Abstract

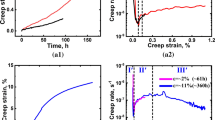

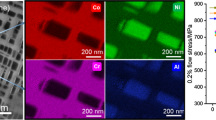

Three novel Co-30Ni-(7 − 1.5x)Al-2W-1.5Mo-1Ta-(3.5 + 0.7x)Ti-12Cr-0.1Hf-0.08C-0.08B-0.4Si-0.01Zr (x = 0, 1, 2 at. pct) γ′-strengthened wrought Co-based superalloys with varying concentrations of Al and Ti were investigated to clarify the effects of the Al and Ti concentration on the microstructural stability at 750 °C and 1000 °C. The results show that the 7Al-3.5Ti and 5.5Al-4.2Ti alloys maintain a γ/γ′ two-phase microstructure after aging at 1000 °C for 600 hours, but the 4Al-4.9Ti alloy forms a η(D024)-(Co,Ni)3Ti phase after aging at 1000 °C for 312 hours. There exist stacking faults in the γ′ phase adjacent to the D024 needles, which form during the aging process, and the growth of the η(D024) phase is controlled by the diffusion of W. The γ′ phase and η(D024)-(Co,Ni)3Ti phase exhibit the following OR: \( \left. {\left\langle { 1 1 {\bar{\text{2}}}0} \right\rangle \left\{ {000 1} \right\}\eta } \right\|\left\langle { 1 10} \right\rangle \left\{ { 1 1 1} \right\}\gamma \prime \). All the alloys possess good intermediate-temperature microstructural stability, with γ/γ′ two phases after aging at 750 °C for 1500 hours. With increasing Ti content and decreasing Al content, the coarsening rate of γ′ at 1000 °C first decreases and then increases; however, it gradually decreases at 750 °C. This difference in the coarsening behavior is attributed to the interaction of the interfacial energy, diffusion of the solute atoms and coherent stress.

Similar content being viewed by others

References

J. Sato, T. Omori, K. Oikawa, I. Ohnuma, R. Kainuma, K. Ishida: Science, 2006, vol. 312, pp. 90-1.

T.M. Pollock, J. Dibbern, M. Tsunekane, J. Zhu, A. Suzuki: JOM, 2010, vol. 62, pp. 58-63.

M. Tsunekane, A. Suzuki, T.M. Pollock: Intermetallics, 2011, vol. 19, pp. 636-43.

K. Shinagawa, T. Omori, J. Sato, K. Oikawa, I. Ohnuma, R. Kainuma, K. Ishida: Mater. Trans., 2008, vol. 49, pp. 1474-9.

F. Xue, H.J. Zhou, Q.Y. Shi, X.H. Chen, H. Chang, M.L Wang, Q. Feng: Scr. Mater., 2015, vol. 97, pp. 37-40.

G. Feng, H. Li, S.S. Li, J.B. Sha: Scr. Mater., 2012, vol. 67, pp. 499-502.

M. Ooshima, K. Tanaka, N.L. Okamoto, K. Kishida, H. Inui: J. Alloy. Compd., 2010, vol. 508, pp. 71-8.

F. Pyczak, A. Bauer, M. Göken, U. Lorenz, S. Neumeier, M. Oehring, J. Pual, N. Schell, A. Schreyer, A. Stark, F. Symanzik: J. Alloy. Compd., 2015, vol. 632, pp. 110-5.

L. Klein, A. Bauer, S. Neumeier, M. Göken, S. Virtanen: Corros. Sci., 2011, vol. 53, pp. 2027-34.

Li W, Li L, Antonov S, Feng Q.: Mater. Des., 2019, 180, pp. 107912.

S. Neumeier, L.P. Freund, M. Göken: Scr. Mater., 2015, vol. 109, pp. 104-7.

L.P. Freund, S. Giese, D. Schwimmer, H.W. Höppel, S. Neumeier, M. Göken: J. Mater. Res., 2017, vol. 32, pp. 1-8.

M. Knop, P. Mulvey, F. Ismail, A. Radecka, K.M. Rahman, T.C. Lindley, B.A. Shollock, M.C. Hardy, M.P. Moody, T.L. Martin, P.A.J. Bagot, D. Dye: JOM, 2014, vol. 66, pp. 2495-501.

Zhang Y, Fu HD, Zhou XZ, Zhang YH, Xie JX (2018) Mater. Sci. Eng. A 737:265-273.

C.H. Zenk, S. Neumeier, H.J. Stone, M. Göken: Intermetallics, 2014, vol. 55, pp. 28-39.

P.J. Bocchini, C.K. Sudbrack, R.D. Noebe, D.C. Dunand, D.N. Seidman: Mater. Sci. Eng. A, 2017, vol. 705, pp. 122-32.

