fe Interface Under Compressive Loading. Metall Mater Trans A 51, 2573–2589 (2020). https://doi.org/10.1007/s11661-020-05709-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05709-0