Abstract

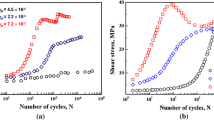

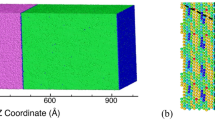

To explore the dependence of mechanical behavior on the crystal size, the \( [\bar{1}11] \)-oriented Cu single crystal was selected as a target material, and the variations of tensile and tension–tension fatigue behavior with the crystal specimen thickness (t) were systematically investigated. The results show that, with the decrease of t, the tensile yield strength continuously increases, especially as t < 0.4 mm, which is related to an enhanced role of surfaces in affecting dislocation activity; ultimate tensile strength first increases and elongation has almost no change as t is decreased from 2.0 to 1.0 mm, but with continuously decreasing t, both of them decrease; as t = 0.1 mm, the slight increases in ultimate tensile strength and elongation occur. With the decrease of t, the corresponding dislocation structures are evolved from the cell walls into the cells and tangles; meanwhile, the density of slip bands (SBs) decreases. Moreover, the obvious concentrated SB regions and notable cross-slip traces are clearly observed in thicker crystals. The fatigue life has no notable change as t = 2.0 and 1.0 mm, but increases subsequently with decreasing t due to the decrease in the plastic strain accumulation together with an enhanced interaction between the dislocations in the surface zone.

Similar content being viewed by others

References

E. Arzt: Acta Metall., 1998, vol. 46, pp. 5611-26.

X.H. Dong, X.T. Hong, F. Chen, B.R. Sang, W. Yu, and X.P. Zhang: Mater. Design, 2014, vol. 64, pp. 400-6.

X.X. Chen and A.H.W. Ngan: Scripta Mater., 2011, vol. 64, pp. 717-20.

M. Lederer, V. Gröger, G. Khatibi, and B. Weiss: Mater. Sci. Eng. A, 2010, vol. 527, pp. 590-9.

Y.H. Zhao, Y.Z. Guo, Q. Wei, T.D. Topping, A.M. Dangelewicz, T.T. Zhu, T.G. Langdon, and E.J. Lavernia: Mater. Sci. Eng. A, 2009, vol. 525, pp. 68-77.

A. Molotnikov, R. Lapovok, C.H.J. Davies, W. Cao, and Y. Estrin: Scripta Mater., 2008, vol. 59, pp. 1182-85.

G. Simons, C. Weippert, J. Dual, and J. Villain: Mater. Sci. Eng. A, 2006, vol. 416, pp. 290-9.

C. Howard, D. Frazer, A. Lupinacci, S. Parker, R.Z. Valiev, C. Shin, and B. William Choi: Mater. Sci. Eng. A, 2016, vol. 649, pp. 104-13.

H. Fang, R. Shiohara, T. Sumigawa, and T. Kitamura: Mater. Sci. Eng. A, 2014, vol. 618, pp. 416-23.

J.P. Wharry, K.H. Yano, and P.V. Patki: Scripta Mater., 2019, vol. 162, pp. 63-7.

H.D. Espinosa, B.C. Prorok, and B. Peng: J. Mech. Phys. Solids, 2004, vol. 52, pp. 667-89.

J.R. Greer and J.T.M. De Hosson: Prog. Mater. Sci., 2011, vol. 56, pp. 654-724.

S.H. Oh, M. Legros, D. Kiener, and G. Dehm: Nature Mater., 2009, vol. 8, pp. 95-100.

T.A. Parthasarathy, S.I. Rao, D.M. Dimiduk, M.D. Uchic, and D.R. Trinkle: Scripta Mater., 2007, vol. 56, pp. 313-16.

D. Kiener and A.M. Minor: Nano lett., 2011, vol. 11, pp. 3816-20.

G.P. Zhang, K.H. Sun, B. Zhang, J. Gong, C. Sun, and Z.G. Wang: Mater. Sci. Eng. A, 2008, vol. 483-484, pp. 387-90.

U. Engel and R. Eckstein: J. Mater. Process. Technol., 2002, vol. 125-126, pp. 35-44.

C.S. Han, A. Hartmaier, H.J. Gao, and Y.G. Huang: Mater. Sci. Eng. A, 2006, vol. 415, pp. 225-33.