Y.Z. Li, F. Pyczak, M. Oehring, L. Wang, J. Paul, U. Lorenz, Z.K. Yao: J. Alloy. Compd., 2017, vol. 729, pp. 266-76.

N. Volz, C.H. Zenk, R. Cherukuri, T. Kalfhaus, M. Weiser, S.K. Makineni, C. Betzing, M. Lenz, B. Gault, S.G. Fries, J. Schreuer, R. Vaßen, S. Virtanen, D. Raabe, E. Spiecker, S. Neumeier, M. Göken: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 4099-109.

L.P. Freund, A. Stark, A. Kirchmayer, N. Schell, F. Pyczak, M. Göken, S. Neumeier: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 4070-8.

Zhang Y, Fu HD, Zhou XZ, Zhang YH, Xie JX (2019) Intermetallics 112:106543.

C.J. Small, N. Saunders: MRS Bull., 1999, vol. 24, pp. 22-6.

E.A. Lass: Metall. Mater. Trans. A, 2017, vol. 48, pp. 2443-59.

Yan H-Y, Coakley J, Vorontsov VA, Jones NG, Stone HJ, Dye D (2014) Mater. Sci. Eng. A, 613, 201-8.

W.F. Gale, T.C. Totemeier: Smithells Metals Reference Book (8th Edition), 2004, Amsterdam: Elsevier.

E.W. Ross, C.T. Sims: Superalloys II. A Wiley-Interscience Publication, New York, 1987, pp. 97-133.

I.M. Lifshitz, V.V. Slyozov: J. Phys. Chem. Solids, 1961, vol. 19, pp. 35-50.

C. Wagner: Z. Elektrochem., 1961, vol. 65, pp. 581-91.

A.J. Ardell, V. Ozolins: Nat. Mater., 2005, vol. 4, pp. 309-16.

J. Tiley, G.B. Viswanathan, R. Srinivasan, R. Banerjee, D.M. Dimiduk, H.L. Fraser: Acta Mater., 2009, vol. 57, pp. 2538-49.

M. Fährmann, E. Fährmann, T.M. Pollock, W.C. Johnson: Metall. Mater. Trans. A, 1997, vol. 28, pp. 1943-5.

G.S Shin, J.Y. Yun, M.C. Park, S.J. Kim: Mater. Charact., 2014, vol. 95, pp. 180-6.

S. Meher, S. Nag, J Tiley, A. Goel, R. Banerjee: Acta Mater., 2013, vol. 61, pp. 4266-76.

S. Neumeier, H.U. Rehman, J. Neuner, C.H. Zenk, S. Michel, S. Schuwalow, J. Rogal, R. Drautz, M. Göken: Acta Mater., 2016, vol. 106, pp. 304-12.

A.J. Ardell, R.B. Nicholson: J. Phy. Chem. Solids., 1966, vol. 27, pp. 1793-804.

T. Hara, S. Kobayashi, T. Ueno, K. Oikawa: J. Cryst. Growth, 2019, vol. 506, pp. 91-6.

E. Balikci, D. Erdeniz: Metall. Mater. Trans. A, 2010, vol. 41, pp. 1391-8.

R.S. Moshtaghin, S. Asgari: Mater. Des., 2003, vol. 24, pp. 325-30.

C.Y. Cui, Y.F. Gu, D.H. Ping, H. Harada: Metall. Mater. Trans. A, 2009, vol. 40, pp. 282-91.

M. Kompatscher, B. Schönfeld, H. Heinrich, G. Kostorz: J. Appl. Cryst., 2000, vol. 33, pp. 488-91.

Mehrer H (ed) (1990) Diffusion in Solid Metals and Alloys, Landolt-börnstein New Series. Springer, Berlin

M.S. Titus, A. Mottura, G.B. Viswanathan, A. Suzuki, M.J. Mills, T.M. Pollock: Acta Mater., 2015, vol. 89, pp. 423-37.

T.M. Smith, B.S. Good, T.P. Gabb, B.D. Esser, A.J. Egan, L.J. Evans, D.W. McComb, M.J. Mills: Acta Mater., 2019, vol. 172, pp. 55-65.

T. Krol, D. Baither, E. Nembach: Acta Mater., 2004, vol. 52, pp. 2095–108.

A. Bauer, S. Neumeier, F. Pyczak, R.F. Singer, M. Göken: Mater. Sci. Eng. A, 2012, vol. 550, pp. 333-41.

Acknowledgments

The authors would like to thank the financial support of National Key R&D Program of China (Grant No. 2017YFB0702904) and Fundamental Research Funds for the Central Universities (Grant No. FRF-BD-17-017A).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 27, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, Y., Fu, H., Zhou, X. et al. Microstructure Evolution of Multicomponent γ′-Strengthened Co-Based Superalloy at 750 °C and 1000 °C with Different Al and Ti Contents. Metall Mater Trans A 51, 1755–1770 (2020). https://doi.org/10.1007/s11661-020-05652-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05652-0