Abstract

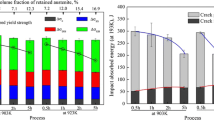

Although third-generation advanced high-strength steels have achieved a great combination of high ultimate tensile strength and ductility, edge cracking has been frequently reported during their cold forming of components. Following this issue, the effects of the stability, the morphology, and the amount of retained austenite (RA) on fracture resistance have already been investigated. However, the influence of the size and distribution of blocky RA and/or martensite (RA/M) islands on fracture resistance is absent, which is deliberately addressed in this study. After austenitization, the effect of holding temperatures between 278 °C and 400 °C on microstructure evolution in a Fe-0.3C-2.5Mn-1.5Si-0.8Cr (wt pct) steel is systematically and quantitatively investigated. Tensile properties and fracture resistance are characterized using uniaxial tension and double edge-notched tension tests, which interestingly show that an increased product of ultimate tensile strength and total elongation is accompanied with a decreased fracture resistance. This is because that tensile properties are mainly affected by the stability and amount of RA while the fracture resistance is also affected by the size and distribution of blocky RA/M islands. A coarse size of and a small interspacing between blocky RA/M islands are detrimental to the fracture resistance due to the promotion of crack nucleation and crack propagation.

Similar content being viewed by others

References

[1] Z.P. Xiong, A.G. Kostryzhev, N.E. Stanford, and E.V. Pereloma: Mater. Des., 2015, vol. 88, pp. 537-49.

[2] Z.P. Xiong, A.G. Kostryzhev, A.A. Saleh, L. Chen, and E.V. Pereloma: Mater. Sci. Eng. A, 2016, vol. 664, pp. 26-42.

[3] O. Grässel, L. Krüger, G. Frommeyer, and L.W. Meyer: Int. J. Plast., 2000, vol. 16, pp. 1391-1409.

[4] Z.P. Xiong, X.P. Ren, J. Shu, Z.L. Wang, W.P. Bao and S.X. Shu: J. Iron Steel Res. Int., 2015, vol. 22, pp. 179-84.

[5] F. Caballero and H. Bhadeshia: Curr. Opin. Solid State Mater. Sci., 2004, vol. 8, pp. 251-57.

[6] D. Edmonds, K. He, F. Rizzo, B. de Cooman, D. Matlock, and J. Speer: Mater. Sci. Eng. A, 2006, vol. 438, pp. 25-34.

[7] X. Gui, G. Gao, H. Guo, F. Zhao, Z. Tan, and B. Bai: Mater. Sci. Eng. A, 2017, vol. 684, pp. 598-605.

[8] K.W. Kim, K.I. Kim, C.H. Lee, J.Y. Kang, T.H. Lee, K.M. Cho, and K.H. Oh: Mater. Sci. Eng. A, 2016, vol. 673, pp. 557-61.

[9] J. Speer, D. Matlock, B. de Cooman, and J. Schroth: Acta Mater., 2003, vol. 51, pp. 2611-22.

[10] H. Bhadeshia and D. Edmonds: Metal Sci., 1983, vol. 17, pp. 411-19.

[11] E. de Moor, J.G. Speer, D.K. Matlock, J.H. Kwak, and S.B. Lee: ISIJ Int., 2011, vol. 51, pp. 137-44.

[12] L. Kučerová, H. Jirková, and B. Mašek: Arch. Metall. Mater., 2014, vol. 59, pp. 1189-92.

[13] F.G. Caballero, J.D. Poplawsky, H.W. Yen, R. Rementeria, L. Morales-Rivas, J.R. Yang, and C. García-Mateo: Mater. Sci. Forum, 2017, vol. 878, pp. 2401-06.

[14] X.Y. Long, J. Kang, B. Lv, and F.C. Zhang: Mater. Des., 2014, vol. 64, pp. 237-45.

[15] B. Avishan, S. Yazdani, F. Caballero, T. Wang, and C. Garcia-Mateo: Mater. Sci. Technol., 2015, vol. 31, pp. 1508-20.

[16] P. Jacques, Q. Furnemont, T. Pardoen, and F. Delannay: Acta Mater., 2001, vol. 49, pp. 139-52.

[17] G. Lacroix, T. Pardoen, and P.J. Jacques: Acta Mater., 2008, vol. 56, pp. 3900-13.

[18] I. de Diego-Calderón, I. Sabirov, J. Molina-Aldareguia, C. Föjer, R. Thiessen, and R. Petrov: Mater. Sci. Eng. A, 2016, vol. 657, pp. 136-46.

[19] R. Wu, W. Li, S. Zhou, Y. Zhong, L. Wang, and X. Jin: Metall. Mater. Trans. A, 2014, vol. 45, pp. 1892-1902.

[20] G. Gao, H. Zhang, X. Gui, P. Luo, Z. Tan, and B. Bai: Acta Mater., 2014, vol. 76, pp. 425-33.