C. Keller, E. Hug, and D. Chaterigner: Mater. Sci. Eng. A, 2009, vol. 500, pp. 207-15.

H. Bei, S. Shim, G.M. Pharr, and E.P. George: Acta Mater., 2008, vol. 56, pp. 4762-70.

Y. Yan, M. Lu, W.W. Guo, and X.W. Li: Mater. Sci. Eng. A, 2014, vol. 600, pp. 99-107.

D. Kiener, P. Hosemann, S.A. Maloy, and A.M. Minor: Nature Mater., 2011, vol. 10, pp. 608-13.

K.S. Ng and A.H.W. Ngan: Acta Mater., 2009, vol. 57, pp. 4902-10.

M.Q. Liu, Y.L. Liu, Y. Yan, D. Han, and X.W. Li: Cryst. Res. Technol., 2017, vol. 52, pp. 1700178.

S.H. Oh, M. Legros, D. Kiener, P. Gruber, and G. Dehm: Acta Mater., 2007, vol. 55, pp. 5558-71.

C. Keller, A.M. Habraken, and L. Duchene: Mater. Sci. Eng. A, 2012, vol. 550, pp. 342-9.

K. Kammuri, M. Kitamura, and T. Fujii: Mater. Trans., 2015, vol. 56, pp. 200-5.

Z.J. Zhou, T. Liu, S. Pu, H. Xu, L. Wang, and L.H. Lou: J. Alloy. Compd., 2015, vol. 647, pp. 802-8.

P. Li, S.X. Li, Z.G. Wang, and Z.F. Zhang: Prog. Mater. Sci., 2011, vol. 56, pp. 328-77.

S. Suresh: Fatigue of Materials, Cambridge University Press, Cambridge, 2001.

J.T. Gao, C. Principe, and J. Wang: J Mater. Proc. Technol., 2007, vol. 184, pp. 42-6.

H. Mughrabi: Mater. Sci. Eng. A, 2004, vol. 387-389, pp. 209-13.

X.W. Li, Z.G. Wang, and S.X. Li: Philo. Mag. Lett., 1999, vol. 79, pp. 869-75.

X.W. Li, W.P. Jia, Z.G. Wang, and S.X. Li: J. Mater. Sci. Lett., 2000, vol. 19, pp. 641-3.

Z. Wang, W.J. Romanow, and C. Laird: Metall. Trans. A, 1989, vol. 20, pp. 759-69.

J.R. Greer, W.C. Oliver, and W.D. Nix: Acta Mater., 2005, vol. 53, pp. 1821-30.

D.M. Dimiduk, M.D. Uchic, and T.A. Parthasarathy: Acta Mater., 2005, vol. 53, pp. 4065-77.

G. Richter, K. Hillerich, D.S. Gianola, R. Monig, O.Kraft, and C.A. Volkert: Nano Lett., 2009, vol. 9, pp. 3048-52.

B. Yang, C. Motz, M. Rester, and G. Dehm: Philos. Mag., 2012, vol. 92, pp. 3243-56.

C.Y. Dai, J. Xu, B. Zhang, and G.P. Zhang: Philo. Mag. Lett., 2013, vol. 93, pp. 531-40.

Y. Yan, G.Q. Zhang, L.J. Chen, and X.W. Li: Inter. J. Min. Metall. Mater., 2019, vol. 26, pp. 1450-5.

C.R. Weinberger and W. Cai: Proc. Natl. Acad. Sci., 2008, vol. 105, pp. 14304-7.

Z.X. Wang, H.J. Shi, and J. Lu: Theor. Appl. Fract. Mech., 2008, vol. 50, pp. 124-31.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China under Grant Nos. 51571058 and 51871048 and by the Open Foundation of Key Laboratory for Anisotropy and Texture of Materials, Ministry of Education, Northeastern University, China, under Grant No. ATM20170001. Prof. X.W. Li is grateful for this support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 14, 2019.

Rights and permissions

About this article

Cite this article

Yan, Y., Liu, Y.L., Liu, M.Q. et al. Thickness-Dependent Mechanical Behavior of 〈111〉-Oriented Cu Single Crystals. Metall Mater Trans A 51, 2044–2052 (2020). https://doi.org/10.1007/s11661-020-05689-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05689-1