Abstract

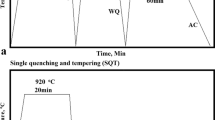

The tensile test is an important test to determine several mechanical properties in which a sample is subjected to a constant strain rate until failure. Properties that are directly measured in a tensile test are ultimate tensile strength, breaking strength, maximum elongation, and reduction in area. The present research compared the tensile properties between austempered SAE52100 steel and quench-tempered SAE52100 steel under equivalent hardness. The experimental results showed that the ultimate tensile strength and yield strength of quench-tempered specimens was higher than austempered specimens. However, the total elongation and area reduction of quench-tempered specimens was lower than austempered specimens. Transgranular quasi-cleavage fracture was found on the austempered SAE52100 steel specimens. While using the austempering temperature of 288 °C, slight plastic deformation with existence of cleavage facets and ductile risers around the edges was obtained. However, while using the austempering temperature of 427 °C, the presence of tear marks on the cleavage facets surrounded by dimples indicated significant plastic deformation or ductile rupture. The fracture analysis could be correlated with the elongation obtained in tensile tests.

Similar content being viewed by others

References

J. Chakraborty and I. Manna: Mater. Sci. Eng. A, 2012, vol. 548, pp. 33–42.

T. Karsch, H. Bomas, H. Zoch and S. Mandl: Int. J. Fatigue, 2014, vol. 60, pp. 74-89.

A. Cree, R. Faulkner and A. Lyne: Mater. Sci. Technol, 1995, vol. 11, no. 6, pp. 566-571.

E. Santos, K. Kida, T. Honda, H. Koike and J. Rozwadowska: Mater. Sci, 2012, vol. 47, no. 5, pp. 677-682.

A. Salemi and A. Abdollah-Zadeh: Mater. Charact, 2008, vol. 59, pp. 484-487.

L. Maddi, A. Ballal, D. Peshwe, R. Paretkar, K. Laha, and M. Mathew: Mater. Sci. Eng., A, 2015, vol. 639, pp. 431–38.

C. Li, L. Han, X. Luo, Q. Liu and J. Gu: J. Nucl. Mate, 2016, vol. 477, pp. 246-256.

A. Anazadeh and S. Kheirandish: Mater. Sci. Eng. A, 2012, vol. 532, pp. 21-25.

J. Junior and D. Santos: J. Mater. Res. Technol, 2013, vol. 2(2), pp. 93–99.

M, Arbuzov and Y. Bushuev: Met. Sci. Heat Treat., 1971, vol. 13(1), pp. 10–13.

Q. Wang, C. Li, H. Peng, J. Chen, and J. Zhang: J. Mater. Eng. Perform, 2018, vol. 27(4), pp. 1485–93.

H. Koike, E. Santos, K. Kida, T. Honda and J. Rozwadowska: Adv. Mater. Rese, 2011, vol. 217-218, pp. 1266-1271.

O. Bannykh, V. Blimov, and M. Kostina: Met. Sci. Heat Treat., 2003, vol. 45(1–2), pp. 43–48.

L. Xu, J. Shi, W. Cao, M. Wang, W. Hui, and H. Dong: J. Mater. Sci, 2011, vol. 6(19), pp. 6384–89.

P. Krishna, R. Srikant, M. Iqbal, and N. Sriram: ISRN Tribol., 2013, vol. 2013, Article ID 515484.

J. Chakraborty, D. Bhattacharjee and I. Manna: Scr. Mater, 2008, vol. 59, pp. 247-250.

R. Kar, R. Horn and V. Zackay: Metall. Trans. A, 1979, vol. 10A, pp. 1711-1716.

J. Zhao, T. Wang, B. Lv, and F. Zhang: Mater. Sci. Eng., A, 2015, vol. 628, 327–31.

J. Chakraborty, D. Bhattacharjee, and I. Manna: Scr. Mater., 2009, vol. 61(6), pp. 604–07.

H. Yang, P. Yao, L. Yang, and M. Shao: Proceedings of the 2017 5th International Conference on Mechatronics, Materials, Chemistry and Computer Engineering ICMMCCE 2017), 2017, https://doi.org/10.2991/icmmcce-17.2017.206.

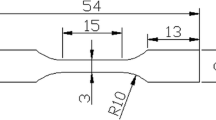

ASTM Standard E8—Standard Test Methods for Tension Testing of Metallic Materials.

A. Basu, J. Chakraborty, S. Shariff, G. Padmanabham, S. Joshi, G. Sundararajan, J. Majumdar and I. Manna: Scr. Mater, 2007, vol. 56, pp. 887-890.

M. Hafeez: Mater. Res. Express, 2019, vol. 6(8), 086552.

D. Karmakar, M. Gopinath and A. Nath: Surf. Coat. Technol, 2019, vol. 361, pp. 136-149.

W. Lee and T. Su: J. Mater. Process. Technol, 1999, vol. 87(1–3), pp. 198–206.

M. Hafeez and A. Farooq: Mater. Res. Express, 2018, vol. 5(1), 016505.

G. Ebrahimi, H. Keshmiri, and A, Momeni: Ironmak. Steelmak., 2011, vol. 38(2), pp. 123–48.

S. Tavares, J. Pardal, G. Souza, C. Oliveira and H. Abreu: Mater. Sci. Technol, 2014, vol. 30, no. 12, pp. 1470-1476.

Z. Feng, Y. Yang, Z. Xu, and Q. Shi: Mater. Res, 2018, vol. 21(4), e20180197.

H. Mousalou, S. Yazdani, B. Avishan, N. Ahmadi, and A. Chabok: Mater. Sci. Eng., A, 2018, vol. 734, pp. 329–37.

Conflict of interest

The authors have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 10, 2019.

Rights and permissions

About this article

Cite this article

Pan, Y., Wang, B. & Barber, G.C. Investigation on Tensile Properties of Austempered SAE52100 Steel. Metall Mater Trans A 51, 1593–1601 (2020). https://doi.org/10.1007/s11661-020-05638-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05638-y