[21] Z.P. Xiong, P.J. Jacques, A. Perlade, and T. Pardoen: Metall. Mater. Trans. A, 2019, vol. 50, pp. 3502-13.

[22] Q. Zhou, L. Qian, J. Tan, J. Meng, and F. Zhang: Mater. Sci. Eng. A, 2013, vol. 578, pp. 370-76.

[23] H. Lan, L. Du, Q. Li, C. Qiu, J. Li, and R. Misra: J. Alloys Compd., 2017, vol. 710, pp. 702-10.

[24] J. Kobayashi, D. Ina, N. Yoshikawa, and K.I. Sugimoto: ISIJ Int., 2012, vol. 52, pp. 1894-1901.

[25] S. van Bohemen: Mater. Sci. Technol., 2012, vol. 28, pp. 487-95.

[26] G. K. Bansal, M. Pradeep, C. Ghosh, V. Rajinikanth, V. C. Srivastava, A. N. Bhagat and S. Kundu: Metall. Mater. Trans. A, 2019, vol. 50, pp. 547-55.

[27] M. Santofimia, L. Zhao, R. Petrov, C. Kwakernaak, W. Sloof, and J. Sietsma: Acta Mater., 2011, vol. 59, pp. 6059-68.

[28] N. van Dijk, A. Butt, L. Zhao, J. Sietsma, S. Offerman, J. Wright, and S. van der Zwaag: Acta Mater., 2005, vol. 53, pp. 5439-47.

[29] B. Cotterell and J. Reddel: Int.J. Fracture, 1977, vol. 13, pp. 267-77.

J. Rice, P. Paris, J. Merkle: Some further results of J-integral analysis and estimates, in: A.s.f.t.a. materials (Ed.) Progress in flaw growth and fracture toughness testing, ASTM International, Philadelphia, 1973, pp. 231-45.

[31] T.L. Anderson: Fracture mechanics: fundamentals and applications, fourth ed., CRC Press, Boca Raton. 2017.

[32] Z.P. Xiong, P.J. Jacques, A. Perlade, and T. Pardoen: Scripta Mater., 2018, vol. 157, pp. 6-9.

[33] Z. Xie, Y. Ren, W. Zhou, J. Yang, C. Shang, and R. Misra: Mater. Sci. Eng. A, 2014, vol. 603, pp. 69-75.

[34] M.J. Santofimia, L. Zhao, and J. Sietsma: Metall. Mater. Trans. A, 2011, vol. 42, pp. 3620-26.

[35] J.H. Chen, Y. Kikuta, T. Araki, M. Yoneda, and Y. Matsuda: Acta Metall., 1984, vol. 32, pp. 1779-88.

[36] C. Davis and J. King: Mater. Sci. Technol., 1993, vol. 9, pp. 8-15.

[37] D. Tian, L.P. Karjalainen, B. Qian, and X. Chen: JSME Int. J. Ser. A Mech. Mater. Eng., 1997, vol. 40, pp. 179-88.

[38] P. Huyghe, S. Dépinoy, M. Caruso, D. Mercier, C. Georges, L. Malet, and S. Godet: ISIJ Int., 2018, vol. 58, pp. 1341-50.

[39] X. Li, Y. Fan, X. Ma, S.V. Subramanian, and C. Shang: Mater. Des., 2015, vol. 67, pp. 457-63.

[40] F. Zia-Ebrahimi and G. Krauss: Metall. Mater. Trans. A, 1983, vol. 14, pp. 1109-19.

[41] Y.J. Zhao, X.P. Ren, Z.L. Hu, Z.P. Xiong, J.M. Zeng, and B.Y. Hou: Mater. Sci. Eng. A, 2018, vol. 711, pp. 397-404.

[42] F. Caballero, H. Bhadeshia, K. Mawella, D. Jones, and P. Brown: Mater. Sci. Technol., 2001, vol. 17, pp. 517-22.

[43] H. Guo, A. Zhao, R. Ding, C. Zhi, and J. He: Mater. Sci. Technol., 2016, vol. 32, pp. 1605-12.

[44] J. Zhang, H. Ding, R. Misra, and C. Wang: Mater. Sci. Eng. A, 2014, vol. 611, pp. 252-56.

[45] Y. Huang, Q. Li, X. Huang, and W. Huang: Mater. Sci. Eng. A, 2016, vol. 678, pp. 339-46.

Acknowledgments

This research is supported by ArcelorMittal Global R&D Maizières Products in France and Université catholique de Louvain in Belgium. Z.P.X thanks the “Beijing Institute of Technology Research Fund Program for Young Scholars.”

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 31, 2019.

Rights and permissions

About this article

Cite this article

Yang, D., Xiong, Z. The Dependence of Fracture Resistance on the Size and Distribution of Blocky Retained Austenite-Martensite Constituents. Metall Mater Trans A 51, 2072–2083 (2020). https://doi.org/10.1007/s11661-020-05698-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05698-0